Nuvoton Technology Corporation Japan (NTCJ) has developed new industrial 17-cell BM-ICs “KA49701A” and “KA49702A” for 48V batteries. Mass production starts from April 2025. These products enhance the safety of battery systems and simple safe system construction.

Achievements:

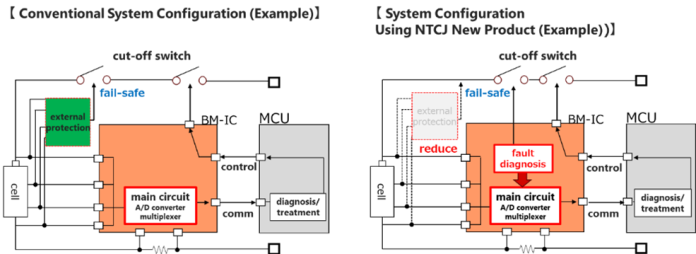

- By incorporating fault diagnosis and fail-safe functions within the battery monitoring IC(BM-IC), it is possible to build a safe system without external protection circuits. This contributes to improved safety of the Battery Management System (BMS) and reduced system costs.

- Achieves industry-leading voltage measurement accuracy of +/-2.9mV, allowing maximum utilization of battery capacity.

- Reduces current consumption during operation, enabling long battery drive times. Additionally, by reducing current consumption during shutdown, self-discharge is minimized, allowing for long-distance transportation and long-term storage of battery packs.

The expansion of renewable energy adoption and the development and expansion of data centers of generative AI are progressing. Energy storage systems responsible for stable power supply require larger capacity and higher output batteries. Consequently, the shift from traditional lead-acid batteries to smaller, lighter, and higher energy density lithium-ion batteries (LIB) is accelerating. However, LIBs are more expensive than lead-acid batteries and require systems to prevent fires, leading to increased manufacturing costs.

To address this challenge, we have developed a “48V BM-IC for Industrial Equipment ” equipped with fault diagnosis and fail-safe functions, leveraging our automotive battery control technology cultivated over many years. This product achieves both enhanced battery system safety and reduced system cost for LIB-equipped storage systems. Additionally, with an industry-leading voltage measurement accuracy of +/-2.9mV and low power consumption during both operation and shutdown (1/10 of our previous products), it maximizes battery capacity utilization.

Features:

- By integrating fault diagnosis functions and fail-safe functions within the BM-IC, it is possible to build a safe system without external protection circuits. This contributes to improved safety of the BMS and reduced system costs.

The battery monitoring IC plays a role in ensuring the system operates safely during anomalies such as overcharging or over-discharging of the battery. However, if the main circuits performing cell voltage measurements such as the AD converter or multiplexer of the BM-IC fail, it needs to ensure system safety with external protection circuits, but this increases board area and system cost. The major internal circuits of this product are equipped with diagnostic functions and fail-safe functions. This diagnostic function can detect main circuit failures and control·the cut-off switch, achieving both enhanced BMS safety and reduced system cost.

2. Achieving industry-leading voltage measurement accuracy of +/-2.9mV allows maximum utilization of battery capacity.

By reducing noise levels on the 16-bit AD converter and incorporating a digital filter, we have achieved industry-leading voltage measurement accuracy of +/-2.9mV. By improving voltage measurement accuracy, maximum Battery capacity can be used. Furthermore, precise voltage measurement has been achieved over a wide temperature range. It is also suitable for applications requiring high voltage measurement accuracy in cold and hot environments, such as stationary battery systems compliant with the Chinese national standard.

3. Reducing current consumption during operation realizes long-term Battery operation. Additionally, by reducing current consumption during shutdown, self-discharge can be minimized, enabling long-distance transportation and long-term storage of battery packs.

By shortening the cell voltage measurement time, which has high power consumption, operating current has been achieved at 260μA, less than 1/10th of our previous standards. This enables long battery drive times. Also, optimization of the circuit design has reduced shutdown current consumption to 0.1μA or less. Using our IC, self-discharge can be minimized, preventing deterioration due to over-discharge when LIBs are transported over long distances and stored long-term.

Applications:

Battery systems (Energy Storage System), backup unit for data centers,

Automated guided robots, electric bicycles, drones, etc.

Product name:

BM-IC for industrial equipment

KA49701A, KA49702A

| Model Number | KA49701A | KA49702A | ||

| Charge/discharge control method | Low-side switch | High-side switch | ||

| Maximum number of connected cells | 17 cells | |||

| Rated voltage | 85V | |||

| Voltage Measurement Accuracy | +/- 2.9mV | |||

| Current Measurement Accuracy | +/- 1.0% | |||

| Current Consumption

(Operating) |

260μA | |||

| Current Consumption

(Shutdown) |

0.1μA max | |||

Package |

QFP-48pin (7mm x 7mm) | |||