800 V CoolMOSTM P7 – a new benchmark in efficiency and thermal performance

The latest 800 V CoolMOSTM P7 from Infineon sets a new benchmark in 800 V superjunction technologies and combines best-in-class performance with state-of-the-art ease-of-use.

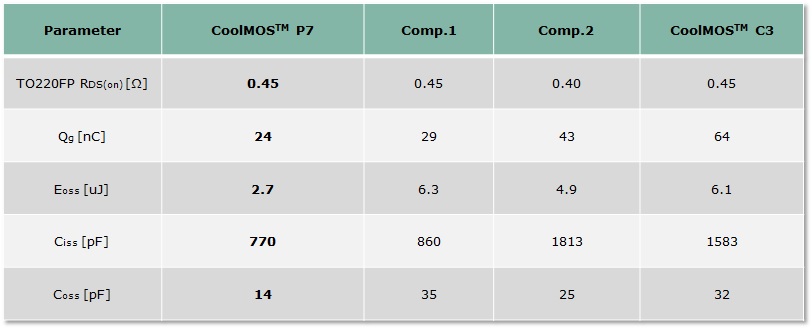

Table 1 gives an overview of key parameters for TO-220 FullPAK products with a maximum RDS(on) rating of between 400 mΩ and 450 mΩ. CoolMOSTM P7 has been fully optimized to deliver best-in-class performance. Compared to the nearest competitors, Qg and Ciss for CoolMOSTM P7 is improved by 17% and 10% respectively. In the case of Eoss and Ciss, a dramatic improvement of 43% to 45% has been observed. These optimizations significantly improve CoolMOSTM P7 efficiency and thermal performance as demonstrated in an 80 W dual stage flyback LED driver application (see Figure 1).

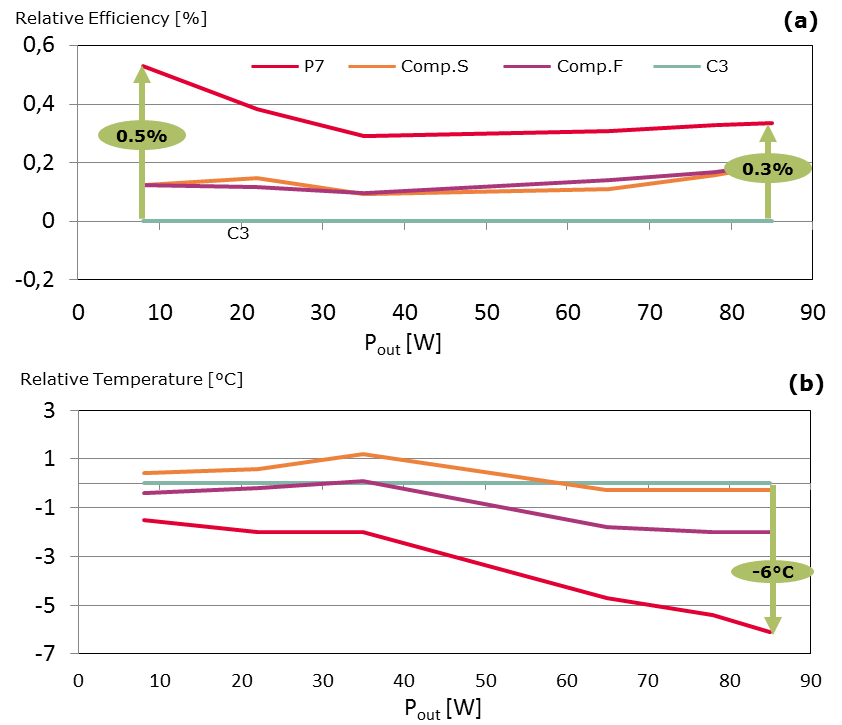

Simply replacing a CoolMOSTM C3 with a CoolMOSTM P7 leads to a better efficiency of 0.5% at light-load and an efficiency improvement of 0.3% at full-load condition (see Figure 1 (a)). The improvement at light-load reduces system idle losses, while at full-load the observed efficiency improvement leads to a better MOSFET temperature by 6°C, thus significantly reducing the overhead for thermal management.

There are typically two ways to realize the high power densities required in today’s market. One way is to use a HV MOSFET at high switching frequencies. This delivers better efficiency, while the highfrequency switching enables the system to use smaller magnetic components to reduce system size. CoolMOSTM P7 is able to address such designs with significantly lower switching losses.

The other method is to use a HV MOSFET with a smaller footprint. CoolMOSTM P7 also supports this approach by offering DPAK products with lower RDS(on) ratings. As indicated by Figure 2, CoolMOSTM P7 offers lower DPAK RDS(on) rating of 450 mΩ, 360 mΩ and 280 mΩ with 280 mΩ as best-in-class, which is 56% lower as than that of the nearest competitors. Better DPAK products help customers save space to increase power density and reduce production costs by utilizing fully automatic assembly processes (when changing from through hole to SMD packages).

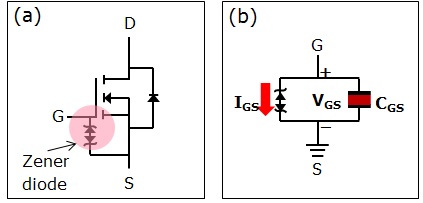

One of the most important features for the CoolMOSTM P7 product family is its integrated Zener Diode, which reduces ESD related failures to improve quality and reliability. The Zener Diode is integrated into CoolMOSTM P7 between the gate and the source (see Figure 3 (a)), where its function is to provide ESD protection. As shown in Figure 3 (b), during an ESD event the voltage between gate and source (VGS) is clamped by the Zener Diode.

Using the HBM ESD model, CoolMOSTM P7 ESD ruggedness is Class 1C for RDS(on) values between 2 Ω and 4.5 Ω. Below 2 Ω the HBM ESD ruggedness is Class 2.

Using the CDM model, ESD ruggedness is Class C3. This ESD protection feature helps reduce ESD related failures during assembly, leading to lower production costs. It also helps reduce field returns by avoiding gate oxide overstress. This is an issue that leads to reduced lifetime of MOSFET; making it possible for a MOSFET that does not fail during assembly to fail in the field.

CooMOSTM P7 offers 12 RDS(on) classes in six package variants for five main target applications: adapter and charger, LED driver, audio SMPS, auxiliary and industrial power supplies. With fine granularity in RDS(on), designers can easily find a part for fine tuning their designs.

Designing with CoolMOS P7

CoolMOSTM P7 combines best-in-class efficiency with state-of-the-art ease-of-use. This product family is ideal for flyback applications with outputs up to 250 W.

Infineon supports the design-in of CoolMOSTM P7 with a variety of application notes and reference designs, including a 45 W adapter demonstration board.