The use of Waste Heat contributes largely to sustainable energy supply. Scientists of Karlsruhe Institute of Technology (KIT) and Tōhoku University in Japan have now come much closer to their goal of converting waste heat into electrical power at small temperature differences. As reported in Joule, electrical power per footprint of thermomagnetic generators based on Heusler alloy films has been increased by a factor of 3.4.

Many technical processes only use part of the energy consumed. The remaining fraction leaves the system in the form of waste heat. Frequently, this heat is released into the environment unused. However, it can also be used for heat supply or power generation. The higher the temperature of the waste heat is, the easier and cheaper is its reuse. Thermoelectric generators can use waste heat of low temperature for direct conversion into electrical power. Thermoelectric materials used so far, however, have been expensive and sometimes even toxic. Moreover, thermoelectric generators require large temperature differences for reaching efficiencies of just a few percent.

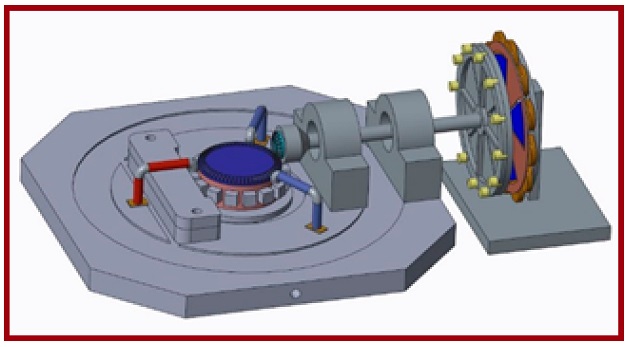

Thermomagnetic generators represent a promising alternative. They are based on alloys, whose magnetic properties are highly temperature-dependent. Alternating magnetization induces an electrical voltage in a coil applied. Researchers presented first concepts of thermomagnetic generators in the 19th century already. Since then, research has covered a variety of materials. Electrical power, however, has left a lot to be desired.

Scientists of KIT’s Institute of Microstructure Technology (IMT) and Tōhoku University in Japan have now succeeded in largely increasing the electrical power per footprint of thermomagnetic generators. “Based on the results of our work, thermomagnetic generators are now competitive with established thermoelectric generators for the first time. With this, we have come to a lot closer to the goal of converting waste heat into electrical power at small temperature differences,” says Professor Manfred Kohl, Head of the Smart Materials and Devices Group of IMT.