Of the country’s total demand for electronics, approximately 60 percent of the products and 80percent of the components are imported. Having said and done India’s electronics manufacturing has been unable to respond to the rising demand. Policies for electronics manufacturing have been formulated with a long-term vision but their implementation has lacked the same tenacity for a long-term sustained approach for promoting high value-added manufacturing.

India’s imports of electronic goods grew 31 percent between April and October 2017 while the trade deficit reached close to $100 billion during the April-November period of 2017. This is an ominous sign. If the situation doesn’t change it will increase the trade deficit further.

There are various factors that have kept these goals from being met.

Editor-in-Chief

ELE Times

The government needs to bring the duties on components down to the level of the product, thus improved upon the Inverted tax structure for electronic goods.

Foreign Direct Investment (FDI) in electronics is less than one percent of the total FDI inflow because of onerous labour laws, delays in land acquisition and the uncertain tax regime have kept investors at bay. Large Foreign or Domestic investments in electronic component manufacturing will happen only if India offers a cost advantage in component manufacturing.

The procedures for cross-border trade work against the competitiveness of Indian producers. The numerous forms, fees, inspections and the associated time discourage domestic producers from exporting and keep them out of the international supply chain.

Majority of components are allowed for import at zero or minimal duty. This policy has encouraged low value-added manufacturing/assembling but simultaneously has stymied the growth of the existing component manufacturing base and FDI in the sector. The government should look into the policy recommendations by ELCINA as to divide components into ITA-1 and Non-ITA 1 categories and further into two categories of below 30% Value Addition and >30% Value Addition. Target minimum 10-15% protection to components with <30% VA and 15-20% protection with >30% VA.

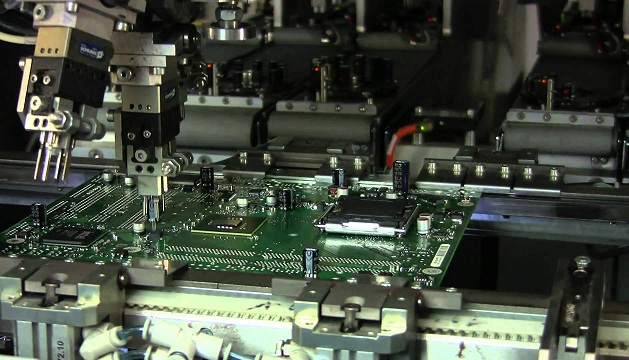

The Make in India campaign can only be successful when the thrust will be on Design in India. This will drive demand for indigenous components/ PCBAs and assemblies.

Set Top Boxes are a major manufacturing opportunity and need special attention and protection from unfair imports through FTA routes.

A dedicated fund for the development of Component Manufacturing ecosystem should be floated.

A dedicated EMC policy for component manufacturing may be formulated. Here land will remain with the government provided on favourable long lease terms. Such EMC’s could focus on high volume and high growth component groups such as PCB’s, LED’s, Sensors, Wound Components, Switches, and Relays.

It may be proposed that Central Government should extend Credit Default Guarantee covering 25% of the value of the sale of domestically manufactured components and support local manufacturers by incentivizing the purchase of their components/products.

To boost electronic manufacturing in the country it is important to have adequate PCB manufacturing capacity that meets the need of the industry at competitive prices thereby preventing excessive dependence on imports. The main reason for lack of large investments in PCB manufacturing is that PCB’s are subject to zero BCD under ITA-1 and most PCBA’s are also imported at zero duty.

There are various government schemes to encourage domestic manufacturing which provide tax and tariff concessions, investment subsidies, preferential market access in government procurement and export subsidy and levy the import duty on various electronic items. Still much needs to be done towards removing barriers that discourage exports and creating a reputation for stable and predictable rules. Apart from it, there are various recommendations from industry and associations. The Government should take a serious look of such suggestions before formulating New National Policy on Electronics.

Moreover, policymakers need to understand that normal course of action seldom fetches the desired results in the stipulated time frame. We are at the historical crossroads where mere mundane decisions only procrastinate the process. For the electronics industry, we have an extraordinary situation that has to be dealt with extraordinarily.