A thermocouple is a temperature-sensing device used to measure temperatures in a wide range of applications. It operates on the principle of the Seebeck effect, which is the phenomenon where a voltage is generated at the junction of two dissimilar metals when there is a temperature difference between the junction and the free ends of the metals.

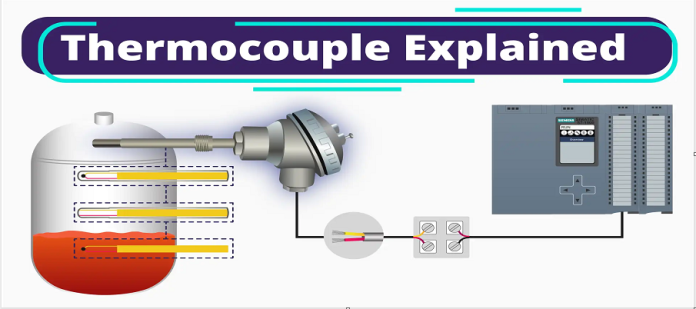

The basic construction of a thermocouple includes two different metal wires joined together at the ends to form a loop. One end is known as the “hot junction”, where the temperature to be measured is applied, while the other end is referred to as the “cold junction”, which typically remains at a reference temperature.

When there is a temperature difference between the hot and cold junctions, a voltage is produced at the junction due to the Seebeck effect. This voltage is proportional to the temperature difference and can be measured using a voltmeter.

Proper calibration, maintenance, and usage are essential to ensure accurate and reliable temperature measurements. Regular calibration checks can help verify the accuracy of the thermocouple over time and maintain its performance in critical applications.

Over time, scientists and engineers have standardized certain metal combinations to create different types of thermocouples, each with its unique characteristics and temperature range. These standardized combinations ensure consistency and accuracy in temperature measurements across various applications.

It is essential to choose the appropriate thermocouple type for a specific application to ensure accurate and reliable temperature readings. The standardized metal combinations and defined thermocouple types help achieve consistency and comparability across different devices and industries.

Thermocouple- Working Principle

The Seebeck effect is a phenomenon where a voltage is generated at the junction of two dissimilar conductive materials when there is a temperature difference between the junction and the ends of the materials. This voltage is proportional to the temperature difference between the two ends of the thermocouple.

In a thermocouple, when the two dissimilar metal wires are joined at the ends to form a loop, and one of the junctions (hot junction) is subjected to a different temperature than the other junction (cold junction), a continuous flow of electric current is established in the thermoelectric circuit due to the voltage produced by the Seebeck effect.

The net open voltage, or the Seebeck voltage, that results from this temperature difference is directly related to the junction temperature and the composition of the two metals used in the thermocouple. Each thermocouple type has its unique combination of metals, and this determines its sensitivity, temperature range, and accuracy.

By measuring the voltage generated by the thermocouple, it is possible to correlate it back to the temperature difference between the hot and cold junctions. Since the cold junction temperature can often be assumed or measured separately, the voltage output of the thermocouple can be used to accurately determine the temperature at the hot junction.

Types of Thermocouple

The thermocouple is defined by the hot junction formed between two metals exhibiting different properties. The two dissimilar metals used to manufacture a thermocouple are referred to as the positive and negative legs. The combination of metals chosen for these legs determines the type of thermocouple.

Primarily, thermocouples are of 8 types-

- B-Type

Type-B thermocouple is made from the combination of Platinum (6% Rhodium) and Platinum (30% Rhodium). They exhibit a temperature range between 1370 degree Celsius to 1700 degree Celsius. They are commonly used in industries and processes that involve extremely high temperatures, such as in certain types of furnaces, kilns, and high-temperature ovens. Their ability to withstand and accurately measure extreme temperatures makes them valuable in these specialized applications. One of the main advantages of Type B thermocouples is their stability and resistance to drift over time. They are less susceptible to grain growth, which can affect the accuracy of temperature measurements

- E-Type

Type-E thermocouples are composed of two dissimilar alloys: Chromel (an alloy of nickel and chromium), and Constantan (an alloy of copper and nickel). They are designed to measure temperatures in the range of 0 degrees Celsius to 870 degrees Celsius. They are known for their excellent stability and resistance to oxidation in various atmospheres. They can be used in inert environments and are suitable for many industrial applications where precise temperature measurements are required. However, they are sensitive to sulphur-containing atmospheres and may be affected by the presence of sulphurous environments. In such cases, they need supervision and protection to prevent potential inaccuracies caused by the interaction with sulphur compounds. This type is commonly used in industries including power plants, petrochemical, and food processing, as well as research and scientific applications.

- J-Type

Type J thermocouples are made by combining two different metals: Iron and Constantan. They are designed to measure temperatures in the range of 0 degrees Celsius to 760 degrees Celsius. They are well-suited for vacuum or inert environments due to their stability and resistance to oxidation in such conditions. They are commonly used in many industrial and scientific applications, including in research labs, food processing, and some low to medium-temperature industrial processes. However, it is important to note that the lifespan of Type J thermocouples can be reduced when exposed to extremely high temperatures. Type J thermocouples offer good accuracy and sensitivity in their operating temperature range, but they may not be ideal for extremely high-temperature environments where other thermocouples types with higher temperature ranges, such as Type K or Type N.

