BigRep, a prominent player in the field of additive manufacturing, has developed two cutting-edge 3D printers designed specifically for industrial applications. The ALTRA 280 and IPSO 105, engineered to deliver speed, reliability, precision, and automation, mark a significant advancement in the realm of high-temperature 3D printing.

The ALTRA 280 and IPSO 105 represent BigRep’s commitment to meeting the evolving needs of industries such as aerospace, defence, and automotive. These printers are equipped to handle a wide range of materials, from standard polymers to high-performance ones, making them versatile solutions for various manufacturing requirements.

Key Features of ALTRA 280

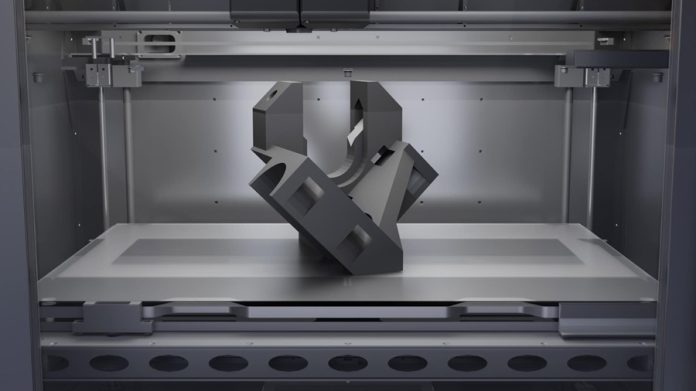

The ALTRA 280 boasts a large-scale printing capability, with dimensions of 500mm x 700mm x 800mm, allowing for the production of intricate and sizable components. Its high-temperature capabilities, reaching up to 450°C, enable the printing of robust parts suitable for challenging industrial applications. The machine is designed for uninterrupted productivity, thanks to its dual extrusion system and backup systems, ensuring reliable performance around the clock.

Key Features of IPSO 105

On the other hand, the IPSO 105 offers a generous toolmaker’s build volume of 400mm x 600mm x 440mm, catering to a wide range of applications from tooling to end-use parts. With high-temperature capabilities of up to 180°C, the IPSO 105 can handle a variety of engineering-grade and high-performance materials, including multi-material parts facilitated by its dual extrusion system. The automated start and production processes enhance reliability and streamline operations.

Industry Impact and Significance

Both the ALTRA 280 and IPSO 105 are seen as game-changers in the field of industrial additive manufacturing. Their ability to accommodate diverse polymers, coupled with all-temperature capabilities, positions them as pivotal solutions for industries requiring high-performance parts. Thomas Janics, from HAGE3D, anticipates a transformative impact on additive manufacturing, particularly in sectors with demanding specifications.

Conclusion

BigRep’s introduction of the ALTRA 280 and IPSO 105 represents a significant leap forward in the realm of high-temperature 3D printing. These printers, engineered with a focus on speed, reliability, precision, and automation, are poised to revolutionize industrial additive manufacturing across sectors such as aerospace, defense, and automotive. With their advanced features and capabilities, they offer manufacturers the tools they need to stay competitive and innovative in today’s rapidly evolving manufacturing landscape.