Temperature sensors are critical components in a variety of industries, from manufacturing and automotive to healthcare and environmental monitoring. Among the most common temperature-sensing devices are Resistance Temperature Detectors (RTDs), thermocouples, and thermistors. Each of these sensors has unique characteristics, advantages, and limitations, making them suitable for different applications. This article provides a detailed comparison to help you choose the right sensor for your needs.

- Resistance Temperature Detectors (RTDs)

RTDs measure temperature by correlating the resistance of a material (usually platinum) to temperature. Platinum is preferred because of its stability and linear resistance-temperature relationship.

Key Features of RTDs:

- Accuracy: RTDs deliver exceptional precision, typically within ±0.1°C.

- Stability: They provide outstanding consistency and reliable performance over long durations.

- Temperature Range: Commonly operate effectively between -200°C and 600°C.

- Linearity: RTDs exhibit a near-linear relationship between resistance and temperature, simplifying data interpretation.

Advantages:

- Highly precise and reliable.

- Extended operational life with negligible performance degradation over time.

- Suitable for industrial and laboratory settings.

Limitations:

- Expensive compared to thermocouples and thermistors.

- Fragile and sensitive to physical shocks and vibrations.

- Requires external circuitry for resistance measurement.

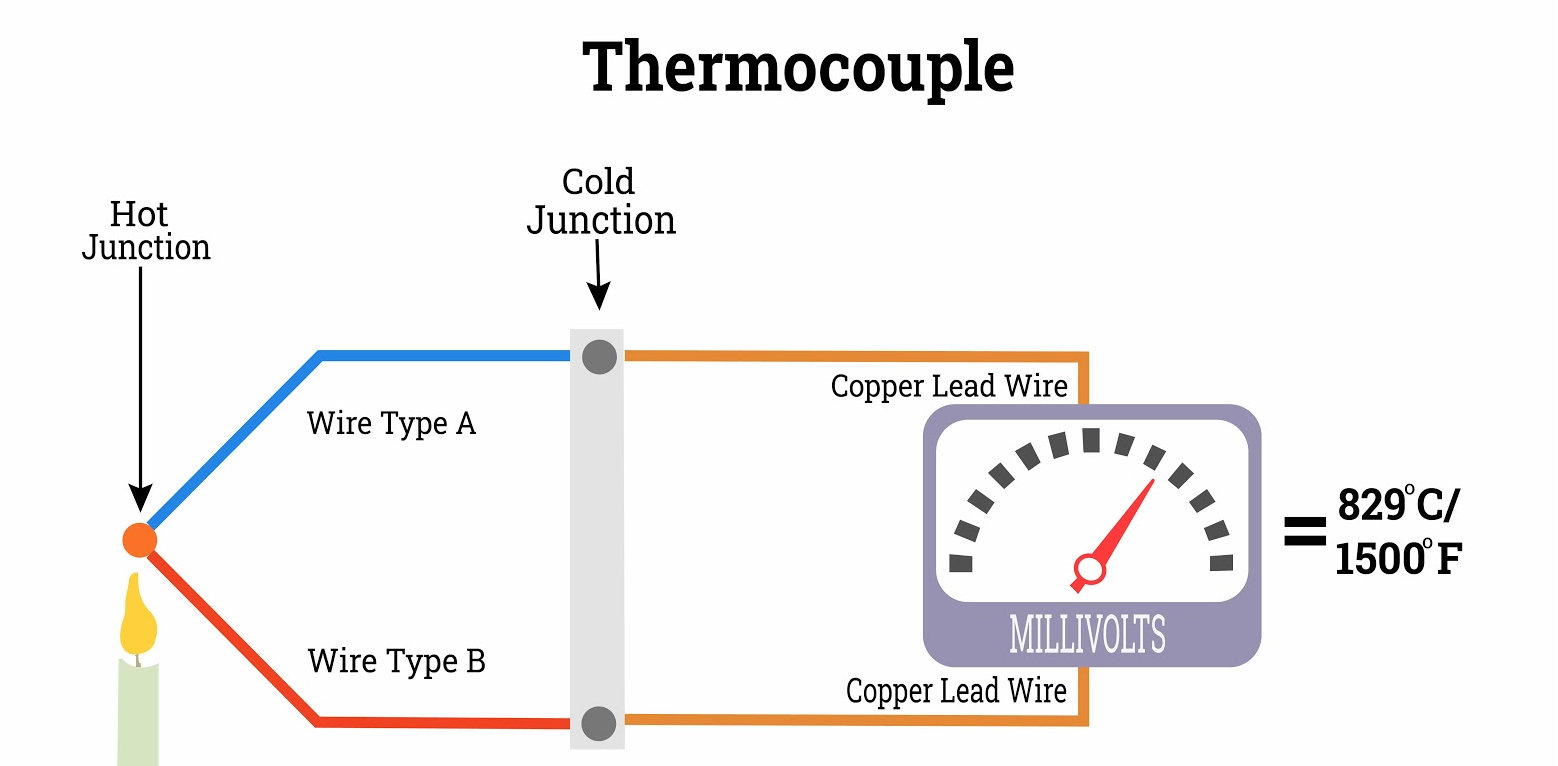

- Thermocouples

Thermocouples generate an electrical voltage that reflects the temperature gradient between two dissimilar metal junctions and a reference point. The voltage generated is interpreted to identify the corresponding temperature.

Key Features of Thermocouples:

- Versatility: Available in various types (e.g., Type J, K, T, E) to suit specific applications.

- Temperature Range: Capable of measuring temperatures from -200°C to over 2000°C, depending on the type.

- Durability: Resistant to mechanical stress and high temperatures.

Advantages:

- Wide temperature range.

- Cost-effective, especially for high-temperature applications.

- Their rapid response is attributed to a low thermal mass, enabling quick detection of temperature changes.

Limitations:

- Less accurate than RTDs, with typical errors of ±2°C to ±5°C.

