Gurpreet Sandhu | Vice President | Platform Engineering Group

Reshma PP | Director System Design | Platform Engineering Group

Roberta Zouain | Sustainability Product Strategy & Marketing Manager | Client Segments

In the increasingly digital world, e-waste is a growing problem. Every year, over 60+ Million tons of e-waste is generated with less than 25% collected. Less than 12% of e-waste is recycled with over 85% being burnt, causing harmful pollution and environmental poisoning. Computers contribute to a significant portion, almost 70%, of e-waste. It is also a significant source of potential business with over $65 billion dollars of materials and minerals that could potentially be recovered from landfills.

With low recovery and repair rates, consumer activists and environmental groups worldwide have been actively lobbying for the right-to-repair. The movement has gained significant momentum in recent years, with increasing support from both corporations and governments.

The right-to-repair emphasizes the importance of being able to fix and upgrade PCs on one’s own. Improving repairability requires fundamental changes starting from the design methodology. Compliant devices will need to guarantee, by design, repairability and upgradability.

This approach requires a modular PC architecture which is deviant from the current monolithic approach. Modular PC architecture is an innovative approach that addresses this requirement of end-of-life extension with the flexibility to upgrade and repair their systems with ease.

Modularity can be approached at three levels depending on manufacturers’ product positioning, market dynamics, costs, and other factors.

- Factory Modularity is a level of modularity that can only be exercised at the factory. For example, whilst ordering a car the manufacturer provides different choices of engines. Depending on what the user decides, the factory fits the car with the requested engine. This level of modularity can only be exercised at factory setups hence the name. This level of modularity provides for flexibility and high levels of design reuse and hence lower costs, manufacturing carbon footprint and scalability benefits.

- Field Modularity is the next level of modularity that provides for field-level changes but does not require a factory setup, yet might still require skilled labor and a specialized tools to make the necessary upgrades or changes. For example, quite a few cars provide different tire sizes as options. When a customer decides on a specific set of tires, sizes, and wheelsets, the dealer – not the factory – gets involved. The cars are still manufactured with the standard set of wheels but based on customer requests the end dealer swaps the factory-fitted wheels with custom ones. These changes still require a field specialty setup but can be done effectively outside of the factory setup.

- User Modularity is the last level of modularity that allows the end user to change the settings or components within a product at will at the convenience of their home or office. Good examples are WiFi dongles, user upgradable memory and storage, etc. These provide the ultimate level of modularity to the end user, do not require the intervention of the dealer or the manufacturer, and can be done using standard tools by the user anytime during the effective lifetime of the product.

To enable these modularity concepts, a deviation in the current PC architecture is needed. This paper explores the transformative potential of such modular PC architectures.

Modular PC design goals and motivation

Modular PC architecture breaks from the traditional all-in-one motherboard design, opting instead for a system where key components are categorized into individual, interchangeable modules. This innovative structure allows for targeted upgrades, repairs, and replacements, significantly extending the device’s lifespan and reducing electronic waste.

The goals of modular PC design are

- Reduce the environmental impact by minimizing carbon footprint

- Create scalable systems that can evolve with changing user requirements & interests

- Supports the right-to-repair with field-replaceable components

- Make seamless system upgrades possible, avoiding complete device turnover

- Enable cost-optimized products by streamlining manufacturing design processes (module reuse)

- Easier product SKU management and faster time to market

Intel has been at the forefront, consistently leading the way in establishing industry standards, driving technological innovation, and working on ecosystem enabling and shaping the future of technology. We actively invest resources to foster advancements in sustainable design. Our focus is on creating end products that not only push the boundaries of innovation but also prioritize repairability and reusability, reflecting our dedication to environmental responsibility.

The landscape of technology is diverse, with each market segment presenting its own unique set of requirements and challenges. Intel understands that a one-size-fits-all approach does not suffice in addressing the nuanced demands of these varied segments. Therefore, we are tailoring our strategies and solutions to meet the specific needs of each sector, ensuring that our innovations are both relevant and impactful across the entire spectrum of the technology industry. To this end, we have created three different proposals to suit the needs of each segment.

Key Features of Modular PC Architecture

Notebooks and desktops equipped with configurable and upgradeable components, such as RAM, WiFi, and SSDs, can be easily updated to enhance system performance while retaining the same chassis. In addition to easier repairs, this approach can also result in fewer total SKUs that need to be designed, validated, and inventoried, helping manufacturers streamline product portfolio management.

Premium Modular PC Architecture

- Scalable Design with Reduced Engineering Efforts: Our three-board system maximizes PCB Panel utilization, curtails PCB waste, and accommodates diverse system configurations with minimal modifications.

- Ease of Upgrades: With standardized modules like M.2 SSDs and Core Board, users can effortlessly enhance their storage, and upgrade the system with next-generation SOC.

