Without sensors, there would be no Internet of Things (IoT). They measure and record temperature, brightness, movement and many other parameters and transfer the data to the smart control devices. Sensors however need power. Although their power consumption is generally very low, they cannot work without it. Making sure that battery-operated sensors keep running for many years without any maintenance is quite a difficult task. This article describes how the service life of batteries can be significantly extended and how three times more current can be harvested from a 4-20mA loop by making use of innovative solutions.

RECOM Power GmbH

With the arrival of Industry 4.0, cyber-physical systems, the Internet of Things and cloud computing have found their way into modern factories. Operating as integrated communication networks, cyber-physical systems take decisions and act, while communicating in real-time with other systems as well as with humans. One of the main reasons for the rapid technological progress over the last few years is the drop in price of sensors of all types. Only ten years ago, sensor technology was the preserve of highly specialised applications. Today, sensors are a mass product. This development has made it possible to integrate more and more devices into networks where they combine, process and exchange ever larger volumes of data. However, every single sensor in such a network must be supplied with power – be it through a central power supply or a battery.

The myth of the 3V coin battery

Many IoT and Industry 4.0 applications run with 3V coin batteries, which are not only cheap but also very reliable. Such batteries need however to be changed quite frequently. A fully charged CR2032 coin battery supplies approximately 3.2V. After only a few operating hours, the voltage drops however to below 3V, which might not be sufficient for certain wireless modules (WLAN, Bluetooth, LoRaWAN, etc.). As a result, transmission can become unreliable or the signalling range might suddenly be limited.

Extending the service life of batteries by using switching regulators

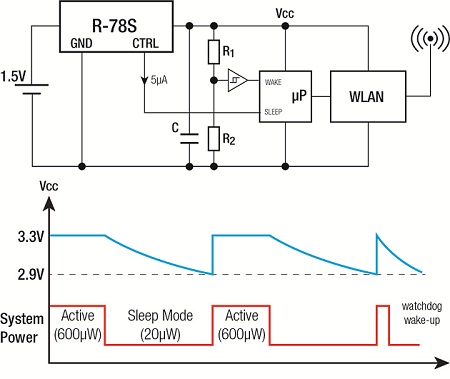

The R-78S boost switching regulator from RECOM (figure 1) has been specially developed for battery-powered IoT devices. The plug & play module provides a stable output of 3.3V from input voltages of as little as 0.65VDC to 3.15VDC, squeezing the last bit of energy from the battery cell. The R-78S thus enables users to run microprocessors, WLAN/Bluetooth modules and IoT systems with a single 1.5V battery or cell, which has a much longer service life than a conventional coin battery.

Figure 2 shows a typical application of the R-78S in a wireless module. The circuit is only activated for brief periods to send data. During these short times, the entire circuit consumes around 600µW. When not sending data, the circuit is in sleep mode. During these times, the R-78S is powered by a buffer capacitor and consumes only 7µA. If the capacitor charge drops below a certain limit, the circuit is briefly activated for recharging. This technology guarantees reliable, maintenance-free operation for periods of 10 years and more. As converters are cheap, the extra investment pays for itself in no time thanks to much lower battery and maintenance costs.

Solutions for hard-wired systems

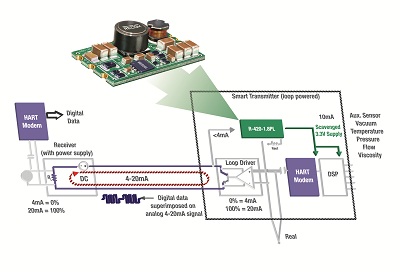

The 4-20mA loop is a well-established standard in process and control technology. Seventy years after its conception, the technology is still widely used and will continue to play a major role in many applications. 4-20mA loops are ideal for use in harsh industrial environments, as their current signals are not susceptible to interference. The loops are based on a simple two-wire technology where signals are transmitted in the form of defined currents. In all applications, 4mA corresponds to 0% and 20mA corresponds to 100%. This makes the system intrinsically safe, as there must always be a current of at least 4mA. Wire breaks or sensor failures are detected instantly: if there is no current, there is a problem. 4-20mA loops cater for signal transfer over long distances whereby the signal can be tapped at any point along the line. Modern digital technology has given 4-20mA loops a welcome boost. In the latest 4-20mA loop systems, data from multiple sensors is processed and combined by means of DSP and then sent along a single analog line in the form of a frequency-modulated burst of pulses. This requires two HART (Highway Addressable Remote Transducer) modems that modulate the digital data packets at the transmitter into analog signal and then demodulate the data again at the receiver (see figure 3). This approach allows for the integration of additional sensors without having to install more loop cables, which is one of the main reasons why HART is now the most popular data protocol in the process industry. HART technology is thus playing a major role in keeping 4-20mA loop technology alive.

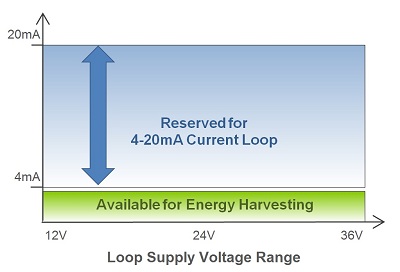

Current interface for the supply of sensors

In 4-20mA loops, the current below the measuring threshold (<4mA) can be used to power sensors and other devices. While such low currents are normally sufficient to supply one analog sensor, they are not adequate for intelligent sensors (with DSP and/or display), of the supply of multiple sensors. If there is a power source available nearby, there is obviously not a problem. For components installed further away from a power supply, the cost of laying power cables can however be considerable. Despite being highly efficient under full load, conventional switching regulator ICs are not a solution to this problem, as they exceed the 4mA threshold even at low loads. Their extremely low idle current in sleep mode is of no help here, as the output voltage drops to zero. Also not ideal are linear regulators. While their idle current of around 0.5mA is within the “green range” of the 4-20mA loop, their low efficiency means that they can generate only a third of the power that can be harvested with a switching regulator.

The new R420-1.8/PL switching regulator from RECOM (figure 5) is a particularly smart solution to overcome these problems. Thanks to its innovative topology, the idle current of the R420-1.8/PL has been reduced to 0.5mA, while the full rated voltage is available at the output. Let’s look at a concrete example: with 24VDC and <3.5mA at the input, we get 3.3V and 10mA at the output, which is sufficient to power a micro-controller and a HART modem as well as multiple sensors without diminishing the functionality of the loop or the measuring accuracy of the system in any way. Another advantage of the new switching regulator lies in the fact that it can be easily combined with a resistor to achieve output voltages between 1.8V and 5V.

Conclusion

As the Internet of Things is really an internet of sensors, it depends on innovative power supply solutions. RECOM offers intelligent components that help safe battery power, for instance with the R78-S boost switching regulator. These regulators squeeze the last bit of energy from the battery, so that applications can be run for more than a decade without any problems and no need for servicing. At the same time, tried and tested technologies such as the 4-20mA loop are enjoying increased popularity – thanks to digitisation. Innovative switching regulators such as RECOM’s R420, which provides three times more power at the output than a conventional linear regulator, make sure that a technology that served us well in the past will continue to do so in the future.