Author: Pankaj Raut, CEO and Co-founder at Ajna Lens

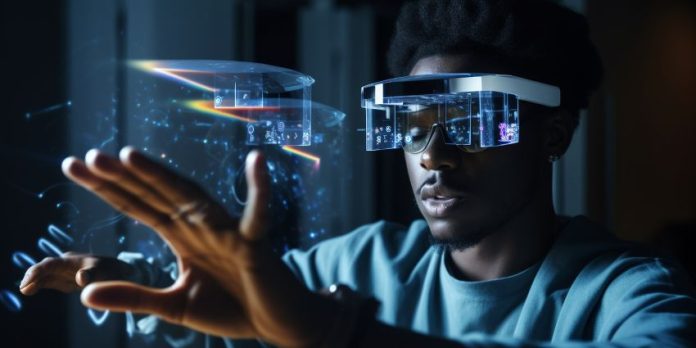

As we soar into a new era of technological advancement, the world finds itself on the cusp of a transformation with Extended Reality (XR).

Statistics paints a compelling picture: The global XR market is expected to reach a staggering $1,134.79 billion by 2030, with a phenomenal growth rate. While still nascent, XR holds the potential to reshape every aspect of Aerospace & Defence (A&D) from design and training to maintenance and operations.

For instance, try to imagine pilots undergoing hyper-realistic, multi-sensory flight simulations in virtual battlefields, honing their skills in controlled environments that replicate G-forces, turbulence and even enemy encounters. Ground crew wearing AR glasses remotely collaborating with specialists across continents, troubleshooting glitches in real-time with the aid of shared, interactive XR experiences.

Imagine dissecting a complex rocket engine, guided by interactive overlays highlighting potential issues before launch. Or picture yourself collaborating with colleagues across continents in a holographic workspace, designing the next-generation aircraft. Extended Reality (XR) is poised to revolutionise not just science fiction, but the very core of A&D.

From Blueprints to Holographic Workspaces

Gone are the days of clunky headsets and pixelated screens. Think of all the innovation waiting in the wings to completely enhance the design and prototyping. The aerospace industry thrives on innovation, but traditional physical prototyping can be expensive and time-consuming. XR offers a game-changer. Imagine engineers interacting with 3D models in real-time, manipulating them in virtual space, and identifying design flaws or optimising performance virtually before expensive physical prototypes are built. Studies by Deloitte show that XR design tools can reduce prototyping costs by up to 70%, leading to faster innovation cycles and a competitive edge.

Revolutionising Training with Immersive Simulations

Piloting a multi-million dollar aircraft or performing intricate maintenance tasks require meticulous training. Traditional methods often lack the nuance and realism needed to fully prepare personnel for real-world scenarios. XR creates immersive simulations that replicate real-world scenarios with unparalleled fidelity, incorporating factors like G-force, turbulence and even simulated enemy encounters.

A study by the Air Force Research Lab found that pilots trained with VR flight simulators showed a 40% reduction in training time and a 30% improvement in mission performance compared to traditional methods. This translates to safer missions, reduced costs and improved operational readiness.

Streamlining Maintenance with Augmented Guidance

Downtime due to equipment failure is costly and can compromise mission success. With XR, technicians can wear AR glasses, receive real-time instructions and overlay critical information onto physical equipment. This remote collaboration and augmented guidance enables faster, more accurate repairs. A study by Boeing found that using AR for maintenance tasks reduced overall repair time by 30% and improved first-time fix rates by 20%. This translates to minimising downtime, optimising resource allocation and improving operational efficiency.

Logistics Transformed with Enhanced Precision

On top of all this, the A&D industry’s complex supply chains demand precision and efficiency, where AR can transform logistics and operations, through real-time inventory tracking, visualised warehouse layouts, and efficient picking and packing processes. Imagine technicians wearing AR glasses, guided through warehouses with inventory locations highlighted and picking routes optimised. This translates to faster deliveries, reduced errors and optimised resource allocation.

Challenges on the Horizon

Despite the potential, challenges linger. Cost and accessibility of technology, privacy concerns and the need for robust cybersecurity measures are valid hurdles. Additionally, integrating XR seamlessly into existing workflows and infrastructure requires careful planning and collaboration. Addressing these challenges requires a collaborative effort from industry leaders, policymakers and technology developers.

Partnerships Fueling Innovation

The Indian government recognizes the transformative potential of XR and is actively fostering its adoption in A&D. Ergo, the government allocated ₹475 crore (US$64 million) for the iDEX program in the 2023-24 budget, highlighting its commitment to fostering innovation in defence. Initiatives like Innovations for Defence Excellence (iDEX) serve as collaborative platforms, bridging the gap between startups and defence forces.

This not only fast-tracks the infusion of innovative technologies into our nation’s defence capabilities but also empowers startups by offering financial backing, mentorship and resources. Additionally, the Make in India initiative promotes indigenous manufacturing, reducing external dependency and encouraging self-reliance. As of March 2023, the “Make in India” initiative has attracted foreign direct investment (FDI) worth ₹83,572 crore (US$111.9 billion) in the defence sector. Agile and innovative startups play a pivotal role in this journey, contributing to the development of cutting-edge defence technologies and products tailored to specific needs.

The Future is Immersive

The mass adoption of XR in A&D is not a question of “if,” but “when.” By embracing this transformative technology, we can ensure safer operations, more efficient training and accelerated innovation. The multiple collaborating initiatives with A&D professionals in the Indian government and the XR startups around the country hints towards the skies of the future – a future painted in the vivid colours of Extended Reality.