The last 15 years in the electricity metering industry have witnessed multiple waves of change with a scope and size not seen since the days of Edison and Tesla. The transition from electromechanical to electronic meters was followed by automatic meter reading (AMR) systems, which in turn evolved into advanced metering infrastructure (AMI) systems with higher speed, two-way communication, and the ability to deliver large amounts of data to central databases for billing, troubleshooting, and analysis.

Undeniably, those changes brought in business efficiencies ranging from drastically reduced labor hours for reading millions of meters, to improved access (as anyone who has seen a utility key room appreciates), to worker safety (such as a reduction of meter reader dog bites), to lower environmental impact from fewer truck rolls.

Despite these advancements, the primary function of the AMI network is still making sure all electricity consumption is measured and accounted for.

Beyond Meter-to-Cash

The rising competitiveness in the industry, increased regulations, and demand for customized services are putting greater pressure on utilities to manage assets cost-effectively, provide exceptional customer service, and modernize processes. The promise of IoT includes translating various sensor-based information into action—new services, crew localization, part inventories, and the control and maintenance of assets.

An electrical utility commercial director or a head of metering are still left with unresolved inefficiencies around maintaining the health of millions of meters on a case-by-case basis, verifying accuracy using imperfect statistical methods, disrupting service for testing, replacing meters prematurely, or using age-based decision making.

Meter Health at Your Fingertips

For years, we have been told that the measurement technology in electricity meters is commoditized, therefore we put all our efforts into delivering value from analyzing the available electricity data. What if the tables have flipped and the way to extract more value out of AMI systems is to upgrade the measurement with new diagnostics making the already smart meters even smarter.

A technology that can nonintrusively monitor the health of deployed meters, including the accuracy of the current and voltage sensors, and better detect meter tampering can save significant cost for electrical utilities.

Intelligence based on direct measurement of meter health will help make decisions quickly and with confidence by identifying out-of-specification meters, detecting meter malfunction, and confirming and quantifying more tamper events. Utility companies will then be able to more effectively dispatch field crews, optimize meter replacement, and reduce tamper investigation time.

An Edge-to-Cloud Utility Meter Analytics Solution

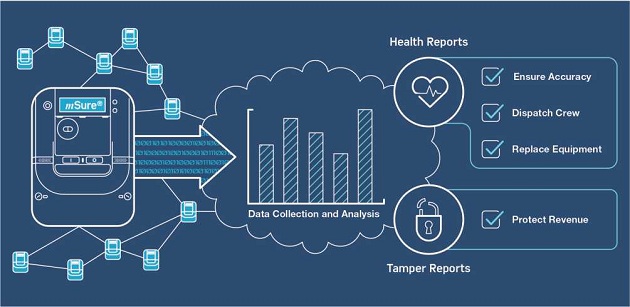

Analog Devices, a veteran in the electricity industry, has created an analytics solution featuring a real-time diagnostic technology—mSure—residing in the individual utility meter that reports meter health data to an analytics service. The resulting actionable insights provide utilities with a direct ability to protect revenue better, manage field resources more effectively, reduce equipment costs, and improve customer service.

mSure Diagnostics

mSure is a noninvasive diagnostics technology that monitors sensors for accuracy and faults. In utility meters, it is built into the new Analog Devices’ energy measurement IC and it delivers meter health data.

mSure-Enabled Meters

An mSure-enabled meter has the ability to check the accuracy of the metrology function directly and in real-time.

Cloud-Based Analytics

The analytics service combines various data sources and data history to provide actionable insights via advanced meter health and revenue protection modules.

Closer Look at ROI:

Eliminating Meter Accuracy Verification

Regulatory compliance sometimes requires checking the accuracy of up to 0.5% of all installed meters twice during a meter’s lifetime. A utility with 10M meters installed could easily incur a cost of $7.5M over the lifetime of the population. $75 cost per customer assumes removing the meter under test, installing a new one, performing the test in a lab, and then installing the original meter for another customer. In-field accuracy verification can prove even costlier and inconvenience customers. An mSure-enabled meter checks the accuracy of the entire metrology function, while in the field and in full operation, leading to direct cost savings and customer service improvements.

Extended Meter Lifetime

The most common method for determining when to replace meters is based primarily on length of service. For this method to be effective, the meter must be replaced before the first meter is expected to fail.

Therefore, almost every meter that is thrown into the trash still functions. Being able to precisely and cost effectively check meter accuracy helps enable utility companies to make better replacement decisions. If we assume a $100 cost for the new meter and its installation, and by achieving a 2-year extension to a 15-year meter lifetime, over $10 can be saved per meter over its lifetime.

Reduced Risk

Today’s electricity meter manufacturers provide an amazing level of quality, but due to a variety of factors, there is always a chance that a meter will fail in the field and overbill a customer. Many PR departments and meter managers have a horror story about overbilled customers who have turned to social media to express their dissatisfaction. An mSure- enabled meter can perform a background accuracy check multiple times a day, and send an alert if it detects a change in meter accuracy so that an overbill situation can be detected quickly and remedied before it becomes a larger problem.

Advanced Revenue Protection

Meter tampering is a significant problem in some parts of the world, with an estimated $96B per year of electricity stolen worldwide according to the Northeast Group. Unlike other methods for tamper detection, Analog Devices mSure technology is based on an always-on direct measurement of meter sensor functionality and not statistical or subjective factors, which enables it to:

- Deliver high confidence results with fewer false positives

- Detect new types of tampering never detected before

- Specify tampering to an individual meter

- Detect intermittent tampering (for example, during times when meter crews are off duty)

- Estimate the amount of tampering, which helps prioritize tampering investigations

The financial benefits of mSure-enabled revenue protection will vary by utility, depending on the amount of tamper, the types of tamper, and the ability to pursue enforcement. For a 10M meter utility with a 1.5% nontechnical revenue loss rate, tamper is a $60M issue. Assuming a 15% improvement in recovery, an mSure-enabled meter can save a utility over $10 per meter over the meter’s 15-year lifetime.

Conclusion

Each wave of change to hit the electricity metering industry has caused significant improvements in operational efficiency and provided good return on investment. Leading utility companies considering new meter deployments need to consider if adding in-meter diagnostics can boost their return on investment in next-generation meters. mSure-enabled meters and Analog Devices’ analytics services enable multiple improvements, including eliminating meter accuracy verification, extending meter lifetime, reducing risk, or adding advanced revenue protection.

Source: Analog Devices