Combining two devices using two different temperature measurement technologies, Fluke Process Instruments provides the glass industry with more information on high-value applications like float glass manufacturing, glass tempering, and windshield forming and laminating. Fluke Process Instruments provides comprehensive temperature profiling and imaging solutions for high-value glasses, including low-E glass.

Temperature profiling runs with a data logger enable operators to quickly optimize furnace settings for new products and to identify problems with burners or airflow. They are complemented by a thermal imager installed at the furnace exit for 100 % production monitoring and traceability. Datapaq Furnace Tracker profiling systems travel through heat-treatment and quench processes. They record the product temperature curves via up to 20 thermocouples cemented to the glass pane.

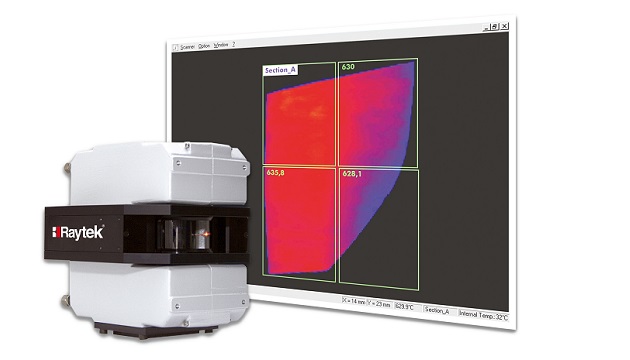

These industry-specific profiling systems consist of a data logger, a thermal barrier, and software with advanced analysis, reporting, and archiving functions. The manufacturer offers the largest range of thermal barriers in the market and will advise customers on which system setup to use for their applications. The other measuring device, a Raytek MP150 infrared linescanner, scans each glass pane when it exits the furnace. It generates a thermal image and immediately shows up hot and cold spots.

The series comprises various different spectral models, allowing even low-emissivity glass to be monitored. In contrast to thermal cameras, the linescanner needs only a very narrow field of view. It is therefore ideal for manufacturing lines with furnace and quench installed in close proximity.

For more information, please visit www.flukeprocessinstruments.com.http://www.flukeprocessinstruments.com