Researchers from North Carolina State University have developed a new process that makes use of existing industry-standard techniques for making III-nitride semiconductor materials, but results in layered materials that will make LEDs and lasers more efficient.

III-nitride semiconductor materials are wide-bandgap semiconductors that are of particular interest in optic and photonic applications because they can be used to create lasers and LEDs that produce light in the visible bandwidth range. And when it comes to large-scale manufacturing, III-nitride semiconductor materials produced using a technique called metal organic chemical vapor deposition (MOCVD).

Semiconductor devices require two materials, a “p-type” and an “n-type.” Electrons move from the n-type material to the p-type material. This is made possible by creating a p-type material that has “holes,” or spaces that electrons can move into.

A challenge for people who make LEDs and lasers has been that there was a limit on the number of holes that you can make in p-type III-nitride semiconductor materials that are created using MOCVD. But that limit just went up.

“We have developed a process that produces the highest concentration of holes in p-type material in any III-Nitride semiconductor made using MOCVD,” says Salah Bedair, co-author of a paper on the work and a distinguished professor of electrical and computer engineering at NC State. “And this is high quality material – very few defects – making it suitable for use in a variety of devices.”

In practical terms, this means more of the energy input in LEDs is converted into light. For lasers, it means that less of the energy input will be wasted as heat by reducing the metal contact resistance.

LEDs contain three main layers: an n-type layer where electrons originate; the so-called “active region,” which consists of multiple quantum wells of indium gallium nitride and gallium nitride; and a p-type layer, where the holes originate.

To produce semiconductor materials for use in LEDs or laser diodes, the researchers use a growth technique called “semibulk growth” to produce indium gallium nitride templates. The template is made of dozens of layers of indium gallium nitride and gallium nitride. The researchers use these templates for the n-type region to reduce complications that arise with the growth of the quantum wells. The insertion of the gallium nitride layer in between the indium gallium nitride layers in semibulk reduces defects due to the lattice mismatch between the semibulk template and the gallium nitride substrate, as well as filling the pits that form on the surface.

In their new work, the researchers demonstrated that the semibulk growth approach can be used for the p-type layer in LEDs to increase the number of holes. This new approach is cost effective from a manufacturing standpoint, since III-nitride based LED devices can be done in one growth via MOCVD, without a lengthy processing time in between.

Using this technique, the researchers were able to achieve a hole density of 5 × 1019 cm-3 in the p-type material. Previously, the highest hole concentration achieved in p-type III-nitride materials using MOCVD was about an order of magnitude lower.

The researchers also applied these indium gallium nitride templates as substrates for LED structures to address the long-lasting problem called the “green gap,” where the LED output deteriorates when emitting in the green and yellow part of the spectrum.

One of the main reasons for the green gap is the large lattice mismatch between the light emitting part of the material, the quantum well, when gallium nitride substrates are used. The researchers have demonstrated that replacing the gallium nitride substrates with indium gallium nitride templates results in improved LED performances.

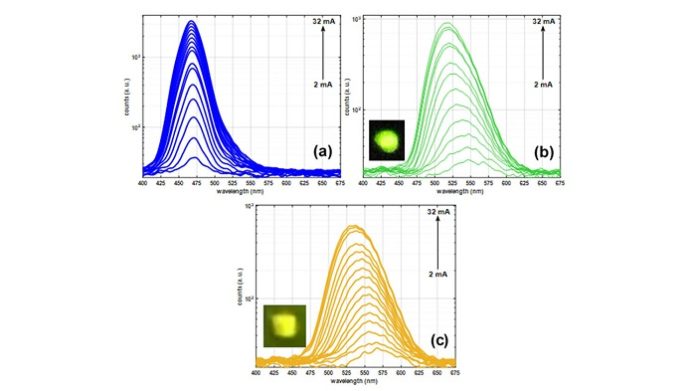

The researchers compared the LED emission spectrum for the same quantum well emitting in blue when grown on gallium nitride substrate and emitting either in green or yellow when grown on different indium gallium nitride templates. A 100 nm shift in the emission wavelength was achieved due to the application of the indium gallium nitride templates.

Improved efficiency, “P-type InxGa1-xN semibulk templates (0.02 < x < 0.16) with room temperature hole concentration of mid-1019 cm-3 and device quality surface morphology,” The Researchers are Evyn Routh and Mostafa Abdelhamid, who are both Ph.D. students at NC State. Peter Colter, a postdoctoral researcher at NC State; and by Nadia El-Masry of the National Science Foundation and NC State. Addressing the green gap in LEDs, “Shifting LED emission from blue to the green gap spectral range using In0.12Ga0.88N relaxed templates.”