In addition to clear standards for industrial infrastructure, the production of the future requires ever more intelligent systems and processes. The field of activity ranges from the collection of sensor data, analysis in Edge environments or in Clouds, initial results presentations in connection with Predictive Maintenance, and through to Machine Learning and Artificial Intelligence (AI). With HARTING “HAI powered Connectivity”, the HARTING Technology Group creates continuity from the Cloud to the field level – and thus positions itself as the enabler of Integrated Industry towards the Future Factory.

Artificial intelligence (AI) is ubiquitous. AI is considered the key driving force behind the Digital Revolution. In the production sector, the technology has now outgrown its infancy and has thus sounded the starting gun for AI systems within industry. For HARTING, this year’s trade show motto of “Integrated Industry – Industrial Intelligence” means the convergence of human and artificial intelligence into industrial intelligence in order to create added value for customers. HARTING products from “HAI powered Connectivity” are smart, clever and easy to use.

Standards facilitate communication

In the factory of the future (Future Factory), different components and products need to be able to communicate with each other and exchange lots of data to enable new services. Standards facilitate communication here.

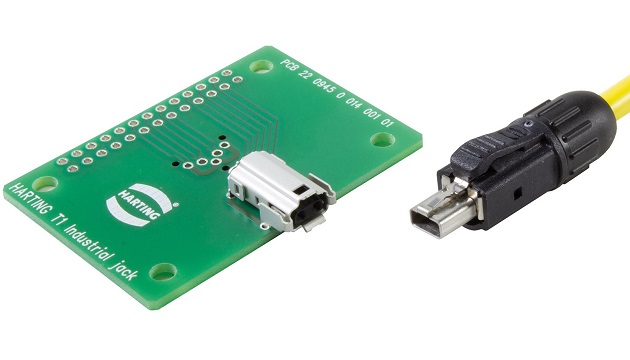

The technology group also has IIoT firmly in its sights. The group developed the T1 Industrial connector to meet the demand for an end-to-end communication infrastructure and thus reach all industrial internet subscribers of the IIoT in future. HARTING has already used the T1 to define the IEEE connector standard for Single Pair Ethernet deployed in the industrial sector. This is an intelligent connectivity solution that brings miniaturised sensors and actuators of a new I4.0 automation into the network and thus into the Cloud as well.

Also focus on solutions for Edge and Cloud

To ideally achieve all the elements of a modern network, more and more customised connector solutions are needed to bring power to the edge, e.g. the Han 1A. The world’s smallest rectangular connector and the newest member of the Han connector family ideally meet the demands of an ever shrinking device world.

With specific application scenarios, HARTING uses the example of a working plastic injection moulding machine to demonstrate services such as Injection Mold Ident for tool recognition or energy management with the MICA to achieve increased productivity in connection with energy requirements. Whether Cloud-bound or “on the edge”, HARTING partners and system integrators from the MICA.network are once again represented in Hannover and will be presenting additional applications from a wide variety of industry segments.

HARTING’s Single Pair Ethernet series products

HARTING is driving the development of Ethernet connectivity for tomorrow’s networks. Single Pair Ethernet (SPE) is on everyone’s lips in the industrial cabling market. HARTING supplies the appropriate standardised interfaces in order to actively promote the Design-In of the next generation of automation devices.

As an enabler of IIoT, HARTING is thus taking the step from a technology trend to a real application and customer solution. With an interface standardised according to IEC 63171-6, the technology group is consistently going down the path of recognising trends, defining standards and delivering reliable products.

But what’s actually behind Single Pair Ethernet? Generations of network engineers, planners, installers and users have learned that Fast Ethernet 10/100Mbps requires two wire pair cabling and that Gigabit Ethernet requires four wire pairs. The new Single Pair Ethernet is now pushing a technology into the market that can transmit these TCP/IP-based data streams via just one pair of wires.

However, the necessary eco-system also requires partners who actively co-support this development. HARTING wants to market Single Pair Ethernet (SPE) solutions with its technology partner HIROSE, with which the HARTING ix Industrial has already been successfully placed on the market. Likewise, TE Connectivity will co-develop products for the future SPE infrastructure as a cooperation partner.

Small, robust and flexible: Han 1A

HARTING presents a new space-saving industrial interface at the world’s largest industrial trade fair: the Han 1A is significantly smaller than the hitherto smallest rectangular HARTING industrial connector, the Han 3A. Despite its small dimensions, the connector offers powerful solutions for all lifelines in industry. Thanks to the simple “Click & Mate” principle, users also save valuable working time during assembly.

The new interface uses black plastic housings and can be equipped with coloured coding. It requires little space and is very versatile, as it integrates contacts for data, power and signal transmission. In addition, it features a flexible connection technology that offers an optimum solution both for on-site installation – screw contacts – as well as crimp contacts for the pre-assembly of separate units. The combination of few basic elements results in simple and efficient interfaces, e. g. for mechanical engineering, automation, robotics, medical, energy and traffic engineering.

HARTING accelerates e-mobility

The infrastructure-electromobility ecosystem requires intelligent data processing and analysis systems in order to be able to offer the services that are desired. Among others, this includes information as to which next charging station is best suited with regard to the battery status or which energy provider currently has the cheapest rate.

Intelligent charging systems, which fuel a vehicle virtually autonomously, also require data from a wide variety of systems. Charging infrastructure solutions such as the Type 2 connector for AC charging or the Combo for fast DC charging are already adapted for such systems. At the industrial trade show, HARTING will demonstrate “live” how automatic charging works. A KUKA charging robot guides the HARTING charging connector into the vehicle socket and stops the charging process as soon as the drive battery has reached the required charge level. This makes the vehicle ready for use again after a short time, providing a solution for a variety of applications such as vehicle fleets or parking garages, where cramped space would virtually rule out manual charging.

The MICA edge computer is used very close to the application here as well, among others to operate charging management or to safeguard billing systems with secure communication.

Together with HARTING partners Rinspeed, KUKA, innogy, SAP and MHP, the technology group will be presenting a wide variety of solutions in the infrastructure e-mobility ecosystem. Swiss car visionary Frank M. Rinderknecht is slated to present his latest vehicle study, the “microSNAP”, in Hannover. The bold idea behind the “microSNAP”: chassis, drive (“skateboard”) and superstructures (“pods”) can be separated and quickly swapped out.

Economy has cooled

Board chairman Philip Harting addressed business development at the Technology Group. Risks such as the US-China trade wars, punitive tariffs, Brexit and slowing global demand had been felt in the day-to-day business. “The economy has cooled down further since the end of last year,” Harting said at the press reception in Hannover. He added that achieving the December 2018 forecast of almost 5% growth in sales for the 2018/19 financial year would be a challenge.

For more information, visit: www.harting.com