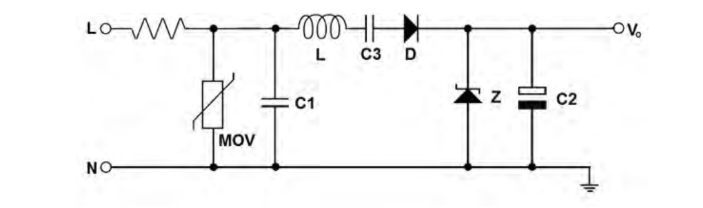

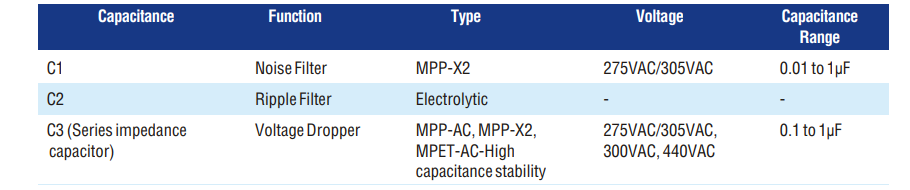

A capacitive power supply is the best solution for a low-cost energy meter. It works on the principle of reducing the line voltage (voltage dropper) by having a series capacitor between phase and neutral. Current flowing through this capacitor is inversely proportional to the impedance of the capacitor as given by the formula:

Impedance (Z) = 1/(2πfC)

f is the line frequency and C is the capacitance of the series impedance capacitor.

The output of the capacitor needs to be rectified to generate the DC output signal

The output current of the rectifier circuit has ripples of positive half-cycles, so a bulk capacitor C2 is used to provide a ripple-free DC signal to the system. This capacitor provides smooth output voltage until the amount of load current is less than the charging current.

To obtain a higher output current, increase the capacitor value C3 on the AC line.

A filter network consisting of C1 and L1 removes noise from the input AC signal

Reliability under hot humid conditions

Power utilities around the world are rolling out smart meters in order to enable automated meter reading and optimized energy management. These meters can be located in any area like high-temperature area, high humidity areas. Some of our customers manufacturing industrial energy meters informed us that they were facing problems of change in capacitance value in capacitors used in energy meters in coastal areas.

How the capacitor fails

The capacitor generally fails in three modes that directly affect the capacitance value:

- Capacitor short

- Capacitor open

- Degradation of capacitance

Capacitor short

The capacitor gets short-circuited with very high loss factor. It occurs when the dielectric breaks down completely and film melts. It is a very severe case. This is not the cause for the observed failure in the capacitors since here the failure is due to capacitance drop.

Capacitor Open

The capacitance value drops by more than 30%. When the capacitor is opened, there is no damage to the film metallization. This failure is due to a process defect, either in metal spray operation or due to weak welding of terminals. This is not the problem in this case since there is damage to the film metallization.

Degradation of capacitance

The capacitance value drops to some extent. There two reasons for capacitance drop:

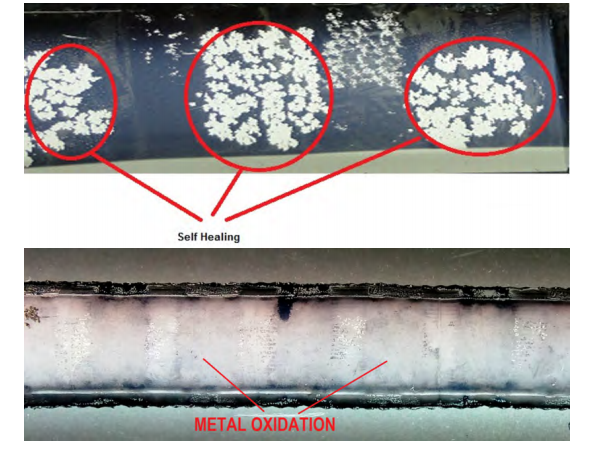

- Excessive self-healing

The self-healing occurs only at the weak points of the dielectric leaving other areas of metallization healthy. It is mainly due to voltage spikes/stress and temperature.

- Metal oxidation

Metal oxidation occurs under the humid condition and it is the result of reaction between film metallization (very thin layer on film) and humidity. In this case the capacitance value drops and dielectric losses increases.

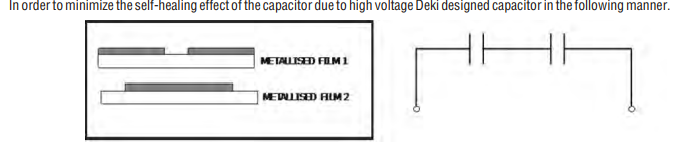

This makes it two capacitors in series which divides the voltage by half thereby decreasing the self-healing effect of the capacitor. Deki discussed the issue with the film supplier who specially developed a humidity resistance film for this capacitor. Both the design changes combine to give very good results in hot and humid conditions. To avoid metal oxidation, we have changed the material for metallization on film, going with aluminium metallization which is less reactive to humidity.

Comparison between high stability capacitor and normal capacitor

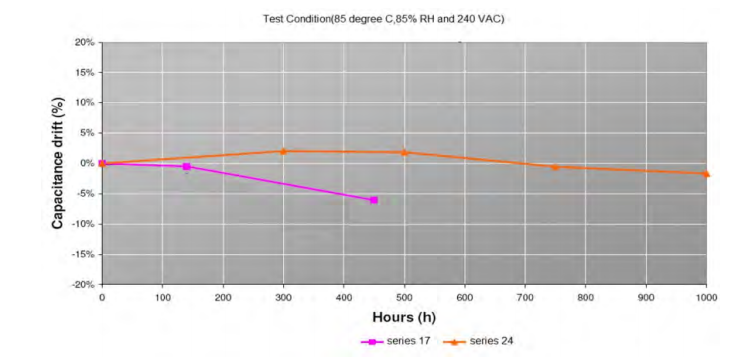

The graph below shows the difference between our normal capacitor and heavy duty capacitor when we applied 240VAC at 85°C and 85% RH.

For more information, visit: www.dekielectronics.com

For more information, visit: www.dekielectronics.com