The semiconductor shortage, which was expected to ease by mid-2022, is likely to get worse. As Russia and Ukraine are both suppliers of components used in semiconductor manufacturing, Russia attacking Ukraine will further stress the industry globally — and fears are that it can result in manufacturing constraints leading to supply shortages and semiconductor price hikes.

“Just like Taiwan, both Ukraine and Russia also play a pivotal role in the global semiconductor supply chains. Ukraine is a significantly important source and supplier of raw materials, including, for instance, semiconductor-grade neon used in semiconductor manufacturing. Similarly, Russia is a key source of palladium used in many memory and sensor chips. In fact, it accounts for 45 per cent of the global supply. As such, the trickle-down effect of the war could potentially impact chip capacity and consequently, spike chip prices,” Prabhu Ram, Head – Industry Intelligence Group, CyberMedia Research

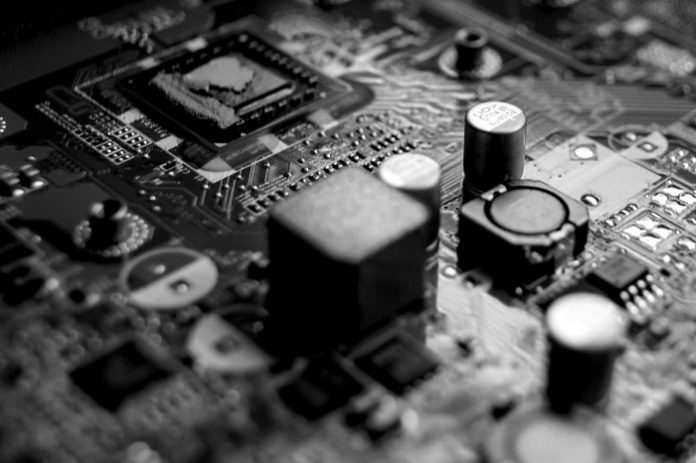

Semiconductors, that power everything electronic on earth and also in space, have a complex ecosystem of chip manufacturing. And chip manufacturing is a difficult and complex process. The global semiconductor industry is interdependent, and no nation in the world has managed to master the ecosystem as yet.

Industry experts explain, companies like Taiwan’s TSMC, China’s SMIC or South Korean Samsung Semiconductor Inc. are the contract chipmakers that share wafer specifications with fabless companies and IDMs, post which these companies send their design IPs to be printed on the wafers.

Wafers are then turned into semiconductors using high-precision processes and machinery sourced from companies such as Netherland-based ASML, Japan-based Tokyo Electron and Applied Materials of the US. When it comes to components, Russia is the leading producer of palladium. Palladium is essential for memory and sensor chips. It also produces several other key raw materials for computer chips, including the rare–earth metal, scandium.

On the other hand, Ukraine is a leading exporter of neon gas. It is a highly purified gas that is used for the most important process – etching circuit designs into silicon wafers to create chips.

Navkendar Singh, Research Director at IDC India told, “Russia and Ukraine are important in the supply chain of components for semiconductor manufacturing. They produce important gases and rare earth metals, which are used in the lithography.”

Using lithography, etching and deposition, layers after layers of transistors are laid out on the silicon, followed by an interconnected network of copper wires, which could involve anywhere over 300 to 700 steps.

Once these wafers are printed, the chips are shipped across testing facilities such as Amkor Technology Philippines, Inc. in the Philippines and Unisem Group in Malaysia for testing and packing.

Here chips on the wafer that are not functioning are discarded and the ones operational are further sorted, cut, and packaged. Post packaging, there is another round of testing, and the final chips are shipped back to the companies such as Intel, Micron, MediaTek, Saankhya Labs across the world, who then ship them to their clients (OEMs) who put them in the final product.

The industry that was worth about $440 billion in 2020, as per research firm Statista, is estimated to grow to about $550 billion this year, on its way to crossing $600 billion next year.

Dr Satya Gupta, President VLSI Society of India, Advisor, IESA, says, “Semiconductor Supply chain is a complex Eco-System involving companies from different countries and continents for raw material, equipment, wafer manufacturing, packaging, fabless companies, distributors and finally electronics products as customers. Any small disruption in any part of this supply chain creates a bubble in this complex supply chain which affects everybody.

This is similar to a small accident on the Highway which can create a bubble and affect the traffic for many hours. Events like war have a significant impact on this ecosystem. Everybody fears an escalation of the situation and to protect their businesses start ordering semiconductor chips in advance stressing the supply side of the ecosystem. Semiconductor ecosystem is just recovering from the shortage of chips during the pandemic and this war will further stress the system leading to a shortage of chips, long lead times and escalated prices and impact on all business verticals.”