Your next evening dress could turn out to be your hero and get you help in time if trouble is lurking around. Thanks to recent advances in organic printed electronics developed for products ranging from evening wear to performance apparel, wearables are about to get lighter, more flexible and extremely versatile.

At ISPO Academy Conference held at the organization’s annual Munich winter sports industry trade show, the session, titled “Textiles 4.0: Flexible and Printed Electronics for Smart Sportswear,” was presented by a group of lecturers led by Robert Lindner, director of the Frankfurt-based Organic and Printed Electronics Association. The group shared with the audience a sampling of next-gen technology that will serve a broad array of applications.

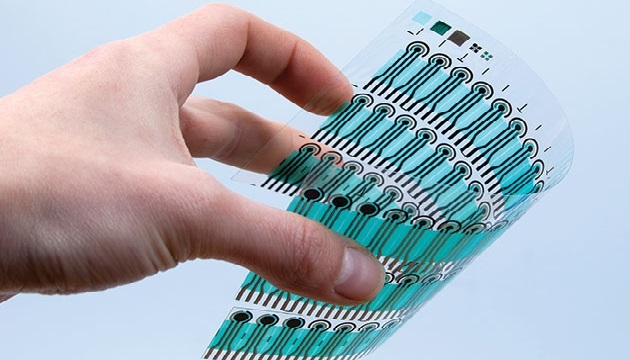

The enhanced functionality that new printed microelectronics technology will bring to wearables has required important collaboration between fields of printing, chemistry and design, and will take the segment to the next level, according to Lindner. Flexible active or passive sensors for electrodes integrated into textiles enable the creation of more comfortable, lighter weight and stretchier fabrics for smart garments.

New apparel and sport developments

The many developments underway, include smart headbands and wristbands with integrated lighting and sensors that can detect motion, speed, acceleration and give feedback in the form of a display. Tiny OPV, or Organic Photo Voltaic cells printed on fabric, can also serve as light sources and allow for the harvesting of energy, like in a phone charging T-shirt or a tent that absorbs energy from the sun during the day and stores the power to be used later.

Miguel Ribeiro of CeNTI, the Center for Nanotechnology in Portugal, which has done extensive work integrating sensors into textiles, discussed the impact OLEDs, or Organic Light Emitting Diodes, will have on wearables. One series of projects involves printing heating systems on textiles to create warm jackets and gloves for outdoor sports and workwear garments. The systems also have touch-sensitive sensors that can act as proximity switches to indicate whether the product is on or off.

Another is a lymphedema compression sleeve integrated with stretchable printed sensors that can detect, measure and mitigate post-surgical arm swelling, a dangerous problem if not caught and treated in a timely manner.

Also in development is outerwear that monitors environmental and bodily functions to ensure that the wearer is safe and comfortable, and communicates that back to a home base if help is needed. This would be ideal for military, firefighters and other first responders, and extreme athletes, like climbers.

Ulrich Herleb of Rollo, Missouri-based Brewer Science, another provider of flexible printed sensor solutions, described how far wearables have come in the past several years.

“First we had the pedometer, which was an electromechanical device that counted steps. Now we have the smartwatch, which can also measure other things, like heart rate or distance traveled,” Herleb said.

He predicts that sensors embedded in feet or elsewhere in the body might do the job in the future and that over time, people will be getting more and more feedback from wearables.

Athletes and their coaches might use movement or impact data collected during training or competition to improve performance. Flexible sensors in a golf or batting glove might help a golfer or baseball player correct his or her swing. A flexible band placed in the knee area of a skier’s pants could indicate a bend angle—an important indication of positioning and technique. The trainer of a football team might use helmets embedded with the lightweight sensors to transmit information that would help prevent or treat concussions.

The Holy Grail that no one has yet figured out, according to Herleb, is “measurement of blood pressure–but people are working on it.”

Amping up the light and color

Erno Langendijk has developed the Lyteus pilot line at the Holst Centre in the Netherlands that prints OLEDs (Organic Light Emitting Diodes) on extremely thin, lightweight, flexible plastic which, he says, are easy to integrate into products and will increase the visibility of printed electronics–literally. He noted how cool it would be “to have light peeking out from under your snowboard as you traversed the slopes. This kind of visibility might also help you get rescued if you get lost on the trails!”

The OLEDs in the pilot line, which are now being sold for product development, can be very small or very large, and laser cut into any shape. They have a small bending radius, are heat and shock resistant, and are expected to drive new product innovation.

Langendijk has made an ultra-thin, 1.8-meter x 30-centimeter roll on the pilot line, and will eventually be able to make OLEDs up to 100 meters long in any color:

“These can be transparent or reflective, and they create light, they don’t just reflect it. So you can have a light emissive patch integrated into a garment,” he said, adding, “You can’t go anywhere to get these devices. We are the first ones in the world making them.”

Growth outlook and challenges ahead

Just how far away are we from this technology driving huge growth in wearables?

Brewer Science predicts that wearables volume growth will accelerate over the next few years, driven by growing use in smart shoes, cameras, wristbands and the Internet of Things.

Wolfgang Mildner of MSWtech feels the developments in printed electronics will allow for easier-to-use, longer-lasting and more cost-effective wearables.

A couple of major obstacles still need to be overcome before this happens, however, according to the panelists.

The new technology, though lighter and more flexibly, uses a lot of power, and as in most electronics, battery life is an issue. The creation of electronics that use less power and/or that save and harvest or store their own power will help this. A footprint is another challenge–how to make the electronics even smaller still.

Brewer’s Herleb said, “We will be focusing on new materials to increase sustainability and reduce cost. The goal is low-power, flexible devices developed using flexible inks, and hi-tech screen printing that can place these sensors in any arrangement imaginable.”

MSWTEch’s Mildner is again chairing LOPEC, the International Exhibition and Conference for the Printed Electronics Industry to be held at the Munich Convention Center March 13-15. CuteCircuit, a London-based pioneer in electronic fashion, is scheduled to present some of its products at the conference. The firm has created an evening gown with 10,000 LEDs that can show animated images on the fabric and its Soundshirt that helps deaf people experience concerts by turning sounds into vibrations.

Article Courtesy: Sourcing Journal