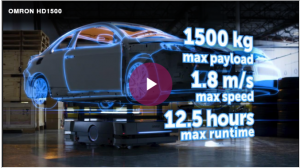

OMRON Asia Pacific, a global leader in industrial automation solutions across Asia Pacific, has launched its new mobile robot called the HD-1500. The robot boasts a heavy payload capacity of up to 1500kg and is the strongest and newest addition to the company’s portfolio of mobile robots. The need for autonomous material handling is becoming greater as more demanding tasks in industrial automation increase while companies face labor shortages along with challenges in implementing new social distancing requirements due to the Coronavirus. The HD-1500 comes off the heels of OMRON’s LD-250 mobile robot, which was launched globally in the fall of 2019.

OMRON’s mobile robots can automatically calculate the best route for material transportation while navigating safely around people and obstacles without the use of magnetic floor tapes nor other guides. The new HD-1500 mobile robot has a 1500kg payload capacity which can be used to transport large automotive components, such as, car chassis and voluminous pallet size payloads – things that would have traditionally been moved using forklifts.

With the release of HD-1500, OMRON’s mobile robots achieve a seamless lineup of models that can transport a wide variety of items – from components to WIP (work in progress), finished products, and heavy material. OMRON’s industry-first “Fleet Manager” can control up to 100 mobile robots with different sizes, configurations and payload capacities under one system, thus enabling customers to utilize the HD-1500 together with OMRON’s existing robots – LD-60/90 and LD-250 – to automate the complex material transport and logistics applications with the optimum allocation of robots without traffic so that they can increase the total efficiency of material handling inside the factory.

The HD-1500 offers 360-degree safety coverage promoting a collaborative and safe working space. With the release of HD-1500, the stop position accuracy of the CAPS (Cell Alignment Positioning System) has also been improved. The addition of the HD-1500 also strengthens OMRON’s position as a global leader in autonomous mobile robotics.

“OMRON has invested many resources in helping customers realize an advanced and flexible manufacturing environment with our robotics technologies since the acquisition of U.S. based robotics company Adept Technology, Inc. in 2015, as part of OMRON’s ‘innovative-Automation’ initiative,” said Motohiro Yamanishi, Senior General Manager of the Robotics Business Development Project at OMRON’s Industrial Automation Company, adding, “The new HD-1500 mobile robot will be key in advancing that initiative a step further, by giving customers more choice when safely automating their material transport operation. This is an area rapidly being enhanced with mobile robots in industries worldwide as a method not just to meet labor shortage challenges but to manage the risks associated with the spread of the Coronavirus.”

“Onsite logistics, the movement of products and material within the factory and warehouse, is becoming a real bottleneck for many companies due to the frequency and tediousness of the job, compounded by rising labor costs and the need to meet social distancing protocols. Fast-paced manufacturing environments require speed and flexibility. OMRON’s HD-1500 mobile robot can help companies solve this issue because it can work 24 hours a day tirelessly, punctually, and safely in the same environment as people.” said Tom Mathias, President, and CEO of OMRON Robotics and Safety Technologies, Inc., a leading provider of robotics and safety solutions for manufacturing industries and part of OMRON’s Industrial Automation Business.

Highlights of HD-1500:

- Higher Payload and sturdier Structure:The HD-1500 addresses the market need to move pallet size payloads in manufacturing facilities and reduces the need for a forklift. Built with sturdy metal skins, the HD-1500 is robust and able to withstand heavy unintended external impacts. Onboard sensors are well protected as the robot completes demanding tasks.

- Highly Mixed Fleet:Customers still obtain the ability to manage mobile fleets up to 100 robots, including the HD-1500. OMRON’s Fleet Manager allows a diverse mobile fleet to be controlled with the same system while achieving high performance and compatibility.

- Faster ROI:As the need for greater efficiency in the workforce increases, the HD-1500 offers a solution to automate complex and dangerous tasks. Organizations can begin to phase out forklifts and safely transport large pallets containing finished goods, voluminous materials in the food and commodities industry, and automotive frames. Workers can now focus their attention on more vital tasks; allowing customers to load more, making fewer trips with heavier batches, and increasing ROI. With the HD-1500, customers can do more with less equipment.

- Customizable:OMRON mobile fleets can be more diverse and still be controlled through the same system. The HD-1500 fits seamlessly into the larger OMRON mobile fleet, working together with other robots to optimize traffic management, battery management, and routing of vehicles. Customers can add the HD-1500 to their fleets without worrying about safety, compatibility, or performance.

Additional features:

- Battery charges in 39 minutes to realize greater efficiency and less downtime.

- 360-degree safety scanning lasers used for simultaneous localization and safety functionality.

- Superior navigation using adaptive safety zones from LiDAR technology

- Improved CAPS technology allows for better accuracy and repeatability for docking

For more information, visit www.web.omron-ap.com