As industries evolve for increased resilience, their network infrastructures also grow more complex. Configuration, maintenance, and troubleshooting of such networks can be daunting. For low-hassle connectivity, industrial unmanaged switches offer a convenient, cost-effective way to expand growing networks.

In this article, we explore three applications of unmanaged switches for expanding industrial edge networks. Additionally, we’ll outline criteria to consider for optimal switch choice.

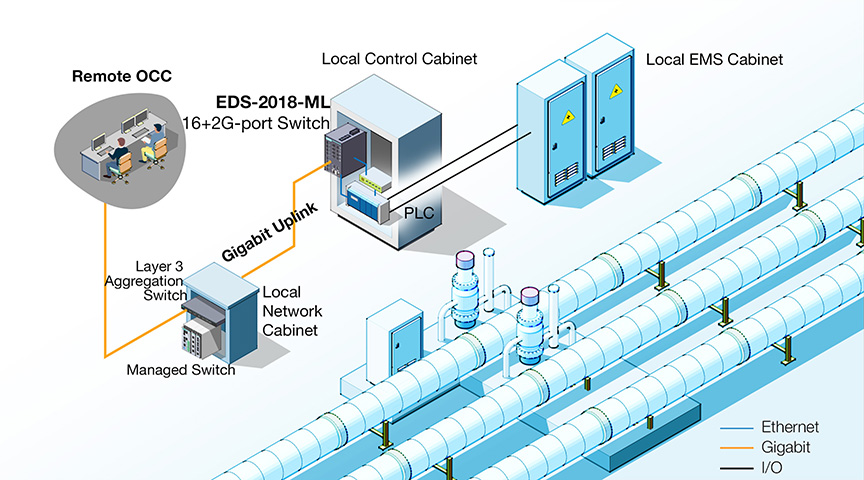

Application 1: Boosting Availability and Reducing Maintenance Costs for Field Instrumentation Data

An oil and gas company needed to expand its networks to keep pace with oil well exploration. Their field network was built to monitor and control field instruments dispersed among oil wells. Control cabinets needed simple, high-reliability connections to network cabinets to ensure alert notifications reach the remote OCC control centre for on-site monitoring.

The expanded network had the following requirements:

- Application and Environment: Rugged devices for operation in hazardous locations

- Reliability: Prioritize instant warnings for on-site monitoring

- Network Requirements: Enhanced electromagnetic noise resistance for EMS and I/O data transfer to a local network console

Application 2: Deploying Automated Guided Vehicles to Optimize Logistics

A logistics company has chosen to deploy AGV systems (Automated Guided Vehicles) in their warehouses, improving warehouse logistics to facilitate faster deliveries for customers. The deployment needed to integrate numerous devices into a space-constrained AGV, such as:

- PLC

- Motors

- RFID readers

- Wireless clients

- Network switch

Network reliability is crucial for the control center to continuously monitor and control AGV systems and optimize delivery operations.

System requirements include:

- Installation: Compact devices that can be easily installed in a space-constrained AGV

- Application and Environment: Durable, industrial-grade devices that can withstand harsh environments

- Reliability: Plug-and-forget durability to ensure continuous uptime

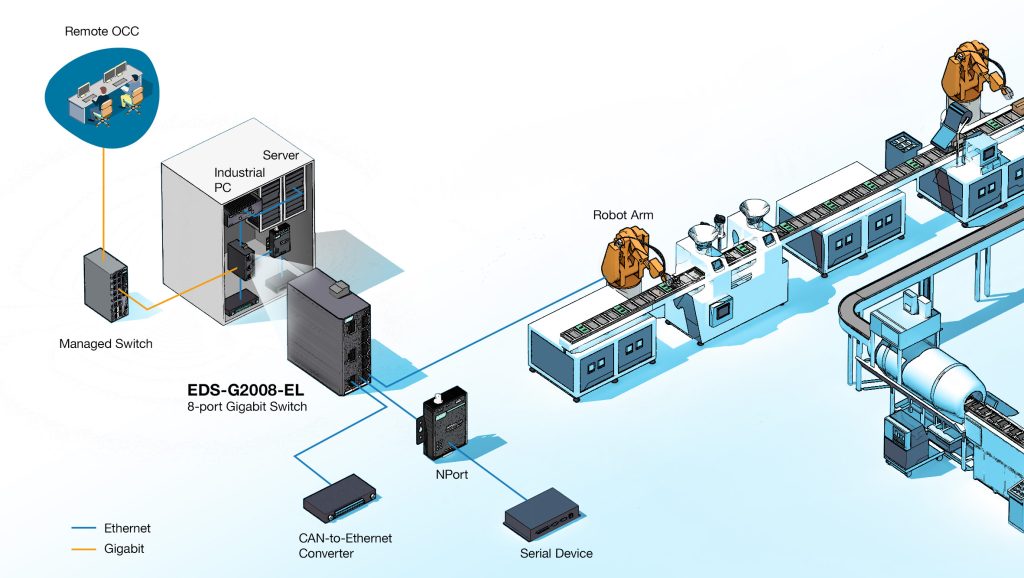

Application 3: Predictive Maintenance to Boost Operational Efficiency

A machine builder sought to offer predicative maintenance and enhanced efficiency to clients. To support these new services, the builder needed enhanced connectivity and monitoring in their machine cabinets to gather machine data to support these services. The high number of devices made reliable transmission paramount.

The expanded network had the following requirements:

- Network requirements: Upgrade to Gigabit Ethernet, as Fast Ethernet was no longer sufficient to facilitate a growing number of device connections

- Installation: Ensure quick deployment without the need for specialized IT skills, guaranteeing smooth operation and easy maintenance

- Reliability: Prioritize the transmission of crucial data for real-time applications

From these cases, we see that when networks expand at the edge, it’s vital that they retain simplicity and flexibility. Unmanaged Ethernet switches offer an easy-to-deploy, adaptable, and highly dependable solution, allowing control engineers to focus on their roles without worrying about connectivity.

Find the Best Fit for Your Application

Industrial unmanaged switches are simple to set up, but these handy devices come in many forms. Here are some factors to consider when choosing switches to find the best fit for your application and needs.

Reliability

- Dual Power: If uptime is crucial in your network, selecting switches with redundant power inputs prevents interruption from power outages.

- Software Features: Capabilities such as QoS (Quality of Service) and BSP (Broadcast Storm Protection) can help ensure data gets where it needs to go.

- Mean Time Between Failures (MTBF): The cost of downtime in an industrial environment can be high. Invest in switches from reputable brands with a higher MTBF.

Installation

- Ease of Configuration: Unmanaged switches are plug-and-play, making them popular among OT engineers.

- Device Size: Small switches enable flexible installation and can make room for future network expansion in space-constrained control cabinets.

Application and Environment

- Industrial Grade Housing: Selecting a switch with rugged housing, capable of withstanding harsh environmental conditions, is crucial for industrial networks.

- Operating temperature: Switch operating temperature range should be wide enough to cover potential extreme conditions.

- Certifications: For certain industries, such as transportation, maritime, railway, etc., additional certification may be required.

Network Requirements

- Bandwidth: Choosing a switch with adequate bandwidth for your applications. For applications where Fast Ethernet doesn’t offer enough capacity, Gigabit Ethernet may be preferable.

- Media Type: Fiber-optic media resists electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring data integrity even in harsh environments.

Ideal for Edge Network Expansion

Moxa offers a range of industrial unmanaged switches characterized by a compact design and exceptional durability. Ideal for facilitating network expansion at the edge, the EDS-2000 Series offers proven reliability, easy deployment, ample bandwidth, and adaptability across numerous industrial applications.