In the process of Hand Soldering, solder is melted by the application of heat. There are various methods of achieving reflow. For hand soldering the default is a soldering iron. In this guide, a basic overview of the soldering process will be explained.

No matter how simple hand soldering seems, soldering is a complicated process in which there is a number of factors that need to be evaluated. To begin with there are two different types of components to choose from: Through-hole components and SMT (Surface Mount Technology) components. Since through-hole technology provides more protection against environmental stress, it has found more application in the military and aerospace industry. SMT components introduce higher density and superior efficiency in the assembly process. Scope of application decides which one is best suited. Commonly most modern assemblies use a mixture of both.

When it comes hand soldering, selection of appropriate tools, equipment and materials are critical. Here is the thorough explanation of some basic tools and materials required in soldering.

- Soldering Station: The soldering station should be protected from ESD (Electrostatic Discharge). When two objects of different potentials are brought in contact with each other, Electrostatic Discharge may occur. This discharge can cause functional damage to the electronic component and assembly. The issue to consider is this may be an instant or a latent failure. No one would like a failure once it reaches the customer or in its working environment. As per the industry standards, it may be necessary to install ESD safe soldering equipment for the safety of the electronic products. In general, it includes anti-static wrist straps and ESD-safe mat. These are grounded using an industry approved documented process. Sometimes an ionisor is used for neutralising charge wherever grounding is not always possible.

- Soldering Iron and Iron Tips: In 2008 the UK adopted RoHS (Restriction of Hazardous Substances) directives. Using compliant standards, soldering irons with temperature control may now be necessary for lead-free soldering. Soldering tips are dependent on their application and come in a variety of shapes and sizes to accommodate different components and techniques. For example, Chisel tip is often suitable for soldering through hole components. Hoof or hollow tips are beneficial in Drag-soldering. Fine or pointed tips are suitable for soldering small components.

- Soldering Wire or Paste: It goes without saying that without an exemption lead-free soldering wire and pastes should be used. Soldering paste is available in different grades (Types 1 to Type 8), which basically differ by particle size. Soldering wire also has various thickness to adopt diverse applications. The size of soldering wire is typically down to the size of the component or land area. Knowing the size to use really comes down to experience.

- Flux: Flux essentially falls into three different categories; Rosin fluxes, Resin fluxes and organic (water-soluble) fluxes. The activity level of Low, Medium or high this covers its cleaning ability or corrosiveness. Commonly they are broken down into 2 types. Cleanable and no-clean fluxes. Which to use is necessary is normally the process engineer’s decision. Fluxes can cause issues to the assembly in its working environment. This is an important but sometimes overlooked procedure.

- Tools and equipment: Tools, equipment and consumables are the last consideration. Are you allowed to use a brass braid for tip cleaning or are you only allowed to use a damp sponge with deionised water. For cleaning of the board a mild solvent is recommended the most common is isopropyl alcohol. For inspection it could be as simple as a magnified eyeglass. A stereo microscope or becoming very popular a camera based inspection system.

We always recommend professional training before you begin to solder. Most companies utilise a trade test designed to test an individual’s proficiency before employment. Equally most companies offer training in house before allowing you to solder a customer’s product.

There are some things to consider before soldering.

We should never handle a PCB (printed circuit board) on the solder able surfaces to contaminate the surfaces to be soldered.

Always use clean gloves or clean hands handling the PCB. On inspection of the PCB ensure no damage to pads, tracks or the laminate surface. You may wish to wipe the PCB using a solvent such as isopropyl alcohol, then apply some flux to aid removing any oxidation during soldering. Set the temperature of soldering iron to the lowest amount possible to achieve solder reflow to the parts to be soldered. Although most common Lead-Free solder reflows around 230ºC. You will need a higher temperature to allow for heating of the areas to be soldered, commonly between 320ºC and 370ºC. After the solder tip is set at an adequate temperature, make sure the tip is cleaned using a sponge or brass braid. Tips need to be free of oxidation and corrosion. These cause a barrier that stops the required temperature needed of the tip of the soldering iron. As an addition, new tips always need to be coated, heated, and then covered with solder before its very first use; otherwise known as ‘tinning’. This thin layer coats the tip and provides a much better transfer of heat from the tip to the solder joint itself. Sometimes referred to as a solder bridge this greatly improves the transfer of heat allowing soldering much faster. If we leave the tip on the board or component too long we will start to see overheating issues. We could damage the board surface, lift pads or tracks, even delaminate or burn the laminate itself.

