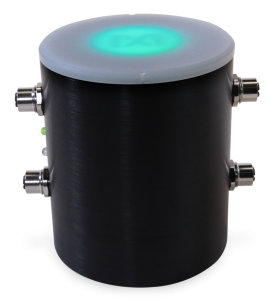

Using this transceiver, Maxim has also built the first public and fully IO-Link-compliant, 4-port IO-Link master reference design.

The reference design has four robust female M12 connectors, the most common connector used for IO-Link, and ships with two black IO-Link cables to quickly connect to IO-Link compatible sensors and actuators. An AC-to-DC (24VDC/1A) power-supply cube is capable of providing greater than 200mA simultaneously to each port and greater than four times that amount if the other ports are unused. A Micro-USB connector underneath the enclosure allows for quick connectivity to a Windows® PC.

IO-Link reference designs such as the ones described above help speed up the design and development of IO-Link based sensors within customers that are still beginning to embrace this fast growing technology.

CONCLUSION

Industrial IoT is at an inflection point – we see some factories that are getting hyper connected and many others which are still in the evaluation mode. As factories become digital, smart and relevant sensor data will be the basis upon which manufacturing and even enterprise level software will run optimization and other algorithms.

As sensors measure even more parameters and have to communicate with the controller/PLC, the need for a low-cost, robust, and open communication standard will be important. IO-Link checks all of these boxes and has the potential to become the dominant factory automation standard for the pervasive, smart sensor world that is emerging.

REFERENCES

1 http://www.io-link.com/en/Technology/what_is_IO-Link.php?thisID=76