Courtesy: Microchip

Silicon Carbide (SiC) Schottky Barrier Diodes (SBDs) increase efficiency and ruggedness to help create faster and more reliable applications.

Better Efficiency and Reliability Through Silicon Carbide

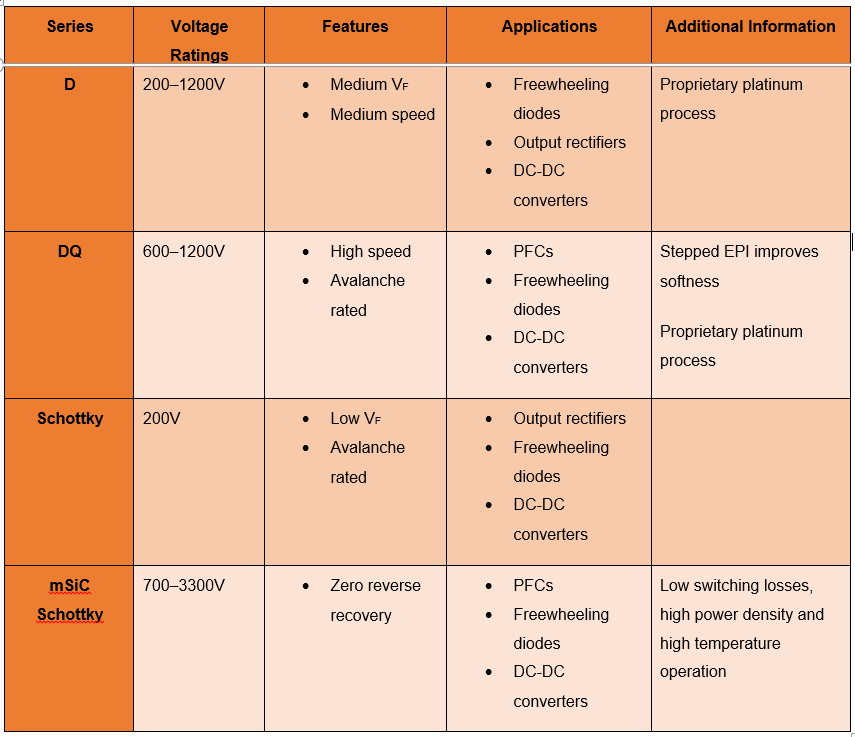

Silicon Carbide (SiC) Schottky Barrier Diodes (SBDs) increase efficiency and create reliable high-voltage applications. Our rich history and experience allow us to deliver highly reliable SBDs that are designed with high repetitive Unclamped Inductive Switching (UIS) capability at a rated current, which exhibits no degradation. Our mSiC diodes are designed with balanced surge current, forward voltage, thermal resistance and thermal capacitance ratings at low reverse current for lower switching loss to create more efficient power systems.

Because of differences in material properties between SiC and silicon, silicon Schottky diodes are limited to a lower voltage range with higher on-state resistance (RDS(on)) and leakage current. However, SiC Schottky diodes can obtain a much higher breakdown voltage while maintaining low on-resistance and low switching losses, improving ruggedness over traditional silicon Schottky diodes. Our portfolio of mSiC products covers 700V, 1200V, 1700V and 3300V (3.3 kV) SiC Schottky diodes.

In summary, SiC offers the following advantages over silicon:

- Better reverse current capability

- Higher temperature stability

- Higher radiation resistance

Breakdown Voltage

The breakdown voltage of a diode is the voltage at which the diode breaks down and starts conducting current. The breakdown voltage determines the maximum voltage that the diode can withstand before it fails. SiC SBDs exhibit higher breakdown voltages than silicon diodes because of the SiC material’s higher bandgap. This higher breakdown voltage rating allows SiC diodes to withstand higher voltages without damage.

The higher breakdown voltage of SiC diodes is important for several applications including power converters, inverters and motor drives. In these applications, the diodes are often exposed to high voltages. The higher breakdown voltage of SiC diodes allows them to withstand these high voltages without damage, which can lead to improved reliability and performance.

Forward Voltage Drop

The forward voltage drop of a diode is the voltage drop that occurs when the diode is conducting current. This parameter determines the efficiency of the diode. SiC diodes have a lower forward voltage drop than silicon diodes. The higher bandgap means it takes less energy for an electron to move through the material. This lower forward voltage drop allows SiC diodes to be more efficient than silicon.

The lower forward voltage drop is important for several applications including power converters, inverters and motor drives. In these applications, the diodes are often used to convert power from one form to another. The lower forward voltage drop of SiC diodes allows them to be more efficient in these applications, which can lead to reduced costs and improved performance.

Reverse Recovery

Reverse recovery is a phenomenon that occurs when a diode is switched from conducting current to non-conducting current. During reverse recovery, a small amount of current flows in the reverse direction. This current can cause a voltage drop across the diode, which can damage the diode if it is not properly managed.

SiC diodes have a much shorter reverse recovery time, allowing them to switch from conducting current to non-conducting current more quickly, which can reduce the risk of damage. Reverse recovery is an important consideration for any application that uses diodes.

Reverse Current

The reverse current of a diode is the current that flows in the reverse direction when the diode is biased in the reverse direction. This current is a major factor that limits the performance of SiC diodes in high-voltage applications. The reverse current of SiC diodes is typically much higher than that of silicon diodes because the SiC material has a higher bandgap, which causes it to take more energy to break an electron free from its atom. This higher bandgap also means that there are fewer free electrons available to carry current in the reverse direction.

High reverse current can cause several problems in high-voltage applications, causing the diode to overheat and fail. It can also cause the diode to emit noise and interference. There are a few ways to reduce the reverse current of SiC diodes. One way is to use a diode with a higher breakdown voltage. Another way is to use a diode with a lower doping level. However, these techniques can reduce the performance of the diode in other ways.

High Temperature and High Current Stability

High temperature and high current stability are crucial because SiC diodes are often used in a variety of applications that require high currents and temperatures of up to 150°C. The stability of SiC diodes is important for their use in applications with more demanding conditions.

Stability at high temperatures and currents is due to the higher bandgap, which makes SiC more resistant to damage from heat and high current conditions. SiC diodes have a lower concentration of impurities than silicon diodes, making SiC diodes less likely to experience recombination, the process by which an electron and a hole combine to form an atom. Recombination can cause the diode to lose its ability to conduct current, leading to failure.

These attributes make SiC diodes well suited for applications that require high temperatures and currents, such as power converters and inverters, leading to improved reliability and performance in the end equipment.

Start Designing with SiC

Getting started with designing with Silicon Carbide (SiC) involves understanding its benefits and applications. We offer a range of Silicon Carbide (SiC) power products which are the key to faster, more efficient energy solutions.