A research team has conducted a review of recent advances in perovskite photovoltaic modules. Perovskite solar cells hold great promise for the next generation of photovoltaic technology. With this promising technology comes a need for high-quality perovskite films for large-area photovoltaic modules. The team’s study aids researchers who are working toward the further commercialization of perovskite photovoltaic modules.

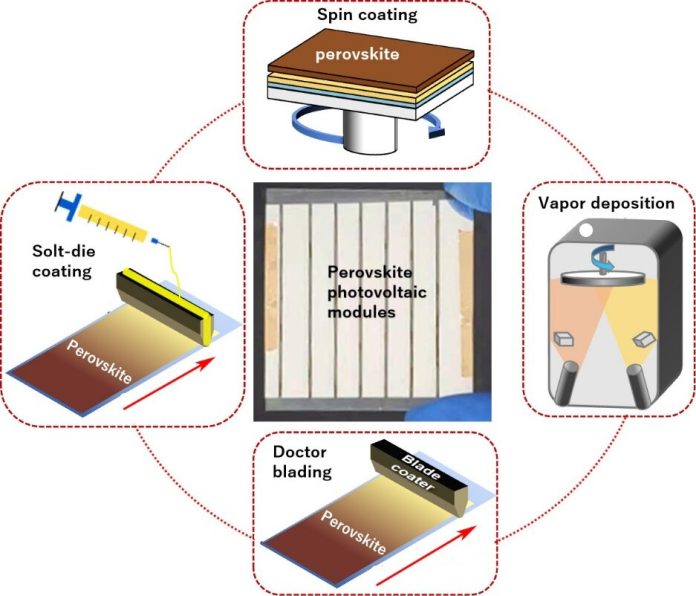

In the study, the team examined and summarized the recent advances in perovskite photovoltaic modules, focusing their attention on the coating methods used on these modules. These methods included spin coating, doctor blading, slot-die coating, spray coating, inkjet printing, soft-cover deposition, and vapor deposition. They also examined the growth regulation of high-quality and large-area perovskite films. Their study encompasses future development directions and prospects for perovskite photovoltaic modules.

The perovskite solar cells offer optoelectrical properties that are very useful in photovoltaic applications. Perovskite solar cells are less expensive and can be fabricated more simply than the silicon solar cells currently in use. Because of this, these perovskite solar cells are attracting attention from both academia and industry. In particular, the perovskite solar cells are high efficiency and can be manufactured through low-cost processes.

Perovskite solar cells have achieved a certified laboratory-scale power conversion efficiency of 25.7 percent. Because of their high power conversion efficiency and low cost, perovskite solar cells hold great promise for future commercialization. But while these high-efficiency perovskite solar cells can be fabricated with an area of fewer than 0.1 cm2, researchers are experiencing challenges in successfully enlarging the perovskite films for bigger photovoltaic modules.

Researchers find it difficult to expand the high-quality films from small-area to large-area modules. The high power conversion efficiency that can be achieved with small-area perovskite solar cells drops significantly when they are used in larger perovskite photovoltaic modules. Until this hurdle can be overcome, it is difficult to fabricate these perovskite solar cells for large-area commercial use.

“For manufacturing large-area perovskite photovoltaic modules towards industrialization, lots of issues need to be solved, such as the relatively low efficiency of large-area perovskite photovoltaic modules, the preparation of large-area and high-quality perovskite films, and the design of interconnected sub-cells to composite modules,” said Liang Chu, professor at Hangzhou Dianzi University. The first step is to be able to deposit large-area perovskite films with high uniformity and reproducibility.

The processes for depositing large-area perovskite films are varied without a standardized industrial scale. These coating methods are important because the thickness, crystallinity, surface roughness, and compactness of perovskite films directly affect their absorption, charge generation and separation, and device performance. The researcher team studied and analyzed the various coating methods, identifying their limitations and exploring the potential perovskite photovoltaic modules might hold for future commercial applications.

Looking toward future commercialization, the research team notes several development directions. They suggest that researchers continue to develop the coating methods for the large-area high-quality perovskite films, with the perovskite compositions further optimized to enhance the efficient perovskite photovoltaic modules.

They also suggest that the buried and surface layers should be simultaneously modified to passivate the perovskite defects in perovskite photovoltaic modules. These interface layers solve the corrosion reaction issue. The team’s last recommendation is that researchers should consider the stability strategies, which have been widely used in small-area perovskite solar cells. “These strategies could greatly improve the stability of large-area perovskite photovoltaic modules,” said Chu.