The Micro-Measurements brand of Vishay Precision Group , industry innovators in the design, development and manufacture of resistive-foil sensors for high-precision strain measurements, on March 28, 2017, announced the global market introduction of a new line of free-filament wire strain gages and ceramic cements, expressly designed for extreme high-temperature environments.

The new free-filament wire strain gages allow for high-reliability measurements of both dynamic and limited-static strain, at much higher temperatures than have been traditionally possible with conventional bonded strain gage designs. The gages, offered as the ZWH-, ZWN-, and ZWP-Series, can accurately measure dynamic strain values in temperatures up to +1900°F (+1038°C), as well as limited-static strain to +1500°F (+816°C). They offer excellent oxidation resistance, along with improved bond strength, as compared to traditional free-filament foil gage designs.

Each series offers unique application advantages, depending upon specified parameters. In applications where a compensating grid is used to achieve limited static strain measurements, for example, the iron-chrome-aluminum alloy ZWH-Series is recommended. In applications where optimal fatigue life is desired, the Nichrome-V alloy ZWN-Series is typically specified. And finally, where requirements call for a combination of highest possible oxidation resistance and highest temperature measurement capabilities, the platinum-tungsten alloy ZWP-Series is recommended.

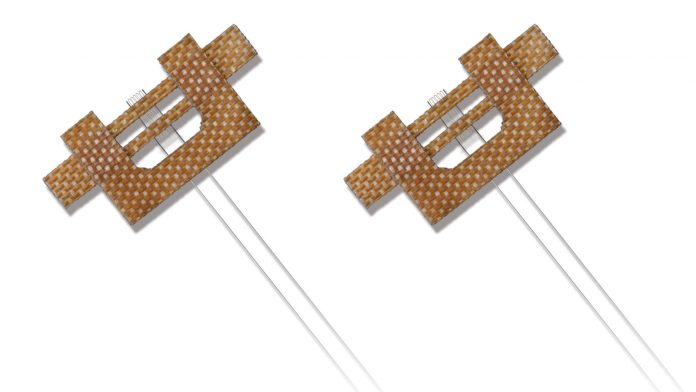

All Micro-Measurements ZWH-, ZWN-, and ZWP-Series gages are RoHS compliant and feature a free-filament wire construction, along with a series of integrated, welded 0.003-inch (0.076 mm) diameter lead wires. A high-fatigue wire (Option Z) is available upon request. The gages offer 120-ohm resistance and are packaged with a fiberglass reinforced segmented tape carrier, which holds the grid and lead patterns intact during installation.

They are bonded using either ceramic cement or Roxide flame spray. Among the new Micro-Measurements high-temperature ceramic cement offerings are the WC-16, NCC-3, and HG-1. The WC-16 ceramic cement offers best compatibility with new ZWP-Series free-filament wire gages, while the NCC-3 offers an environmentally friendly and RoHS compliant alternative to ceramic cements containing hexavalent chrome. The HG-1 ceramic cement offers high-performance bonding with steel and superalloys.

Recommended accessories for the new ZWH-, ZWN-, and ZWP-Series include the Model 700 welder and hand-welding attachment, both available from Micro-Measurements, for ease of cable welding to gage leads. Typical applications for the Series include extreme high-temperature strain measurements in chemical plants, power plants and nuclear environments, as well as the testing of gas turbine engine blades and components, automotive exhaust and transmission systems, in-chamber environmental testing, and spacecraft propulsion systems. For more information on these and other stress and strain gage sensing technologies from Micro-Measurements, visit www.micro-measurements.com.