With the passage of time and various advancements in technology, the process of assembly and manufacturing has changed phenomenally. The innovative new methods used in various parts of electronic assembly and manufacturing line has very effectively reduced the consumption in manufacturing and has increased productivity and quality throughout. There are so many software now a days used in all field of electronic manufacturing.

These software not only reduce time but do give the most precise and accurate outputs in the market for industrial needs. The Surface Mounting Technology in today’s industry has

evolved much and is improving day by day. The rapid use of software for the assembly purpose has made this sector of manufacturing efficient and smooth.

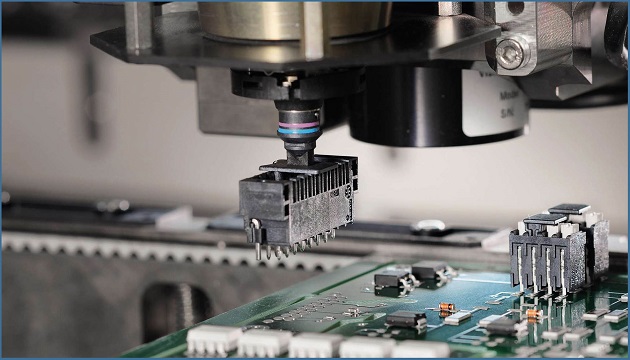

Today in the PCB assembly process, most of the components on a board are placed automatically. Today, printed circuit boards are normally developed to reduce this to an absolute minimum, even to the extent of altering the design to use components that can be placed automatically. In addition to this, component manufacturers have developed some specialised surface mount versions of components that enable virtually complete automated nassembly for most boards.

Market Facet and Software used

Since the last few years, India has seen an unprecedented upward growth across the board. In the electronics sector, India continues to be a laggard and a largely consumer nation. Assessing by the pulse of the market, the largest segment to boost the SMT industry would be pick and place machines since they have an application across all major verticals like consumer and automotive. At this juncture, it should be noted that along with the right hardware, it is important to have the right software as well.

In today’s world, there is no room for errors and the same will have to apply on the SMT equipment. The pulse of the market for the SMT industry seems to clear some air. India boasts of a big and diversified population where different people have different requirements. The Indian SMT manufacturing equipment market in India is also bound to grow along with the electronics manufacturing sector in the country. The Indian electronics market is one of the fastest growing in the world and is anticipated to reach US$ 400 billion in 2022. This burgeoning market presents an attractive opportunity to suppliers of SMT manufacturing equipment.

Due to the majority of electronic products specifying surface mount components, the bulk of assembly work is performed within Surface Mount Technology. The SMT today is equipped with the latest manufacturing tools and is prevalent in the industry. Electronics manufacturing using surface-mount technology simply means that electronic components are assembled with automated machines that place components on the surface of a board. In contrast to conventional through-hole technology processes, SMT components are placed directly on the surface of a PCB instead of being soldered to a wire lead. When it comes to electronic assembly, SMT is the most frequently used process in the industry.

Some of the predominant software used in the industry are mentioned below:

Reflow Oven Linux Base Control Software

Reflow Linux based software packages from EMS Technologies Pvt Ltd allow simulation, control, and documentation for reflow and curing ovens and processes. This will control and regulates oven zone temperatures, feed rate, and conveyor width. Depending on the oven model, EMST Reflow can automatically set up an oven and start production when ready. Status messages are displayed graphically and both incoming/ outgoing boards are monitored. Software feature/access can be given to specific individuals and all operator actions are nlogged allowing only those with appropriate authorization to create or modify soldering programs or SMEMA interface settings. This Reflow Oven Controller relies on an Arduino Pro Micro, which is similar to the Leonardo and easily obtainable actually more like a motherboard.

V2 Software

In this software, first PCB mark points are set and function enabled mark test will be applied to each PCB in a panel before placement. It offers two modes of mark detection based on panel or single PCB. Mark points per panel or single PCB means a pair of points in opposite edges to align the Placement data. It’s important to find the mark point position on first master PCB using the vision functions and take over the given position to PCB settings mark point position.

V-ONE

The software uses the height map to compensate for any inconsistencies and irregularities on the surface and makes micro adjustments in real time to ensure a perfect print. V-ONE came nin handy as the digital dashboard and AI analytics for smart manufacturing. It offers data- driven decisions in the manufacturing process by allowing stakeholders to remote, visualize, monitor, control and implement condition-based alerts with the ticketing feature to reduce downtime and increase throughput.

Intelligent Factory from Yamaha

It generates streamlined PCB data to shorten production time. The common part allocator function for multiple products and converts data generated by CAD and other equipment into data. The tool optimizes multiple boards by automated grouping, setup and changeovers into common, collective shape. It efficiently slashes man-hours needed for production setups to cut the overall production time. Shortens time for creating PCB data and boosts quality.

SMTrue Run Optimize Software

It provides an off-line tool for setting up new SMT assembly programs or modifying existing SMT assembly programs, saving time. The SMTrue Run Optimize Software is the same software used on automated pick and place machine which has the capability for setting up new SMT assembly programs or modifying existing SMT assembly programs. It is efficient in increasing throughput by programming as pick and place machine runs. It also provides off-line job and feeder set-up, programming, optimization, and management for automated pick and place machine.

Unisoft Pronto PLACE Software

In minutes, Unisoft ProntoPLACE software translates files into real reference designators. This data is then used by Process Engineers to program their SMT and Automatic Assembly Equipment. ProntoPLACE programs popular newer and older surface mount (SMT) placement, through-hole (THT) insertion and glue dispensing machines. ProntoPLACE also creates process sheets for assembly aids and to document assembly process. It instantly receives a report containing device and package type counts with quotation and cost estimations.

Mirae Machine Software

It provides an easy to use graphical user interface and efficient programming functions to manage high volume and complex production. This package consists of the machine control software, real-time vision software, GUI software and optimization software. This software packages are installed on the machine to enable an independent programming and production on a machine. Mirae machine software is not only easy to use, but also designed to maximize flexibility and mass production. Software works on MS Windows environment.

Vayopro- SMT Expert

VayoPro-SMT Expert is an essential tool for intelligent & fast programming to new product introduction. It fasts conversion data and intelligently corrects parts angle/rotation. It minimizes human interfere error, reduces programming & fine-tuning cycle, leverages machine utilization and save labour cost.

Conclusion

The SMT placement equipment market is experiencing significant new growth opportunities within Central and Eastern Europe for consumer electronics, telecom and automotive electronics manufacturing. The region is also attractive for low-cost manufacturing locations for the top global providers, which is further expanding demand for SMT production equipment. The Asia-Pacific region remains the largest generator of SMT revenues and leads demand for high-speed SMT placement equipment.

SMT placement manufacturers are improving machine flexibility with larger feeder capacities and multi-functional placement heads day by day. As the demand for high-mix and low to medium volume manufacturing environments continues to increase. Machine flexibility and placement speed, for greater throughput.

The wider adoption of high-performance software will allow SMT placement equipment manufacturers to keep up with the increasing technological demands of the electronics industry. Encoder technology employed within SMT placement equipment is directly responsible for improving placement accuracy and repeatability as well as increasing the speed of each axis, thereby boosting machine throughput to higher levels.

By: Mannu Mathew | Sub Editor | ELE Times