Researchers at Politecnico di Torino, BRIN in Indonesia, the Italian Institute of Technology (IIT), and the University of Cagliari have recently introduced new composite hydrogel inks based on natural and environment-friendly materials, which could be used for 3D printing objects. These hydrogels are based on acrylated-carboxymethyl cellulose (mCMC).

“We have been working on the development of new printable materials and functional devices since 2015, so in these years different areas were explored, resulting in many publications in the field of 3D printing,” Ignazio Roppolo, one of the researchers who carried out the study.

The first objective of the work by Roppolo and his colleagues was to develop polymeric hydrogels for 3D printing that are based on natural resources, increase sustainability, and reduce the use of standard synthetic resins. In recent years, the team has been collaborating with Dr. Athanasia Amanda Septevani, a researcher at BRIN’s Research Center for Environment and Clean Technology in Indonesia.

“Dr. Septevani is an expert in the processing of waste to obtain new cellulosic materials, so the work came almost spontaneously, using cellulosic raw material of different sources to develop new waterborne resins,” Roppolo said. “Again, this study is only a step within the larger goal of sustainability of 3D printable materials.”

Natural hydrogels have truly remarkable properties, including high biocompatibility and biodegradability, as well as low toxicities. Currently, 3D printing processes heavily rely on synthetic materials that are not biodegradable and are based on fossil fuel-based resins.

This is primarily because many existing natural hydrogels have very poor mechanical properties, which makes them difficult to use for light-induced 3D printing. Roppolo and his colleagues have thus been trying to develop natural hydrogels with more desirable properties, which could help to make 3D printing more sustainable worldwide.

“The goal of our recent paper was to modify natural hydrogels to make them printable and to improve their mechanical properties so that one can take advantage of their characteristics, but at the same time to enable the fabrication of complex shapes,” Roppolo explained. “In our perspective, this will enable further development, especially for what regards drug delivery and development of cell scaffolds.”

Ultimately, Roppolo and his colleagues were able to adapt acrylated-carboxymethyl cellulose hydrogels to enhance their printability. To do this, they added biowaste-sourced cellulose nanocrystals (NCs) derived from palm oil to the hydrogels, to produce hybrid polymeric networks.

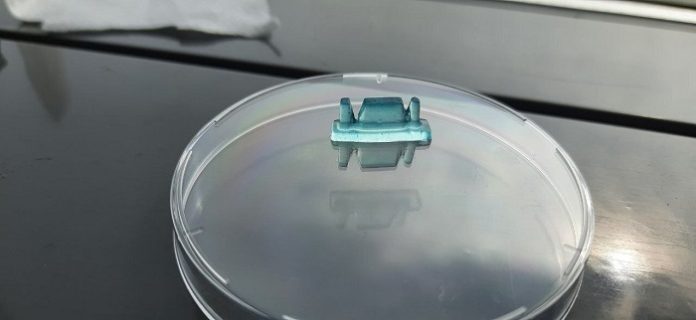

“From a material point of view, a great achievement of our work was to obtain resins with good printability, good shape fidelity, and with good mechanical properties, which make the 3D printed objects able to be manipulated easily by operators,” Roppolo said. “This is not trivial for these types of hydrogels.”

The hydrogels introduced by this team of researchers have numerous advantageous properties, including good printability, as well as controlled swelling and pH sensitivity. In the future, they could be used to create numerous devices using 3D printing, including sensors and soft robotic systems.

As the natural hydrogel inks are based on renewable materials, they open interesting possibilities for the use and valorization of residual waste derived from agriculture. The recent work by Roppolo and his colleagues could thus also inspire other teams to explore the potential of this residual waste in material science.

“We are currently working on several other projects aimed at obtaining printable materials from crop waste,” Roppolo added. “Our work will continue to explore two research streams: on the one hand the valorization of waste to produce 3D printable resin, on the other hand, their application in the bio-related field, for instance, patches for drug delivery or scaffolds to perform cellular studies.”