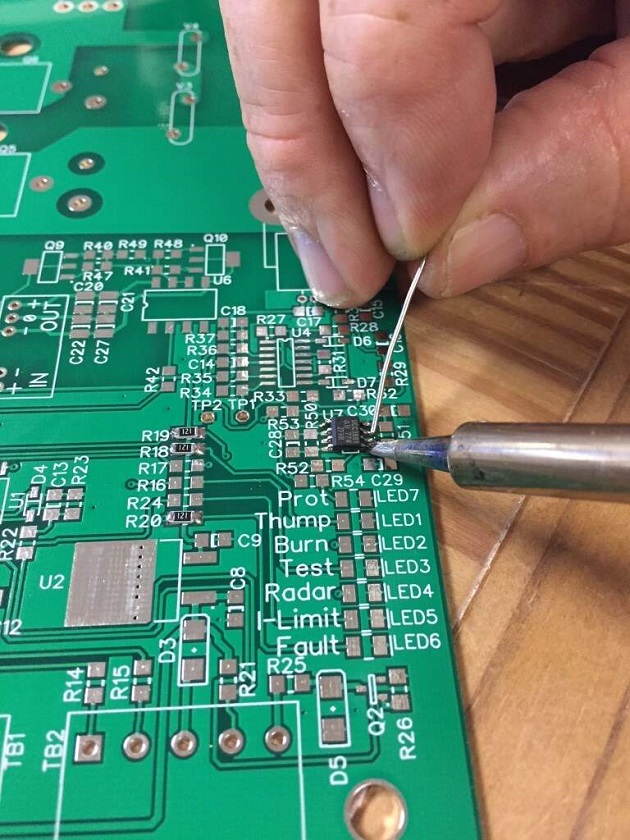

It’s now time to insert your component into PCB. Some PTH (plated through hole) components need to be formed before we can install them. Make sure you have enough lead prude using through the board to solder but not too long to cause issues elsewhere. Now place the tip of the soldering iron to the junction area of the component lead and pad to be soldered. Feed solder from the opposite side of the iron to allow the flux to activate, clean and allow the solder to flow correctly. This can be achieved in around 3 seconds ideally. Insufficient heat and poor contact could lead to poorly created joints, Such as insufficient solder or dry joints. Continue heating before applying some solder to the solder joint itself. The solder should melt and flow smoothly onto the lead and land filling the area to be soldered. Then remove the soldering iron while keeping the joint still, giving it time to cool and solidify.

This point by point soldering technique is slow for some SMT (surface mount terminations) QFP (quad flat pack) or SOIC (small outline integrated circuits). Drag soldering an acceptable soldering process in this instance. The process is to apply flux to all the leads, and then gently drag a bead of solder from the soldering iron across the line of leads to be soldered.

Now it’s time to inspect your workmanship. You should use your company’s documentation or ideally an industry-approved acceptability document. In addition, specific inspection equipment will need to be utilised. You may have an automatic test in place. As a minimum you could also use an ohmmeter to test the solder joint for continuity.

Soldering is not an easy process. Like anything you should be taught first then practice to achieve a high level of competency.

At Advanced Rework Technology Ltd (ART) we can teach you the skills required to meet this level and to succeed in the electronics training industry.

Additionally we offer bespoke and industry certified training for inspection and acceptability to PCB’s. Whether you come to ART or we bring the equipment to your facility we can teach you all you require.