Global technology leader Laird has expanded its thermoelectric module (TEM) product family to protect critical electronic devices in emerging applications found in high-temperature environments. This typically occurs in outdoor environments where heat generated from surrounding electronics exceeds the temperature of sensitive electronics with maximum operating temperatures of 60~70 degree C. The HiTemp ET Series delivers spot cooling to ensure the maximum temperature of the device is not exceeded in ambient environments greater than its maximum operating temperature.

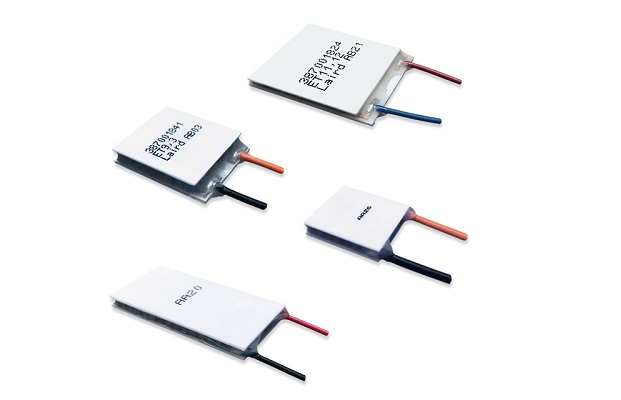

The HiTemp ET Series launch includes 53 models for engineers to choose from with a wide range of heat pumping capacities, geometric form factors and various input voltages to cover the wide range of applications Laird is gaining exposure to. Laird’s enhanced TEM construction prevents copper diffusion, which commonly occurs for standard grade TEMs in higher temperature environments and prevents degradation in their performance. The HiTemp construction also does not sacrifice performance for reliability like other high-temperature modules on the market. The product series maintains a high coefficient of performance (COP) to allow for maximum heat rejection into air environment even with poor heat sinking.

Many sensitive devices, such as lasers and CMOS sensors, are designed into autonomous systems for collision avoidance in vehicles and drones. Digital light processors (DLP) are used in 3-D machine vision, advanced lighting systems and projectors that may also require cooling in outdoor environments where ambient temperatures exceed its maximum operating temperature condition.

“Depending on the application, active cooling may be required to maintain temperatures of sensitive electronics below their maximum operating temperature. The HiTemp ET Series is a preferred cooling method due to its proprietary construction that has shown to not degrade in this environment,” said Anders Kottenauer, Senior Vice President of Laird’s Thermal Systems Business.

For more information, visit lairdtech.com.