NANO Nuclear Energy Inc. is making significant strides in the nuclear energy sector, focusing on becoming a diversified and vertically integrated company. On July 18, the company successfully closed an additional sale of 135,000 common stock shares at $20.00 per share, marking a significant financial milestone. NANO Nuclear, recognized as the first publicly listed portable nuclear microreactor company in the U.S., according to its website, is dedicated to advancing sustainable energy solutions through four main business areas: portable microreactor technology, nuclear fuel fabrication, nuclear fuel transportation, and consulting services within the nuclear industry.

NANO Nuclear is led by a team of world-class nuclear engineers who are developing cutting-edge products like the ZEUS solid core battery reactor and the ODIN low-pressure coolant reactor. These cutting-edge nuclear microreactors are engineered to provide clean, portable, and on-demand energy solutions, effectively meeting both present and future energy demands.

In a recent interview, NANO Nuclear Energy’s CEO, James Walker, outlined the company’s ambitious plans to establish a vertically integrated nuclear fuel business through its subsidiaries, Advanced Fuel Transportation Inc. (AFT) and HALEU Energy Fuel Inc. (HEF). The goal is to secure a reliable supply chain for high-assay, low-enriched uranium (HALEU) fuel, which is crucial for advanced nuclear reactors. HALEU, enriched to contain 5-19.9% of the fissile isotope U-235, enhances reactor performance, allowing for smaller designs with higher power density. Recognizing these advantages, HEF is planning to invest in fabrication facilities to meet the growing demand for advanced reactor fuel.

AFT, a key subsidiary of NANO Nuclear, is led by former executives from the world’s largest transportation companies. The subsidiary aims to establish a North American transportation network to supply commercial quantities of fuel to small modular reactors, microreactor companies, national laboratories, the military, and Department of Energy (DoE) programs. AFT’s position is strengthened by its exclusive license for a patented high-capacity HALEU fuel transportation basket, developed in collaboration with three prominent U.S. national nuclear laboratories and funded by the DoE. Concurrently, HEF is dedicated to establishing a domestic HALEU fuel fabrication pipeline to cater to the expanding advanced nuclear reactor market.

Walker acknowledged several challenges that the company faces and outlined strategies to overcome them. One of the main challenges lies in navigating the intricate regulatory landscape. Obtaining numerous permits and licenses from bodies like the Nuclear Regulatory Commission (NRC) and the DoE is essential for nuclear fuel operations. To address this, NANO Nuclear plans to invest in a dedicated regulatory affairs team to manage the licensing process and ensure ongoing compliance with stringent safety and environmental standards. Early and consistent engagement with regulators will also be crucial to align operations with regulatory expectations.

Technical and engineering challenges are also a significant focus for NANO Nuclear. Walker emphasized the importance of developing and optimizing the deconversion process to safely and efficiently handle enriched uranium hexafluoride (UF6) and convert it into other uranium fuel forms. Meeting reactor specifications requires attaining the high precision and quality essential in HALEU fuel fabrication. To overcome these challenges, NANO Nuclear intends to leverage expertise from experienced nuclear engineers and collaborate with research institutions for technology development. Rigorous quality control systems and continuous improvement practices will be key components in addressing these technical hurdles.

Another set of challenges relates to supply chain and logistics. Given the stringent safety protocols required for handling radioactive materials, ensuring the secure and safe transport of HALEU fuel is of utmost importance. Walker noted the importance of synchronizing activities across multiple facilities to avoid bottlenecks and delays. To effectively manage the supply chain, NANO Nuclear intends to establish strong transportation and security protocols in collaboration with specialized logistics companies, along with implementing advanced tracking and coordination systems.

Economic and financial viability is another critical consideration. Building facilities for deconversion, fuel fabrication, and transportation demands significant capital investment. To ensure the economic viability of the integrated supply chain, managing operational costs is essential. Walker highlighted the need to secure a range of funding sources, such as government grants, private investments, and strategic partnerships. To support these efforts, NANO Nuclear will develop detailed financial models to forecast costs and revenues and implement cost-control measures.

Market and demand uncertainties also pose challenges for the company. It is crucial to secure adequate demand for HALEU fuel, especially from microreactor manufacturers and other potential clients. To tackle this, NANO Nuclear intends to carry out market research to identify and secure long-term contracts with key customers. By differentiating its product offerings through quality, reliability, and integrated services, the company aims to compete effectively with existing fuel suppliers and new market entrants.

