In the previous blog in this series, we saw that superior sensing modalities and compute power give Autonomous Mobile Robots (AMRs) an advantage over Automated Guided Vehicles (AGVs) when navigating dynamic environments. Today we are going to talk about why that is the case.

Localization is the process of determining where a robot is located within its environment. For mobile robots, the ability to map its surroundings and identify its position relative to that map are key. With greater localization awareness, tasks can be performed faster and more efficiently, as the majority of a mobile robot’s tasks involve moving from one location to another. It is this freedom of movement that gives AMRs independence within a factory, but how does it work?

Introduction to Inertial Measurement Units (IMUs)

Inertial Measurement Units (IMUs) provide crucial motion data for precise robot positioning. Integrated accelerometers measure acceleration with respect to the earth’s gravitational field, gyroscopes measure the rate of rotation providing angular velocity, and magnetometers support accurate orientation estimation in challenging environments. By integrating all three of these advanced sensing technologies, IMUs enable robots to precisely determine their orientation, position, and movement.

Let’s consider the challenges for localization and how IMUs overcome these.

Dead Reckoning: A navigation technique to estimate current position based on a previously known position. By constantly providing data on position, orientation, and speed over elapsed time, IMUs enable precise estimation, contributing to reliable navigation for AMRs.

Robustness: Environmental factors can have a significant impact on sensor performance. Lidar sensors, for instance, may exhibit sensitivity to ambient light, dust, fog, and rain, resulting in decreased sensor data quality and potential disruptions in performance. Other sensor modalities, such as cameras, may encounter challenges from reflective surfaces and dynamic obstacles like other AMRs or workers. In contrast, IMUs demonstrate robustness across diverse conditions, including environments with electromagnetic interference, enabling them to operate effectively both indoors and outdoors. This adaptability makes IMUs an optimal choice for mobile robots, ensuring consistent performance in the face of environmental complexities.

Enhanced Reliability: IMUs stand out by providing high-fidelity positional output of up to 4kHz raw data. Other perception sensors are typically limited to update rates of ~10Hz to 30Hz. This increased update rate enhances reliability of IMU performance, especially in dynamic environments, enabling AMRs to estimate their position quickly and accurately in the short time between other measurements.

IMUs Versus Visual Odometry

You might be wondering, with the advancement in vision systems, why is the IMU still playing such a pivotal role in mobile robotics? Here’s why:

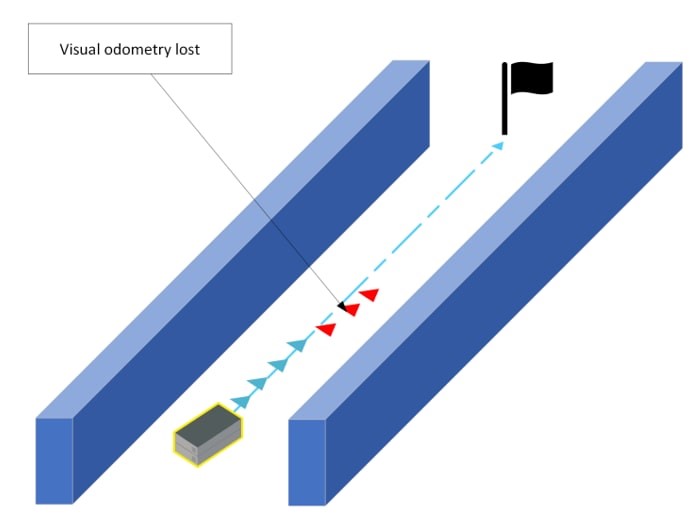

SLAM (Simultaneous Localization and Mapping) algorithms match observed sensor data with stored data to localize within the map. But what happens when observed sensor data is limited, for example in a long corridor with straight walls of uniform color, texture, or reflectivity? SLAM algorithms can struggle to localize precisely in such environments, and the AMR is likely to lose its position quickly due to a lack of distinctive features.

IMUs act as a valuable guidance system by providing heading and orientation information in feature-sparse environments such as corridors. They provide high short-term accuracy and immediate measurements between vision sensor measurements. IMUs have lower computational needs than visual odometry, enhancing redundancy and further endorsing them for AMR operations.

IMUs: Part of a Holistic AMR Design

While IMUs offer many benefits over other sensors, they can also be prone to drift. In situations where the environment is constantly changing, it may be advantageous for AMR operations to rely on multiple sensor inputs. This allows each sensor to overcome the limitations of the others for greater success. The next blog of the series will explore how this sensor fusion works and the combined benefit it brings to robotics.

Factories of the future may be purpose built and optimized for AMRs to operate in, but adapting these robots to existing warehouses and factories presents challenges.