Researchers have toiled for years, unsuccessfully, in pursuit of a silica optical fibre that would cool itself when excited with infrared laser light.

Such a fibre would make it possible to use the most ubiquitous type of laser fibre—silica—without having to cool it externally and, theoretically, produce laser-based devices with exceptionally pure and stable frequencies.

“Instead of removing the heat from the laser, which takes some doing, you just don’t generate the heat in the first place,” said Michel Digonnet, who is a research professor of applied physics at the School of Humanities and Sciences at Stanford University.

A self-cooling laser could be used, for example, to create advanced fibre amplifiers—devices that amplify light signals that travel through them and are instrumental in transporting information encoded on optical signals over very long distances. Currently, this process generates heat that degrades the quality of the light signal; using a self-cooled fibre would eliminate this problem.

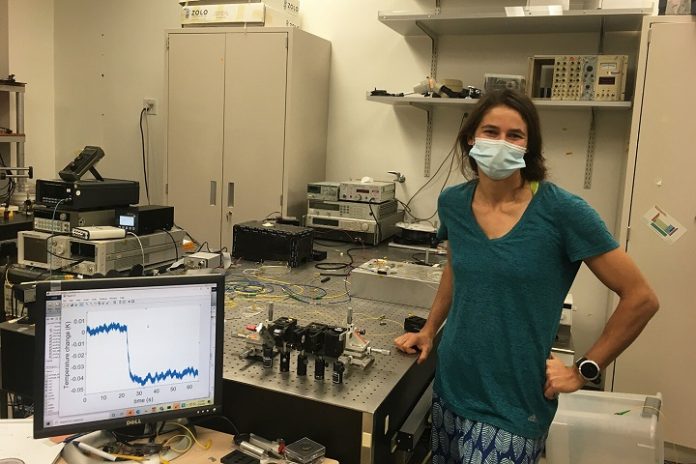

But finding the right silica composition has proven elusive to the point where some experts thought achieving this goal was highly unlikely, if not impossible. The generally low expectations forever finding this fibre had given Stanford graduate student Jennifer Knall enough doubt, that when she finally witnessed the first signs of self-cooling in her silica fibre experiments, she ran the tests again. And again. And again.

“Secretly, I had almost given up hope,” said Knall, who is a graduate student in electrical engineering. “But the theory was solid, and we had really amazing collaborators who were willing to listen to us and keep making optical fibres. So I kept testing.”

The first fibre

The confirmation came late at night. After a few tests using silica fibre that failed to demonstrate any cooling when pumped with laser light, Knall decided to repeat the experiment using light with lower energy. The difference in energy was very small, but it changed everything. When the temperature measurement graph loaded on her screen, there was a dip.

“I thought, “There’s no way.” I didn’t want to get my hopes up because it could have been misleading fluctuations in the measurements from the temperature sensor,” said Knall.

So, she redid the measurement. Six more times. The dip was consistent, and Knall became the first person to witness a silica optical fibre that got colder, not hotter when excited by light. “I sent out an email to everyone in all caps: WE DID IT.”

The temperature of a self-cooling silica fibre laser doesn’t fluctuate, so the frequency and power of the light that they emit are more stable over time than lasers with external cooling. This results in an emission that is more consistent colour, or wavelength, of light.

“All of a sudden this wonderful idea is applicable to the most common laser material in a fibre form, which we didn’t think was possible six months ago,” Digonnet said.

They have also recently integrated the silica fibre into a laser amplifier. In the long run, Digonnet and Knall also need to figure out how the laser amplifier can run more efficiently so that it can be used for large-scale high-power laser applications.

In the near term, this fibre could prove extremely valuable for low-power science applications aimed at gathering high-precision measurements of physical parameters such as acceleration, acoustic waves or strain.

Keeping it cool

To appreciate the significance of this breakthrough, one must understand some simple facts about lasers. Lasers are special for the intensity and monochromaticity of the light they produce. Fibre-based lasers are fibres that convert chaotic, spectrally broad “pump” light into high-purity monochromatic light.

But in the process of producing laser light, fibre-based lasers, like all lasers, heat up in undesirable ways. This problem is currently solved by adding bulky, water-based cooling systems, which produce other detrimental effects. A silica fibre that can self-cool results in cleaner laser light.

This form of cooling occurs when a rare-earth ion added to the fibre (such as ytterbium) absorbs low-energy light and then emits light at a slightly higher energy level. This process, known as anti-Stokes fluorescence, leads to a reduction in fibre temperature.

This is challenging in silica, however, because the energy from an excited ytterbium ion can jump to an impurity in the fibre and release energy as heat through a process known as “concentration quenching.” Still, Knall and Digonnet knew that theoretically at least, there should be a suitable fibre composition for laser cooling in silica.

“The challenge was to find the material that would host as much ytterbium as possible without having the quenching effect,” said Digonnet. “When the concentration of ytterbium is too low, the cooling is too small. When it is too high, the ions lose their cooling efficiency. We needed to find a glass composition that pushed the balance between these two opposing effects toward a higher concentration.”

Undeniably useful

Since their first breakthrough, the researchers have found two more silica fibre compositions that self-cool, and Knall has used the best performing candidate to create a cooled fibre amplifier. She has been able to amplify laser light more than 40-fold while maintaining a negative average temperature change along the length of the fibre. Whereas the cooling tests proved that laser cooling in silica is possible, this fibre amplifier shows that it is also undeniably useful in practice.

Right now, the researchers extract around 4 per cent of the energy they inject into the fibres. This makes it unlikely that the fibres would be adopted for high-power applications without first increasing this low efficiency, but the researchers see many opportunities for extremely stable lasers in lower-power applications, such as extremely precise metrology, or the science of measurements.

“How far we can take this technology will depend on how much researchers can push the materials science,” said Digonnet. “This is just the tip of the iceberg.”