Addressing human resources and expertise is equally important for NANO Nuclear’s success. Recruiting and retaining highly skilled personnel with expertise in nuclear technology, engineering, and regulatory compliance is critical. To this end, Walker mentioned that the company will develop a comprehensive human resources strategy focusing on recruitment, training, and career development to ensure the necessary talent is in place.

The company’s advancements in microreactor technology are particularly noteworthy. The latest advanced microreactors, with a thermal energy output ranging from 1 to 20 megawatts, provide a flexible and portable option compared to traditional nuclear reactors. Microreactors can generate clean and reliable electricity for commercial use while also supporting a range of non-electric applications, such as district heating, water desalination, and hydrogen fuel production.

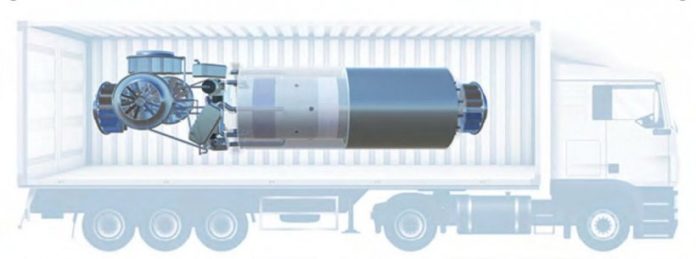

NANO Nuclear is at the forefront of this technology with its innovative ZEUS microreactor ZEUS boasts a distinctive design with a fully sealed core and a highly conductive moderator matrix for effective dissipation of fission energy. The entire core and power conversion system are housed within a single shipping container, making it easy to transport to remote locations. Engineered to deliver continuous power for a minimum of 10 years, ZEUS provides a dependable and clean energy solution for isolated areas, utilizing conventional materials to lower costs and expedite time to market.

The ZEUS microreactor’s completely sealed core design eliminates in-core fluids and associated components, significantly impacting overall system reliability and maintenance requirements. By reducing the number of components prone to failure, such as pumps, valves, and piping systems, the reactor’s design decreases the likelihood of mechanical failures and leaks, thereby enhancing overall reactor reliability. This inherently safer design also eliminates coolant loss scenarios, which are among the most severe types of reactor incidents.

With fewer moving parts, the maintenance intervals for ZEUS are significantly reduced. Components that avoid exposure to corrosive and erosive fluids have an extended service life, leading to fewer and less extensive maintenance activities. The absence of fluids simplifies inspections and replacements, making routine maintenance easier and quicker, ultimately reducing reactor downtime and operational costs.

Using an open-air Brayton cycle for power conversion in the ZEUS microreactor presents both significant benefits and challenges. The cycle’s high thermodynamic efficiency and mechanical robustness make it suitable for remote locations. By using air as the working fluid, the need for water is eliminated, reducing corrosion risk and making the reactor ideal for arid regions. However, challenges include managing high temperatures and ensuring material durability. Efficient heat exchanger design and advanced control systems are crucial, along with robust filtration and adaptable systems to handle dust and temperature extremes in remote areas.

The highly conductive moderator matrix in the ZEUS microreactor significantly enhances safety and efficiency in dissipating fission energy compared to traditional reactor designs. This advanced matrix ensures superior thermal conductivity, allowing for rapid and efficient heat transfer away from the reactor core. The matrix’s thermal properties also support passive cooling mechanisms, such as natural convection, that operate without external power, adding a critical safety layer during emergencies.

NANO Nuclear is also developing the ODIN advanced nuclear reactor to diversify its technology portfolio. The ODIN design will use conventional fuel with up to 20% enrichment, minimizing development and testing costs With its low-pressure coolant system, the design improves structural reliability and extends service life. ODIN’s high-temperature operation ensures resilient performance and high-power conversion efficiency. Utilizing natural convection for heat transfer and decay heat removal, it offers robust safety features that align with the company’s commitment to advancing nuclear technology.

In summary, NANO Nuclear Energy Inc. is pioneering advancements in nuclear energy through its focus on portable microreactor technology and a vertically integrated supply chain. The company’s innovative ZEUS and ODIN reactors, along with its strategic approach to addressing regulatory, technical, and market challenges, position it as a key player in the future of sustainable energy solutions.