DAEYONG SHIM

DAEYONG SHIM

Vice President, Head, Automotive Business SK hynix Inc

The Automotive Revolution

As the Automotive industry continues to develop beyond the concept of traditional cars, the industry is entering a revolutionary period. Future mobility is quickly approaching on the horizon, and with the introduction of Advanced Driver Assistance System (ADAS), In-Vehicle Infotainment (IVI), multi-camera vision processing and self-driving cars, ultra-huge computing processing has become a necessity.

19th-century internal combustion engines combined with 20th-century electrical systems have paved the way for the automotive technology of the 21st-century, which is now undergoing a massive digital transformation. Cars today, and tomorrow, will be more Connected, Autonomous, Shared and Electric than ever before, which is why this transformation has been dubbed the ‘CASE Revolution.’

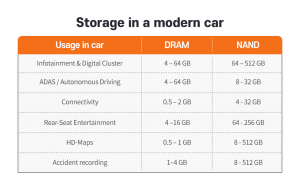

The CASE Revolution is characterized by complex and efficient interconnectivity as well as integrated systems inside and outside of the vehicle. Enabled by the advancement of automotive electronics, trends like the increased adoption of infotainment systems, long-life batteries and ultrafast 5G networks all require high-capacity memory. Consequently, they are driving massive demand for DRAM and NAND solutions in the global automotive market.

The Next Generation of Automobile Memory

The surge in electric vehicles (EV) and hybrid vehicles, accompanied by the emergence of ADAS, Graphic Instrument Cluster (GIC), infotainment systems and fully autonomous driving solutions has created a need for Electronic Control Units (ECU) – automotive computer controllers used to receive and process signals from sensors and export control commands to the actuator to execute.

In traditional automotive Electrical / Electronic (E/E) modular architecture, each distributed ECU handles a single function independently. As modern vehicles contain many electronic functions, the number of ECUs increases dramatically from low/mid-end cars (around 30) for high-end cars (around 100). As a result, integrated ECU controllers like vehicle integration platforms and functional centralization have been introduced as a way to reduce cost and maximize power efficiency in four main areas: Powertrain, ADAS, Body, and IVI.

As the autonomous driving level evolves and the variety of IVI contents diversifies, the amount of data being processed has increased tremendously – this is a result of simultaneous complex cross functions and a connected network. Consolidation of ECUs into DCUs (Domain Control Units) reduces cost, weight and power consumption. DCU is a highly integrated domain control unit that implements advanced competencies like multi-sensor fusion and 3D localization. For example, vision processing for Level 4~5 Autonomous driving capabilities can contain up to 12 cameras with resolution up to 8M pixels, 60 Frame/sec refresh rates, and 16bit depth, allowing the data streaming rate to reach almost 10 GB/s.

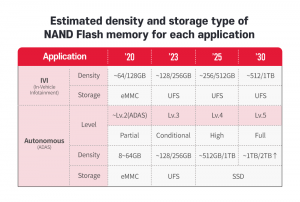

Automotive LPDDR4 and LPDDR5 were originally designed for mobile applications, however, they’re being supercharged to meet auto-grade qualifications that are more demanding than for mobile applications. The LPDDR5 in particular has been adapted for much bigger displays in the latest vehicles to manage increasingly sophisticated navigational images and the control area of cockpit units. Furthermore, the digital cluster, front and rear sensors, and driver monitoring system utilizing in-cabin cameras, which are derived from traditional IVI, all require LPDDR5 DRAM’s high-end functionality.

However, higher computing and communication performance requires more electrical power demand – at least up to 4 kW. As tightening CO2-emission regulations for internal combustion engines (ICE) and range requirements for Battery Electric Vehicles (BEV) limit the overall power consumption, future E/E architectures and automotive memory must become more energy efficient. The next generation of automobile memory needs to push the envelope in bandwidth, latency, power, and capacity.

High-capacity NAND Flash memory modules also play an important role in many automotive applications and systems. When accidents happen, it is extremely important to capture the data of certain sensors in real-time and store it permanently in memory. Similarly, ADAS should draw the driver’s attention to potential dangers – like cars or other obstacles being too close. Adaptive functions can automatically switch on the headlights, regulate driving speed, initiate emergency braking, alert the driver to surrounding vehicles, keep the vehicle in its lane and even monitor a driver’s “blind spot.” Furthermore, the settings of the infotainment system must be instantaneously stored so that they are not lost in the event of a power failure. Both GIC and infotainment systems work with high-quality graphics and therefore require large amounts of overlay data. All these functions use non-volatile memory.

Increasingly, automakers and semiconductor companies are joining forces as the auto industry progresses rapidly from merely adding electronics to actually building self-driving vehicles. While it grows with the industry, automotive memory must also continue to maintain the highest safety protection and superior quality. Making significant strides in the automotive semiconductor market in 2020, SK hynix is relentlessly pursuing the best performance and the highest quality.

To provide this, SK hynix is committed to supporting AEC-Q100 and building up its standard process – from designing in the R&D stage to manufacturing following IATF 16949. There is also another standard called Automotive Software Performance Improvement and Capability Determination (ASPICE), which is an established framework for measuring process quality. Functional safety (ISO 26262) is another important aspect of safety-critical applications. SK hynix is working hard to meet all these standards, and only when we have achieved them can our products obtain the certifications and qualifications required in the automotive sector.

These automotive industry standards help ensure clear communication among stakeholders throughout the product lifecycle. The traceability not only helps product designers, engineers and testers develop with confidence, it also makes the market safer, and vehicles more reliable. Adhering to these standards will lead to better quality, higher efficiency, and lower failure rates.

SK hynix’s automotive memory is enabling technology for the development of ECC (Error Correction Code), BIST (Built-In Self-Test), and CRC (Cyclic Redundancy Check), and SK hynix is also creating a bit-cell that is more temperature resistant and introduces error correction within DRAM die that have lost their charge between refreshes. SK hynix is even applying the error correction function not only within the DRAM die but also in the DRAM interface to mitigate possible errors in automotive memory.

For NAND Flash, SK hynix applied TLC (Triple-Level-Cell) 4D NAND with PUC (Peri. Under Cell) technology to automotive UFS to guarantee its high-performance. It boasts faster random write and read speeds than eMMC 5.1 interface, enhancing the performance of IVI systems and instrument clusters. Automotive UFS is a high-performance storage interface ideal for advanced automotive systems that need ultra-fast boot capability and automotive-grade reliability.

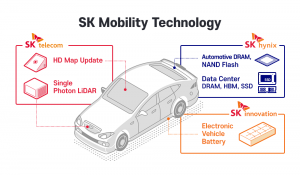

In conjunction with other SK Group affiliates, such as SK Telecom, SK Innovation, and others, SK hynix will lead the e-mobility industry’s revolution and contribute to the creation of both economic and social value with advanced and environmentally friendly semiconductor technologies.

SK hynix’s advanced, high-quality automotive memory products will push forward a new e-mobility era and deliver superior convenience to drivers around the world.