- Simplified Repairs: Our modular design streamlines the repair process and contributes to the right-to-repair initiative allowing for the replacement of specific damaged parts and IO without the need to discard the entire motherboard.

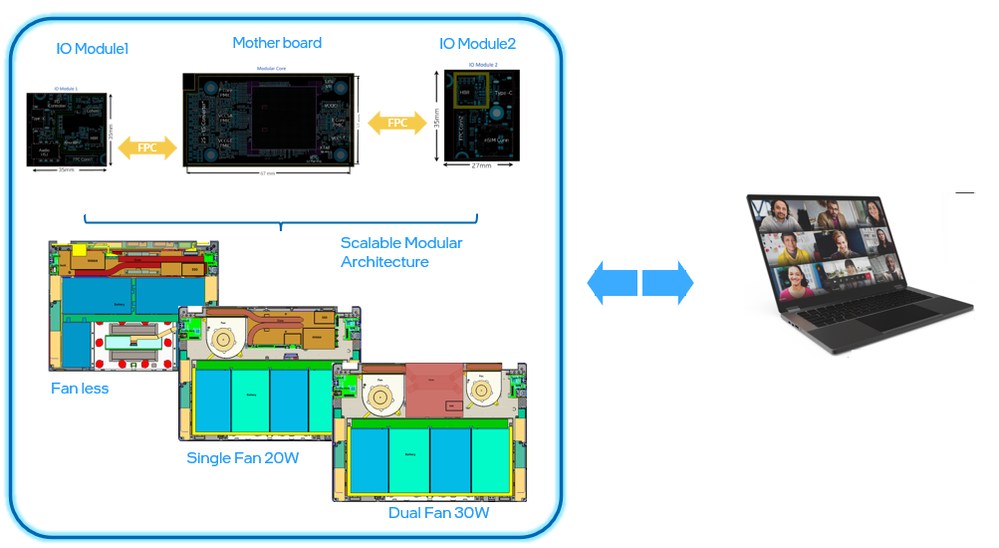

The creation of universal I/O boards (left and right I/O boards) that can be utilized across various platforms or market segments leads to cost savings by streamlining the duration of the design cycle and minimizing the engineering investment required. The I/O boards for Premium Modular designs are engineered to be common between the fan-less Thin & Light system, which operates within a 10W power envelope, and the premium fanned designs, which function within a 20W (single fan) and 30W (dual fan, WiFi only SKU) power envelope. This commonality allows for greater flexibility and efficiency in the design and manufacturing process across both fan and fanless systems. The I/O port capabilities of the 10W fanless and 30W fanned systems are identical and can be reused. The Premium Modular designs exemplify sustainability with an improved modular and scalable board architecture that includes a compact core and reusable I/O modules that can be used across different SoC generations, as depicted in the figure below.

Although three segments have different system constraints with different system floorplans, which makes it challenging to have a common I/O board across segments, the common I/O board between the fan and fan less systems have been designed to address all these challenges. The I/O boards are designed in such a way that they can be reused across consumer and commercial segments.

Entry/Mainstream Modular PC Architecture

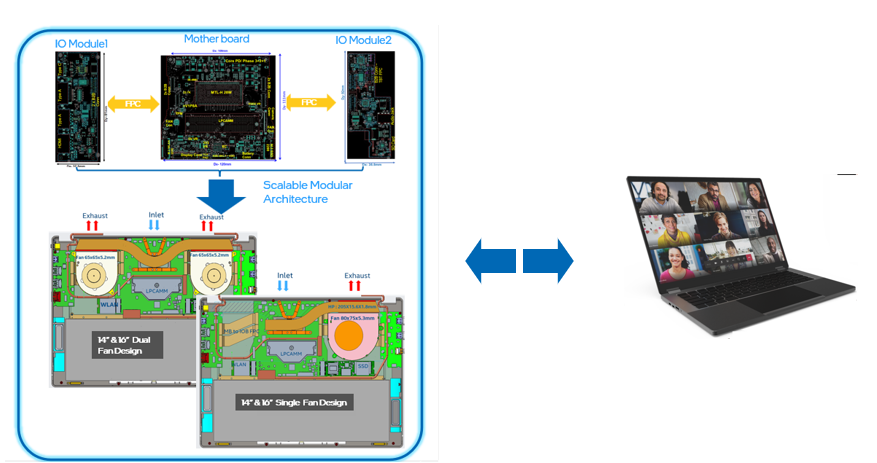

- Scalable design with reduced engineering effort: Multi-generation Silicon to achieve cost neutrality. IO cards can be reused across segments within a platform. Redesign the IO cards to get multiple SKUs of the design. Seamless scaling of 14-16″ screen size, single Fan to dual fan thermal solution

- Ease of Upgrades: Upgradable core, LPCAMM Memory, WiFi & SSD

- Simplified Repair: Individually repairable IO boards, Thunderbolt Technology Modules

Scalable Modular system design with modular LPCAMM Memory, M.2 Storage and WiFi. Type 3 8L Standard Loss PCB with BOM cost-optimized design catering to the mainstream segment designs targeting multiple form factors and screen sizes.