- K-Type

Type K thermocouples are composed of two different alloys: Chromel – for the positive leg and Alumel – for the negative leg. They are one of the most common thermocouple types. They have a temperature range that spans from approximately 0 degrees Celsius to 1260 degrees Celsius. They are well suited for use in both oxidizing and neutral environments, making them versatile and applicable in various industries. One essential characteristic of Type K thermocouples is that they can generate an EMF (electromotive force) variation below 982 degrees Celsius. Hence, they are not used in highly reducing or inert environments at temperatures below this threshold, as it may lead to inaccurate readings.

- N-Type

Type-N thermocouple is made by combining Nicrosil (an alloy of nickel, chromium, and silicon) for the positive leg and Nisil (an alloy of nickel and silicon) for the negative leg. They are specifically designed to measure temperatures in the range of 650 degrees Celsius to 1260 degrees Celsius. One major advantage of Type N thermocouples is their ability to offer high resistance to degradation due to factors like “green rot” and hysteresis. Green rot refers to a condition in certain thermocouples where the materials undergo degradation and result in measurement inaccuracies over time. Type N thermocouples are less susceptible to this issue, contributing to their stability and reliability in temperature measurements.

- R-Type

Type-R thermocouples are made by combining Platinum (13% Rhodium) for the positive leg and pure platinum for the negative leg. They are designed to measure temperatures in the range of 870 degrees Celsius to 1450 degrees Celsius. They are known for their high accuracy and stability in high-temperature environments. The addition of Rhodium in the positive leg enhances their temperature range and performance. They are majorly used in critical industrial processes, including in sulphur recovery units, where precise temperature measurements are crucial for safety and efficiency.

- S-Type

Type S thermocouples are made by combining Platinum (10% Rhodium) for the positive leg and pure Platinum for the negative leg. They are specifically designed to measure temperatures in the range of 980 degrees Celsius to 1450 degrees Celsius. This temperature range makes them suitable for a variety of high-temperature applications. The addition of Rhodium in the positive leg enhances the thermocouple’s performance and increases its temperature capability compared to type B and Type r thermocouples.

- T-Type

This type of thermocouple is composed of Copper for the positive leg and Constantan for the negative leg. They are specifically designed to measure temperatures in the range of -200 degrees Celsius to 370 degrees Celsius. They are known for their wide temperature range and excellent performance in low to medium-temperature applications. They are commonly used in various industries and scientific settings. One major advantage of Type T thermocouples is their ability to operate in various atmospheric conditions. They can be used in oxidizing, inert, and vacuum environments. Also, they do not corrode in moist atmospheres, which makes them suitable for applications where moisture or humidity is present.

Application Areas of Thermocouples

Thermocouples are widely used as temperature-sensing devices due to their robustness, reliability, versatility, and wide temperature range capabilities. They find numerous applications across various industries and scientific fields. Some significant application areas of thermocouples include-

- Industrial Processes – Thermocouples are extensively used in industries like petrochemical, chemical, metalworking, glass manufacturing, and cement production for temperature monitoring and process control. They help ensure that the processes run at the desired temperatures and avoid any potential damage or safety risks.

- HVAC Systems – Heating, ventilation, and air conditioning systems use thermocouples for temperature regulation. They help control heating and cooling systems to maintain a comfortable and consistent indoor climate.

- Food Industry – Thermocouples monitor and control temperatures to ensure food safety during storage, processing, and transportation.

- Power Plants – In power generation facilities, thermocouples are used to monitor the temperature of the steam and other fluids, ensuring the efficient operation of turbines and boilers.

- Automotive Industry – Thermocouples are employed in automotive engines to measure exhaust gas temperature and optimize fuel efficiency and emissions.

- Aerospace – In aircraft and space exploration, thermocouples are used to monitor critical components’ temperatures and ensure safe operation.

- Research and Laboratories – Thermocouples are commonly used in scientific research, laboratories, and experimental setups for precise temperature measurements.

- Medical applications– In medical devices and equipment, thermocouples are used for temperature monitoring in incubators, sterilizers, and diagnostic instruments.

- Environmental monitoring – Thermocouples are employed in weather stations and environmental monitoring equipment to measure air and soil temperatures.

- Furnaces and ovens – Thermocouples are essential for temperature control and safety in high-temperature furnaces and industrial ovens.

- Energy-efficient systems – Thermocouples are used in various energy-efficient applications, such as solar water heaters and geothermal systems.

- Automotive testing – In automotive testing and development, thermocouples are used to measure temperature profiles and performance of various vehicle components.

These applications are just a few areas, thermocouples are used in many other diverse ways. Their wide range of temperature capabilities, durability, and cost-effectiveness make them one of the most popular temperature sensors across various industries and scientific domains.