Courtesy: Onsemi

Every electronic device that is powered from a wall outlet uses some form of offline switch mode power supply (SMPS) that converts the AC grid voltage to a DC voltage used by the device. An offline SMPS is a switched power supply with an isolation transformer and covers power range from a few watts to multi-kilowatt solutions. Offline SMPS is widely deployed and indispensable in providing reliable and safe power to electronic devices in various applications ranging from consumer electronics, industrial power supply, datacenters to telecom base stations.

When designing an offline SMPS there are many factors to be considered for a successful design including power level, voltages, safety requirements, size, and several more.

Understanding Offline SMPS & Popular Topologies

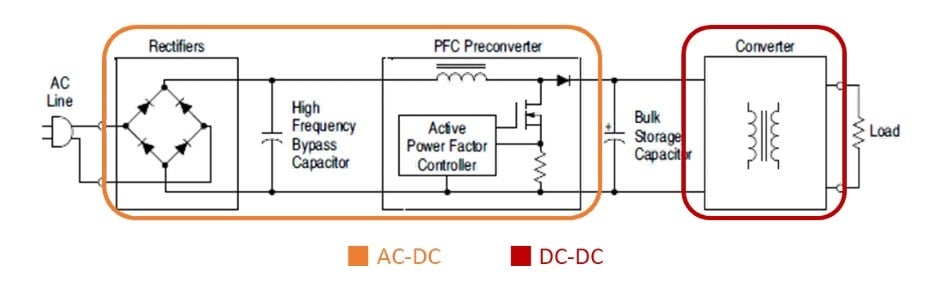

Fundamentally, an online SMPS uses a two-stage conversion. Firstly, the mains grid voltage is rectified and shaped by the first stage – the power factor corrector (PFC). The output voltage of the PFC stage is set to be a bit higher than the expected input peak voltage. For single phase solutions this is usually around 380-400 VDC. Since the output of the PFC stage is stable and relatively well-regulated DC voltage, the following DC-DC stage can be less complex. In most offline SMPS, the PFC is single-phase, but for higher power units (multi-kilowatt) it can be 3-phase.

The PFC stage aims to improve efficiency by reducing the apparent power in the system. It corrects the phase difference between the current and voltage (the ‘Power Factor’) to maintain as little difference as possible, as well as shaping the current waveform to be as near as it can be to a pure sinusoid, minimizing total harmonic distortion (THD).

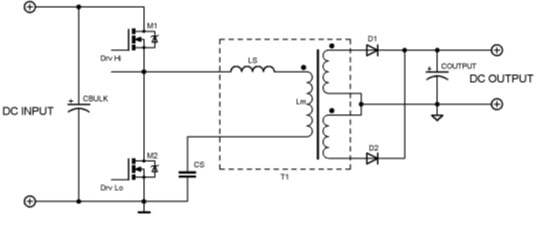

The DC-DC stage (often an LLC converter) takes the PFC output and converts this to the desired voltage, bearing in mind there may be several independent outputs. This stage also includes the galvanic isolation transformer that provides safety isolation as well as level shifting the voltage. Due to the transformer’s inability to accommodate direct current, the incoming DC from the PFC stage is converted back into an alternating current and then rectified for the output.

Efficiency (the ratio between the power delivered at the output and the power consumed by the input) is a crucial parameter for any SMPS. It affects the operating cost, but more importantly, it also defines the internal losses that manifest as heat. This, in turn, determines how much cooling is required when the SMPS is operating. The higher the amount of cooling in terms of fans and/or heatsinks is needed, the larger, heavier and more expensive the solution will be.

Advancements in Offline SMPS Technology

Striving for the highest levels of performance, there is ongoing advancement in the technologies used within offline SMPS.

Boost PFC is nowadays commonly used for a wide range of power due to its simple structure and straightforward control strategy. The inductor current is continuous, electromagnetic interference (EMI) is lower, and the current waveform is less distorted, which leads to a better power factor. A single-phase boost PFC will have a regulated DC output of around 380 V, which will then be converted by the DC/DC converter.

Furthermore, LLC converters are becoming increasingly popular for the DC-DC stage. These resonant converters regulate their output by altering the operating frequency of the resonant tank across a relatively narrow range, thereby operating in a soft-switching mode. This improves efficiency and reduces EMI. They operate at higher frequencies compared to allowing the use of smaller passive components.

Synchronous or active rectification is a technique for improving efficiency and reducing conduction losses by replacing rectifier diodes with active switches. While semiconductor diodes exhibit a relatively fixed voltage drop (typically 0.5 to 1 V), MOSFET switches act as resistances and therefore can have very low drop. If further improvements are needed, MOSFET switches can be paralleled in order to handle higher output currents. In such a case the conduction losses are reduced, because the RDSON of the paralleled devices is equal to the inverse sum of their respective RDSON.

Semiconductor materials are also evolving as traditional silicon (Si) has reached its limit for further significant performance gains. New wide-bandgap (WBG) materials such as silicon carbide (SiC) are increasingly preferred in power designs for their ability to operate efficiently at higher switching frequencies and higher operating voltages.

WBG devices exhibit lower losses due to better reverse recovery, significantly contributing to enhanced conversion efficiency. As a result, and due to their ability to operate at higher temperatures, thermal mitigation requirements are reduced when using WBG devices.

onsemi Solutions

onsemi has one of the broadest portfolios of solutions for offline SMPS currently available. At the heart of the range are controllers for the PFC and DC/DC converter stages, power MOSFETs, rectifiers, and diodes. This is supported with MOSFET gate drivers (including for synchronous rectification), optocouplers, low dropout (LDO) regulators, and other devices.

Leading the way in modern high-performance devices, the range includes many SiC devices (diodes and MOSFETs) for use in the most challenging offline SMPS applications.

Using the onsemi range (and a few passive components), offline SMPS from a few watts to several kilowatts can be designed. onsemi’s experience in this area assures designers that their solution will have industry-leading performance and reliability.

Conclusion

Offline SMPS are one of the most common sub-systems, present in almost every mains-connected device. However, to create a successful design, safety, and EMI regulations must be met while performance, especially in terms of efficiency, is an ever-increasing requirement.

While several companies manufacture some of the devices necessary for these designs, few (if any) have a comprehensive range that covers all the components (excluding passives) needed to execute a complete design. There are significant benefits to sourcing components from a single supplier, including knowing that devices have been designed and tested to work together.