Over the years 3D printing has become increasingly popular throughout the research and design world. 3D printing is the process of laying down successive layers of material until a three-dimensional object forms. The demand for this technology has grown because of its proven time and cost savings. Unlike machining, when 3D printing a part, there is little to no waste involved because you add material as needed, instead of cutting away.

This technology was first created to print small prototypes to evaluate new designs in manufacturing processes. Today, 3D printing is used in just about every industry, and not just for prototyping. 3D printing is also being used in the art industry. With the help of fluid dispensing technology such as Nordson EFD’s PICO Pµlse jet valve, students at MIT were able to reproduce near-flawless replicas of fine art pieces. These replicas are often distributed to museums that cannot gain access to originals, hence the need for flawless execution.

An Arrangement in Color and Gloss

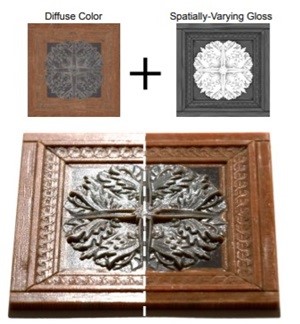

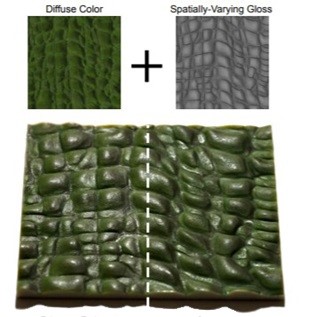

To replicate fine art, the students were tasked with fabricating a technology that could deposit colored materials with high spatial resolution, while also applying a glossy material known as varnish over the printed art piece. Adding the gloss was a crucial component for their success because the varnish improves the surface quality once the paint dries. Without adding a varnish, you can often be left with an uneven surface and the product can look unfinished.

One of the main challenges in fabricating spatially varying gloss properties lies in the printing process itself. 3D printers cannot print glossy materials because the printing nozzles cannot print highly viscous materials with large particle sizes. As a result, the same nozzles that are required for achieving high-resolution prints like the ones used in 3D printers, are not suitable for printing a wide range of glosses.

Dispensing High-Viscosity, Particle-Filled Materials

To overcome the limitation of printing the gloss, the students proposed a printing system based on Nordson EFD’s PICO Pµlse jetting technology and another supplier’s ink-jet 3D printing solution.

Combined, the two technologies were capable of dispensing materials with very high viscosity and relatively large particle sizes, as well as print in the color and shape needed to replicate the fine art piece. Jet dispensing the high-viscosity material allowed the students to control the glossiness of a surface to ensure an even layer throughout, while also using off-the-shelf varnishes.

The PICO Pµlse delivers faster, more precise jetting over any surface, including uneven and hard-to-reach surfaces, which made this valve a great fit for dispensing varnish onto intricate art pieces. It dispensed the varnish with less turbulence for greater fluid deposit consistency and placement. This helped create the near flawless fine art replicas required.

The complete system that the students were able to fabricate included three PICO Pµlse jet valve systems, a robot, a gantry, and a controller. The robot was used to move and locate the dispensers along the Z-axis and the art piece along X and Y-axis. The PICO Pµlse was used to deposit different varnishes with different viscosities. The movement of the robot and the pulse time of the valves were coordinated by the controller.

From Unfinished to Flawless

Using the new modified 3D printing system, the students were able to optimize a set of printable varnishes capable of being consistently dispensed at a 450 μm resolution. With this system, they can successfully jet varnishes with a wide range of viscosities and handle matte varnishes with particles. This capability allows the students to achieve broad coverage of reflectance from very glossy to matte depending on the finished outcome they are looking to achieve.