MB Dynamics, Inc. field-proven industry experts in the design, manufacture and supply of vibration test systems and equipment, including buzz, squeak and rattle (BSR), steering, and suspension component test systems; modal exciters and amplifiers; automated calibration systems; dynamic controllers; transducer calibration systems; and test engineering services, announced the global market launch of its “4-in-1” multi device-under-test (DUT) automated accelerometer calibration system (“4-in-1” MDAC).

The “4-in-1” MDAC facilitates simultaneous and accurate calibrations of up to four piezoelectric (charge or PE), IEPE (low-impedance voltage mode), or variable capacitive (VC) accelerometers (DUT’s), of the same model and type, each weighing up to 20 grams, over frequencies from 1 Hz to 4000 Hz. The “4-in-1” MDAC can additionally perform automated single-DUT calibrations of PE, IEPE, velocity, piezoresistive and VC accelerometers, as well as vibration sensors and transducers, over frequencies from 1 Hz to 10 kHz, utilizing MB Dynamics’ own CAL50 calibration vibration exciter.

The automated multi-DUT capabilities afforded by the “4-in-1” MDAC helps calibration technicians to effectively enhance productivity, reduce measurement uncertainty, and mitigate risks of operator error, by significantly reducing the amount of time required to calibrate multiple accelerometers within a single protocol.

System automation afforded by the “4-in-1” MDAC is further supported by MB Dynamics’ own proprietary Win475 software, along with an industry standard NI DAQ card. The software facilitates both single- and multi-DUT accelerometer sine calibrations with full NIST traceability and FFT processing at specified frequencies. It further allows for automated storage and retrieval of accelerometer data, test specifications, and calibration results. The software control afforded by the “4-in-1” MDAC virtually eliminates operator error by ensuring repeatability, optimal signal-to-noise ratio and reduced measurement uncertainty. It further removes operator adjustment requirements for gain, vibration levels, or other parameters. End-users also have the option of utilizing MB Dynamics’ own highly experienced software engineering services team to integrate “4-in-1” MDAC data exports into a customer-specified database.

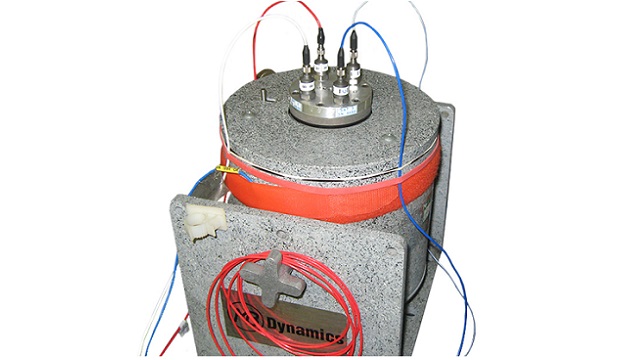

The associated hardware components of each “4-in-1” MDAC turnkey calibration system include five internal reference accelerometers (REFs), each with 100/mV sensitivity and weighing less than 20 grams, mounted inside of the CAL50. REFs are fully traceable to national standards and ISO 17025. The system also features both a single- and multi-DUT Expanded System Uncertainty (ESU) of ±1.2% at 100 Hz (minimum 3 mV signal), estimated in accordance with the ISO 16063-21 standard, and includes two Test Instrument Mounting Fixtures: one four-DUT and one single-DUT, each with a useable frequency range to 10 kHz. Additional system hardware components include the PC-controlled Model 405/407 multi-channel signal conditioner with automatic gain adjustments for REF and DUT; MB Dynamics Model 500VI power amplifier; calibration accessory kit; Windows 10 PC, monitor, keyboard and printer; user manuals; and full onsite installation, start-up and training support.

The “4-in-1” MDAC marks the second in a series of recent automated accelerometer calibration systems by MB Dynamics, each launched in direct response to unique end-customer needs.

For more information, visit: www.mbdynamics.com