As electronic components are becoming smaller and smaller, the demands for heat withdrawal are increasing. For optimization purposes, an examination of temperature conditions using a thermal imager is expedient, and the analysis of warming and cooling behaviour over defined time intervals is often required. Only high-quality thermal imagers with the highest geometric resolution and the possibility of recording fully radiometric video sequences are up to this job.

The challenge:

The miniaturization trend in electronic components continues – and with it, the requirements regarding heat transfer: even the smallest components in the narrowest spaces create heat which can affect the component itself or adjacent assemblies. Especially the development of heat over time can negatively influence the functionality and life expectancy of an instrument. Thermography is an effective tool for the optimum dimensioning and positioning of electronic components for an ideal circuit board layout: It allows temperature distribution and development to be identified without contact even in the smallest scales. Since thermal curves frequently also need to be taken into consideration, individual thermal images are often not sufficient.

The solution:

Identify even the smallest faults

Thermography of microelectronics and other measurement objects with very fine structures requires a high geometric resolution. This is the only way the smallest structures can be measured reliably. A detector size of 640 x 480 pixels is indispensable for this purpose. The Testo 890 provides this – and with it, 307200 individual measurement values. In combination with a 42° lens, the thermal imager thus allows a focus distance of only 10 cm. This makes the resolution of tiny structures of only 113 μm possible. If the camera is being used in a hand-held operation, the SuperResolution technology can additionally be applied. This patent-pending innovation from Testo records several images one after the other in the shortest possible time and slightly offset to each other. Using an algorithm, these are then calculated into a single thermal image with four times the number of measurement values. Even higher-resolution images than usual – up to 70 µm – are then available when subsequently viewing the data in the professional analysis software IRSoft.

Analyze heat development as a time progression

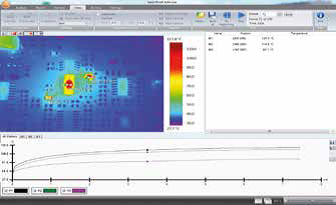

If the development of temperatures needs to be observed over time, the Testo 890 is able to record a sequence from a series of images. You obtain radiometric image sequences which allow you to evaluate the temperature in the thermal image for every point in the time progression and at every position of the measurement object. This avoids time-consuming searches. The recording is made at individually configurable intervals, and can be started manually or after a timer countdown. After finishing the measurement, you can examine the recorded sequences conveniently at a PC in the professional analysis software IRSoft. If your workplace provides space for a more extensive experimental set-up with your thermal imager, you can connect the Testo 890 to a PC via USB interface, and use the fully radiometric video streaming in the IRSoft function “fully radiometric video measurement”. Here you benefit from a higher recording speed of up to 25 Hz. In order to evaluate temperature developments as a time progression, you can present measurement points and profile lines as a temperature-time diagram, which you can then export as a graph or Excel file.

Image 1: Presentation of the heating process of several processors on a circuit board in a temperature-time diagram in the IRSoft.

Work only with relevant data

If you need to be able to record thermal images only above a certain thermal limit value, you can benefit from Testo 890’s automatic, limit value-based trigger. This triggers the thermal imager only when a limit value defined by you has been reached. This function has the further advantage that you only record data which are really relevant to the development of your product. The viewing of unnecessary measurement data can be dispensed with, resulting in further time savings.

In a nutshell:

With the thermal imager Testo 890, you can:

• Record image sequences directly in the imager, thus visualizing thermal processes in high resolution

• Work more efficiently with an automatic, limit value-based trigger

• Transfer the measured data to temperature-time diagrams and Excel

Image 2: Testo 890 Thermal Imager