Desktop Modular PC Architecture

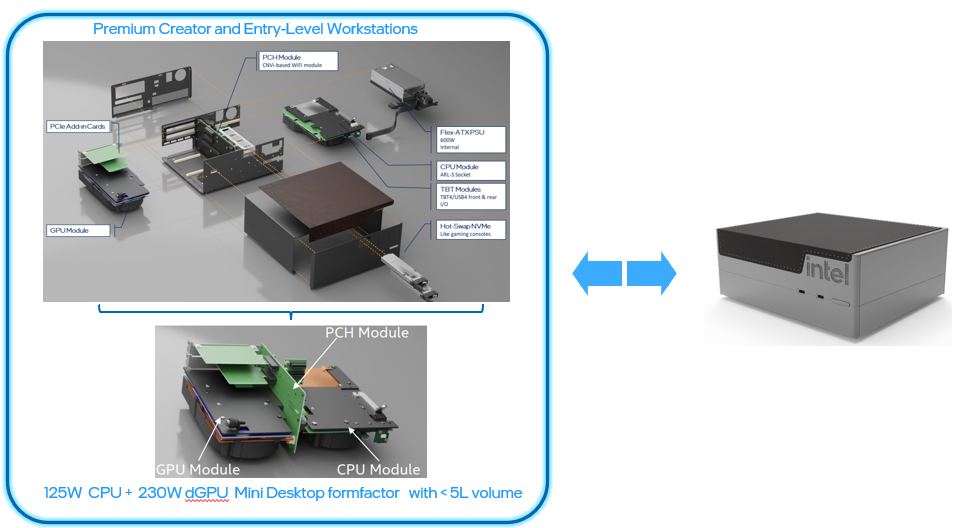

- Modular designs: Industrial design was created to provide the ideal experience for users with a focus on usability, repairability and serviceability.

- Ease of Upgrades: Removable CPU, SODIMM memory, and GPU (Graphic Processing Unit) using slide rails, along with hot-swappable storage.

- Simplified Repair: Highly Modular and Repairable Memory, PCH (Platform Controller Hub), GPU, and Thunderbolt Modules on a high-density 5L Chassis

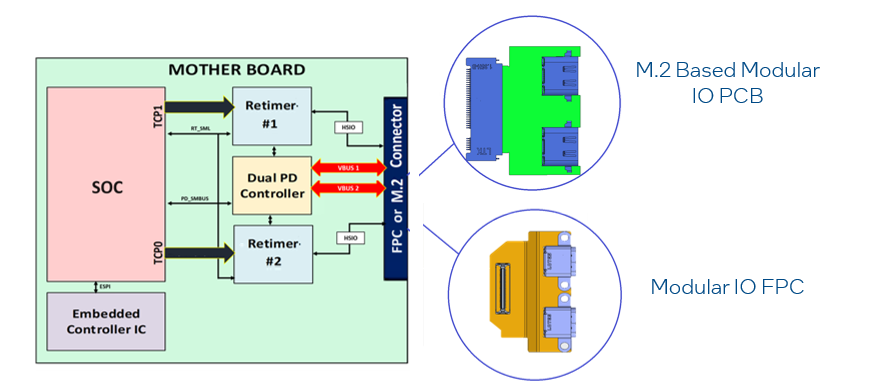

Intel designs are elevating modularity to the next level by introducing subsystem-level replaceable modules, such as a Type-C connector on an FPC (Flexible Printed Circuit) and a Type-C connector on an M.2 PCB. These modules significantly reduce repair costs and simplify the repair process in the event of port or connector damage at the end-user level.

Subsystem-level Modularity: Type-C on FPC, Type-C on PCB

Thunderbolt Technology using a Type-C connector is a high-speed versatile interconnect with multiple end device options along with a power source to the system. Type-C connectors due to their delicate structure have been reported to get damaged more often than other IO ports. The Thunderbolt post-channel modularity technology is a possible solution for addressing this repairability issue by adding the next level of modularity.

Conclusion: Intel has long been recognized as a leader in the technology sector, with a storied history of setting industry benchmarks and driving innovation. Our legacy is built on a foundation of pioneering microprocessor advancements and shaping the digital landscape. As we continue to lead the way, our focus has shifted towards integrating sustainability into the core of our product design and business philosophy. Our latest proposal for a modular PC architecture is a testament to this enduring commitment. By developing a new approach to system design that allows for easy upgrades and component replacements, we aim to significantly extend the usable life of computing devices, thereby reducing electronic waste and promoting a more sustainable consumption model. By working closely with our customers and partners, we hope to transform the way PCs are designed and help shape the future of computing.