The advancement of three-dimensional integrated circuits (3DICs) offers substantial performance enhancements by consolidating more functionality into compact designs. However, this innovation also brings significant challenges, particularly in managing the increased heat dissipation.

The Benefits and Obstacles of 3DICs

3DIC technology entails layering several silicon wafers or dies and linking them through vertical interconnects. This stacking provides several advantages:

- Enhanced Performance: Reducing the distance between components minimizes signal delays, accelerating processing speeds.

- Increased Functionality: Multiple functionalities can be integrated into a single compact package, leading to more versatile devices.

- Lower Power Consumption: Shorter interconnects can result in reduced power consumption compared to traditional 2D ICs.

Despite these benefits, 3DICs face challenges, with thermal management being a primary concern. The increased component density can result in elevated temperatures, which may affect the performance and reliability of the device.

Why Effective Thermal Management Matters

Thermal management in 3DICs is complex due to factors such as:

- High Power Density: The close arrangement of components generates significant heat.

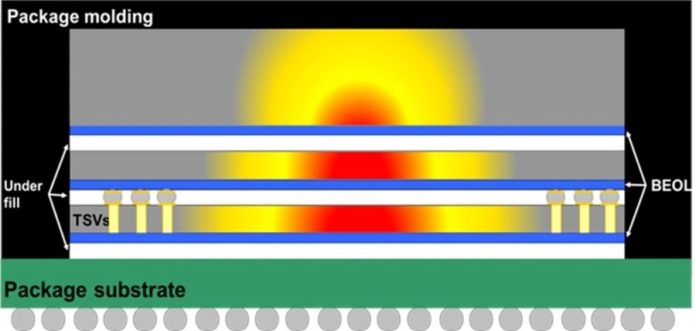

- Thermal Gradients: Uneven power distribution can create varying temperatures across the chip.

- Thermal Resistance: Stacked, thinned dies increase resistance to heat dissipation.

Inadequate thermal management can lead to performance degradation, reduced reliability, and shorter device lifespans. Therefore, thorough thermal analysis is critical throughout the design process.

The Importance of Early-Stage Thermal Analysis

Historically, thermal analysis was conducted at the package and system levels, separate from IC design. However, with the advent of 3DICs, early-stage thermal analysis at the die level is crucial. This approach helps:

- Identify Hotspots: Early detection of high thermal activity areas enables design adjustments to improve heat distribution.

- Optimize Design: Iterative analysis during die and package design enhances thermal performance.

- Improve Reliability: Addressing thermal issues early boosts overall product reliability and reduces failure risks.

Advancements in Die-Level Thermal Analysis

Emerging integrated chip-package thermal co-design tools are vital for addressing 3DIC thermal challenges. These tools offer:

- IC Design Integration: Integration with existing IC design tools ensures thermal analysis is part of the design process.

- Precision and Detail: Sophisticated solvers deliver comprehensive thermal analysis for the 3DIC assembly.

- Automated Simulation: Automation makes thermal analysis accessible to designers without specialized expertise.

- Iterative Analysis: Continuous refinement based on thermal feedback is facilitated.

Integrated Thermal Analysis Solutions

An example of an effective thermal analysis tool is one that includes a custom 3D solver within a well-established IC design platform. This tool supports various 3D integration technologies and allows for comprehensive thermal assessment from initial design to final approval. It is integrated with other design tools across IC, package, and system levels.

Utilizing Thermal Analysis Throughout the Design Process

An effective thermal analysis tool should be capable of supporting multiple phases of the design process:

- Early Design Planning: High-level power estimates guide thermal impact exploration, including 3D partitioning and package selection.

- Detailed Design: Thermal analysis verifies that designs remain within thermal limits, focusing on power maps and hotspot effects.

- Design Signoff: Comprehensive verification ensures the design meets thermal and reliability requirements.

- Package-System Integration: IC-level thermal models aid in package and system thermal analysis, streamlining the development process.

Practical Integration and Usability

Effective thermal analysis tools should be user-friendly, incorporating automation features such as:

- Optimized Gridding: Finer grids in critical areas for accuracy and coarser grids elsewhere for efficiency.

- Time Step Automation: Automatic generation of smaller time steps during power transitions.

- Equivalent Thermal Properties: Simplifying models while maintaining accuracy.

- Power Map Compression: Adaptive bin sizes to capture non-uniform power distribution.

- Automated Reporting: Summary reports that highlight key results for decision-making.

Visualization and Debugging

Advanced visualization tools are crucial for interpreting results and debugging. Features may include:

- Overlaying Thermal Maps: Visualizing power distribution and thermal behaviour in the context of the layout.

- Multiple Colormap Displays: Viewing thermal distributions across 3D components with animation capabilities.

- Waveform Viewing: Integrating temperature and power waveforms with measured results for calibration.

Real-World Applications and Case Studies

The benefits of integrated thermal analysis solutions are demonstrated in real-world scenarios. For instance, CEA utilized an advanced tool from Siemens EDA to study their 3DNoC demonstrator, achieving high accuracy with minimal differences between simulated and measured data. Additionally, thermal-aware partitioning and optimization in complex designs involving multiple chiplets demonstrated significant improvements in thermal management.

Conclusion

The shift to 3DICs represents a major advancement in semiconductor design, offering enhanced performance and functionality. Addressing the associated thermal challenges requires robust thermal analysis tools. By incorporating early-stage thermal analysis, designers can ensure their 3DICs meet performance and reliability standards, paving the way for the next generation of high-performance electronic devices.