ROHM introduces new automotive LDO regulator ICs with stable operation at nanoscale output capacitance. The BD9xxN1 series BD950N1G-C, BD933N1G-C, BD900N1G-C, BD950N1WG-C, BD933N1WG-C, BD900N1WG-C) are optimized for primary (direct connection to 12V) power supplies in a wide range of applications, including powertrain, body, ADAS, and car infotainment.

In recent years, the continuing digitization of all types of equipment has been increasing the number of electronic components, which in turn has been driving the demand to reduce the number of capacitors used for circuit stabilization to shrink both the size and the bill of material (BOM). This requires power supply ICs in power supply circuits that can achieve stable operation with small-sized capacitors, but until now it had been difficult to achieve stable operation in applications with output capacitances of 1μF or less.

To meet these needs, ROHM developed the Nano Cap ultra-stable control technology for power supply ICs in 2020. Leveraging this technology enables ROHM designers to develop LDO regulators that ensure stable operation even at ultra-small nanoscale output capacitances.

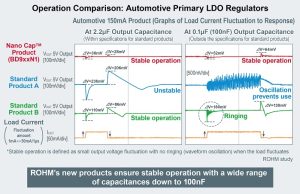

This enables the support of output capacitance of 100nF – less than 1/10 of the value of standard products – ensuring stable operation required by applications (output voltage variation within 100mV: condition is 1mA ⇔ 50mA/1μs load current variation), even when the input voltage and load current fluctuate.

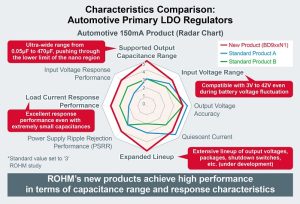

Furthermore, in addition to common μF-order MLCCs (Multi-Layer Ceramic Capacitors) and large capacitance electrolytic capacitors, ROHM’s new regulators can handle an ultra-wide range of output capacitances down to 1μF or less in the ultra-compact 0603/0402 size (which in the past had not been stable enough to be used), contributing not only to the miniaturization of components and boards but also to a reduction of design resources needed by supporting a wider range of capacitor conditions.

Going forward, ROHM is expanding the LDO regulator series with built-in Nano Cap technology to 22 models in different output voltages and packages by the end of FY2022. In 2023, another 24 models will be added to support 500mA output current, for a total of 46 products by the end of FY2023, covering an even broader range of applications.

What is Nano Cap Technology?

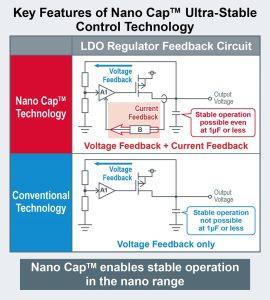

Nano Cap refers to ultra-stable control technology achieved by combining advanced analog expertise covering circuit design, processes, and layout utilizing ROHM’s vertically integrated production system. Stable control eliminates the problem of unstable operation related to capacitors in analog circuits, contributing to a reduction in design resources for a wide range of applications in automotive, industrial equipment, consumer, and other fields.

New Product Details

The new BD9xxN1 series of automotive primary LDOs meets the basic requirements of automotive products, such as operation above 125°C, qualification under the AEC-Q100 automotive reliability standard, and input voltages greater than 40V for the primary power supply. Incorporating ROHM’s Nano CapTM ultra-stable control technology supports an output capacitance of 100nF, which is less than 1/10 of the value of standard products, to ensure stable operation required by applications (output voltage variation within 100mV: condition is 1mA ⇔ 50mA/1μs load current variation) even when the input voltage and load current fluctuate. This makes it possible to provide high performance with a good balance in terms of output capacitance range and response characteristics.

Application Examples

◇ Powertrain (i.e. fuel injection) and tire pressure monitoring systems (TPMS)

◇ Body systems (e.g. body control modules)

◇ ADAS (e.g. Domain Controllers, ECUs, Zonal processing)

◇ Infotainment including instrument clusters and head-up displays (HUD)

Suitable for a wide range of applications in addition to automotive primary power supply systems.

Support Tools

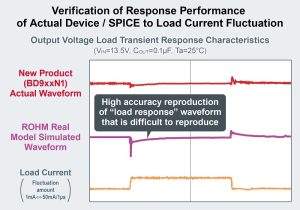

As a simulation model for verifying these new products, ROHM Real Model is a high-accuracy SPICE model that utilizes original model-based technology to faithfully reproduce the electrical and temperature characteristics of the actual IC, resulting in an outstanding match between the IC and simulation values such as “load response” waveform which is difficult to reproduce. This ensures reliable verification, contributing to more efficient application development – for example by preventing rework after prototyping.

For more information, visit www.rohm.com/products