- Requires regular calibration for precise measurements.

- Voltage signals are small and can be affected by electrical noise.

- Thermistors

Thermistors are temperature-sensitive resistors made from ceramic or polymer materials. Their resistance decreases (Negative Temperature Coefficient, NTC) or increases (Positive Temperature Coefficient, PTC) significantly with temperature changes.

Key Features of Thermistors:

- Sensitivity: Extremely sensitive to small temperature changes.

- Temperature Range: Typically operate within -50°C to 150°C.

- Size: Compact and easy to integrate into electronic systems.

Advantages:

- High sensitivity enables precise detection of small temperature changes.

- Low cost and compact design.

- Quick response time.

Limitations:

- Limited temperature range.

- Non-linear response, requiring complex calibration.

- Thermistors tend to have lower durability in extreme or harsh environments when compared to RTDs and thermocouples.

Comparison Table

| Feature | RTD | Thermistor | Thermocouple |

| Accuracy | High (±0.1°C) | High in a limited range | Moderate (±2°C to ±5°C) |

| Temperature Range | -200°C to 600°C | -50°C to 150°C | -200°C to 2000°C |

| Durability | Fragile | Moderate | Highly durable |

| Cost | Expensive | Economical | Affordable to mid-range |

| Response Time | Intermediate | Quick | Rapid |

| Linearity | Near-linear | Non-linear | Non-linear |

Choosing the Right Sensor

Selecting a temperature sensor hinges on its intended use:

- RTDs: Preferred for applications needing high precision and consistent performance, such as in labs, industrial setups, and HVAC systems.

- Thermocouples: Well-suited for high-temperature or challenging environments, including metal forging, kilns, and aviation.

- Thermistors: Ideal for compact, cost-sensitive applications like household devices, medical instruments, and consumer gadgets.

Conclusion

RTDs, thermocouples, and thermistors are essential tools for temperature measurement, each with distinct strengths and weaknesses. Understanding their characteristics and applications ensures optimal performance and cost-efficiency in your projects. Whether you prioritize precision, range, or durability, selecting the appropriate sensor will significantly impact the success of your temperature-sensitive processes.