Scientists from the Skoltech Center for Design, Manufacturing and Materials (CDMM) and the Institute for Metals Superplasticity Problems (IMSP RAS) have studied the fatigue behavior of additive-manufactured high-entropy alloys (HEA). The research was published in the Journal of Alloys and Compounds.

Conventional 20th-century materials that are extensively used in industries and mechanical engineering have reached their performance limit. Nowadays, alloying is commonly used to improve the alloys’ mechanical performance and increase their operating temperature. An alternative to alloying, HEAs containing equal atomic fractions of their constituent elements were first obtained in 2004. Since then, various publications have offered ample evidence of excellent mechanical performance of HEAs over a broad temperature range. Most of the characteristics were demonstrated for HEAs manufactured by traditional metallurgy techniques.

“Looking at the properties of additive-manufactured HEAs, we discovered that previous research was focused on the static characteristics of printed HEAs. However, from the standpoint of practical applications, it is essential to study the properties of HEAs under cyclic loads,” explains Stanislav Evlashin, a leading research scientist at Skoltech.

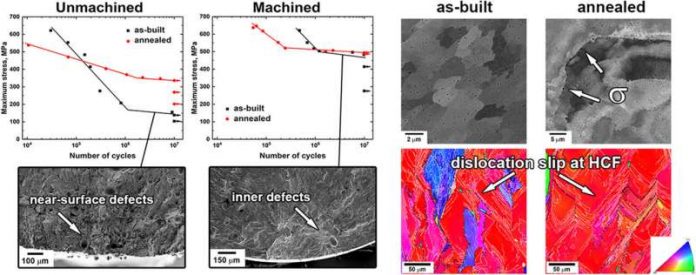

In their recent work, the team studied the fatigue properties of CrFeCoNi, an alloy produced by the Laser-Powder Bed Fusion (L-PBF) technique, building on previous HEA research.

“In our new study, we have shown that the annealing of printed samples reduces residual stress, improves plasticity and slightly decreases yield strength, We have demonstrated that machining removes surface defects and extends the fatigue life,” says Yulia Kuzminova, a Ph.D. student at CDMM.