All-perovskite tandem solar cells, solar cells comprised of stacked wide-bandgap (WBG) and narrow-bandgap (NBG) perovskites, could be particularly promising energy solutions. Compared to other existing photovoltaic systems, these cells could achieve good energy efficiencies while significantly lowering fabrication costs.

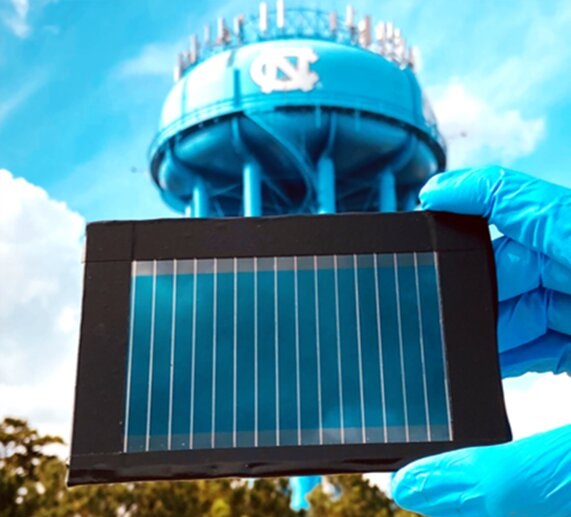

Researchers at the University of North Carolina at Chapell Hill and the University of Rochester have recently devised a new hot gas-assisted method that could improve the fabrication of NBG perovskite films for tandem solar cells. This strategy combined with an anti-oxidation material added in the film, both of which were introduced could increase the solar cells’ carrier recombination lifetime (i.e., the time it takes for excess charge carriers to decay).

“All-perovskite tandem perovskite solar cells are promising to reduce the cost of photovoltaic systems, due to their potential to reach a much higher efficiency than their single-junction counterparts, while maintaining the solution fabrication processes,” Jinsong Huang, one of the researchers who carried out the study. “Also, compared to single junction perovskite modules, the application of tandem structures, which have much smaller photocurrents but higher photovoltage, can also reduce the cell-to-module efficiency derate, and thus enable the realization of higher module efficiencies for monolithically interconnected modules in a series.”

In all-perovskite tandem solar cells, both the WBG and NBG perovskite layers are deposited using a method called blade coating. Blade coating, also known as knife coating or doctor blading, is a scalable coating technique that entails applying an excess of coating material to a substrate and then removing some using a blade until one reaches the desired coating.

Huang and his colleagues devised a new blade coating strategy that could be particularly favorable for the fabrication of NBG perovskite films. In contrast with other typically employed strategies, their technique utilizes a hot gas.

“To create our NBG perovskite films, we developed a hot gas-assisted blade coating strategy to achieve high-quality, large-area, and thick films,” Huang said. “The hot gas accelerated the drying of the high boiling point solvents to solidify the as-coated wet film, preventing the microscale solution flows. In addition, a reducing agent benzylhydrazine hydrochloride (BHC) was introduced to prevent Sn2+ and iodide oxidization during film deposition and, more importantly, to withstand the air exposure during module fabrication.”

Using their new blade coating method, Huang and his colleagues were able to suppress unfavorable processes occurring during the coating of their NBG perovskite film. The resulting film was then used to create all-perovskite tandem solar cells with remarkable efficiency of 21.6%, with a 14.3 cm2 aperture area, which corresponded to an active area efficiency of 23%.

“Our innovative hot-gas assisted blade coating method enables the high-throughput fabrication of large area, high-quality NBG films for all-perovskite tandem solar cells,” Huang added. “On the other hand, scaling up all-perovskite tandem solar modules is challenging due to the degradation of the narrow band gap subcell during module processing in an ambient condition. In this work, the reducing agent BHC enables module fabrication in an ambient environment, which is a critical step toward industrialization.”

In the future, the recent work by this team of researchers could contribute to the industrialization and up-scaling of efficient all-perovskite tandem solar cells that are more affordable. Meanwhile, the researchers plan to use their method to develop more efficient and stable solar modules with larger surface areas.