In this article, we will discuss specific analog features integrated into motor driver ICs that help address these design challenges.

Mitigating EMI

EMI mitigation is achieved using features and solutions both at IC level and at printed circuit-board (PCB) level. One key method to mitigate to EMI is control of pulse width modulation (PWM) edge rates. Gate driver products such as DRV8705-Q1, DRV8706-Q1, DRV8714-Q1 and DRV8718-Q1 gate drivers for brushed DC (BDC) motors, and three-phase DRV8343-Q1 for brushless DC (BLDC) motors all integrate smart gate-drive technology, which is specifically used to control the PWM edge slew rates. Furthermore, these devices offer the ability to select slew rate that best mitigates EMI. Another common technique used to reduce EMI is dithering the main clock frequency. DRV10983-Q1 three-phase BLDC motor driver with integrated MOSFETs also integrates dithering of the main clock frequency, thus reducing the amplitude by spreading the peak across the spectrum

Managing thermals

Motor operating and stall currents have a wide range of values based on the load being driven. For high current loads, gate-driver products give you the choice of implementing your designs using discrete MOSFETs. Electronic control module designers can optimize layout and thus achieve optimal thermal management. For low load current loads, devices such as DRV8873-Q1, DRV8874-Q1 and DRV8876-Q1 with integrated H-bridge MOSFETs can be used to drive the loads while achieving optimal thermal management. Moreover, for low current loads driven by three-phase BLDC motors, DRV10983-Q1with integrated MOSFETs can be used. Note that DRV10983-Q1 also integrates the commutation algorithm, enabling single-chip solution to drive the motor.

Current sensing

The current in the motor is measured to detect circuit and motor faults, and to infer motor position using ripple counting. All TI BDC and BLDC motor- and gate-driver products integrate current-sense amplifiers to amplify the voltage across the resistor. Furthermore, the DRV8106-Q1, DRV8706-Q1, DRV8714-Q1 and DRV8718-Q1 offer an in-line current-sense amplifier. Using in-line current sense measurements, the direction of motor rotation can also be determined.

Windows are traditionally driven using BDC motors. However, system designers are investigating the use of BLDC motors to drive the window because BLDC motors are quieter. In addition, BLDC motors are also being considered for rotating the seat base in autonomous vehicles. The 3-phase smart gate driver DRV8343-Q1 which integrates the current sense function can be used in these applications.

Power-off braking

With MOSFET solutions, a motor can be rotated freely when power to the motor is turned off. In such cases, moving the load manually, for example, opening or closing a power trunk manually, could result in large back EMF which could damage the electronics. The DRV8714-Q1 and DRV8718-Q1, targeted for trunk control module applications, integrate a power-off braking feature, which measures the voltage being generated and applies electronic brakes to the motor. This feature stops the motor from rotating, which in turn stops the generation of current.

Diagnostics and protection

Detecting circuit faults and protecting the systems against these faults is an important requirement when controlling motors. The BDC and BLDC gate drivers integrate diagnostic circuits to detect open and short circuits. In addition, we also provide failure-mode distribution and pin failure mode analysis information for some ICs to aid functional safety design when needed.

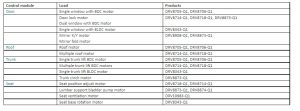

Implementing control modules in body applications

Table 1 maps the products to the motors used in these applications.

Courtesy- Texas Instruments