Researchers have designed a fuel production system that uses water, carbon dioxide (CO2), and sunlight to produce aviation fuel. They have implemented the system in the field, and the design could help the aviation industry become carbon neutral.

“We are the first to demonstrate the entire thermochemical process chain from water and CO2 to kerosene in a fully-integrated solar tower system,” says Aldo Steinfeld, a professor. Previous attempts to produce aviation fuels through the use of solar energy have mostly been performed in the laboratory.

The aviation sector is responsible for about 5% of global anthropogenic emissions causing climate change. It relies heavily on kerosene, or jet fuel, which is a liquid hydrocarbon fuel typically derived from crude oil. Currently, no clean alternative is available to power long-haul commercial flights on a global scale.

“With our solar technology, we have shown that we can produce synthetic kerosene from water and CO2 instead of deriving it from fossil fuels. The amount of CO2 emitted during kerosene combustion in a jet engine equals that consumed during its production in the solar plant,” Steinfeld says. “That makes the fuel carbon neutral, especially if we use CO2 captured directly from the air as an ingredient, hopefully in the not-too-distant future.”

As a part of the European Union’s SUN-to-LIQUID project, Steinfeld and his colleagues have developed a system that uses solar energy to produce drop-in fuels, which are synthetic alternatives to fossil-derived fuels such as kerosene and diesel. The solar-made kerosene is fully compatible with the existing aviation infrastructure for fuel storage, distribution, and end use in jet engines, Steinfeld says. It can also be blended with fossil-derived kerosene, he adds.

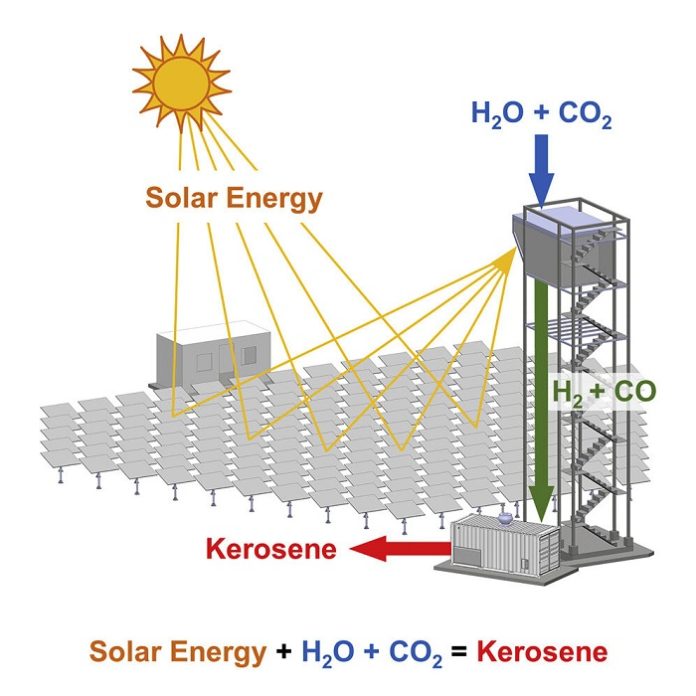

In 2017, the team started scaling up the design and built a solar fuel-production plant at IMDEA Energy Institute in Spain. The plant consists of 169 sun-tracking reflective panels that redirect and concentrate solar radiation into a solar reactor mounted on top of a tower. The concentrated solar energy then drives oxidation-reduction (redox) reaction cycles in the solar reactor, which contains a porous structure made of ceria. The ceria—which is not consumed but can be used over and over—converts water and CO2 injected into the reactor into syngas, a tailored mixture of hydrogen and carbon monoxide. Subsequently, syngas is sent into a gas-to-liquid converter, where it is finally processed into liquid hydrocarbon fuels that include kerosene and diesel.

“This solar tower fuel plant was operated with a setup relevant to industrial implementation, setting a technological milestone towards the production of sustainable aviation fuels,” Steinfeld says.

During a nine-day run of the plant, the solar reactor’s energy efficiency—the portion of solar energy input that is converted into the energy content of the syngas produced—was around 4%. Steinfeld says his team is working intensively on improving the design to increase the efficiency to values over 15%. For example, they are exploring ways to optimize the ceria structure for absorbing solar radiation and developing methods to recover the heat released during the redox cycles.