Worldwide silicon wafer shipments slipped 9.0% quarter-over-quarter to 3,265 million square inches in the first quarter of 2023 and 11.3% from the 3,679 million square inches recorded during the same quarter last year, the SEMI Silicon Manufacturers Group (SMG) reported today in its quarterly analysis of the silicon wafer industry.

“The decline in silicon wafer shipments reflects softening semiconductor demand since early this year,” said Anna-Riikka Vuorikari-Antikainen, Chairman of SEMI SMG and Chief Commercial Officer at Okmetic. “Memory and consumer electronics have seen the largest drops in demand while the market for automotive and industrial applications remains more stable.”

Silicon Area Shipment Trends – Semiconductor Applications Only

| Millions of Square Inches | ||||||

| 4Q 2021 | 1Q 2022 | 2Q 2022 | 3Q 2022 | 4Q 2022 | 1Q 2023 | |

| Total | 3,645 | 3,679 | 3,704 | 3,741 | 3,589 | 3,265 |

Data cited in this release include polished silicon wafers such as virgin test and epitaxial silicon wafers, as well as non-polished silicon wafers shipped to end users.

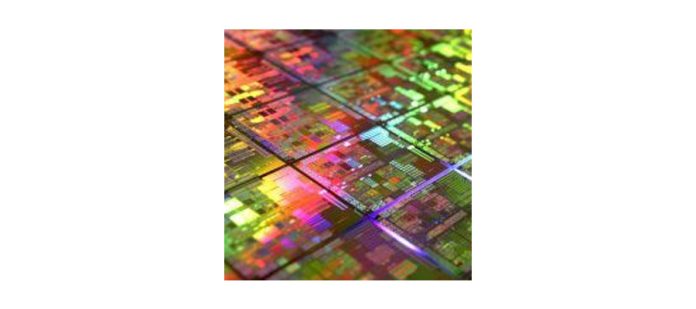

Silicon wafers are the fundamental building material for the majority of semiconductors, which are vital components of all electronic devices. The highly engineered thin disks are produced in diameters of up to 12 inches and serve as the substrate material on which most semiconductors are fabricated.

The SMG is a sub-committee of the SEMI Electronic Materials Group (EMG) and is open to SEMI members involved in manufacturing polycrystalline silicon, monocrystalline silicon or silicon wafers (e.g., as cut, polished, epi). The SMG facilitates collective efforts on issues related to the silicon industry including the development of market information and statistics about the silicon industry and the semiconductor market.