Kansai University and Teijin Limited announced on December 22, 2016, that Professor Yoshiro Tajitsu, Faculty of Engineering Science, Kansai University, and Teijin have developed the world’s first piezoelectric roll made of multilayer piezoelectric film using alternately laminated polylactic acid (PLA).

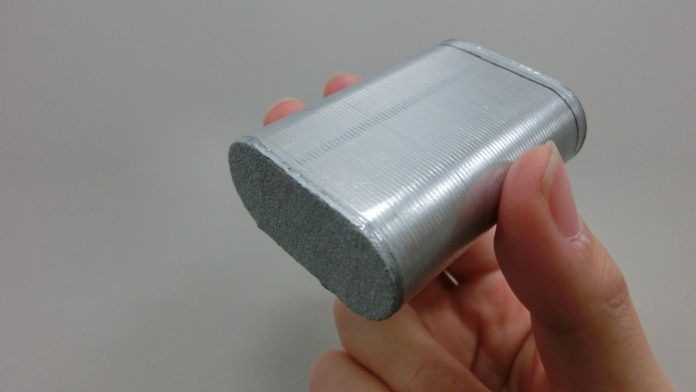

The new piezoelectric roll, which contains several µm PLA films wound hundreds to thousands of times, features a structure that enables load-dependent voltage generation and attenuation. It generates electric potential for up to two minutes with more than 90% of its maximum voltage when a sustainable load is applied. The new piezoelectric roll also is more flexible than conventional piezoelectric bodies, which could allow it to be used for sensors with adjustable piezoelectric duration and capabilities to physical enlargement and adjust winding numbers.

Kansai University and Teijin are now will continue working on the application development of environmentally conscious piezoelectric material to meet global demands.

Piezoelectricity is the ability of certain dielectric materials to generate an electric charge in response to mechanical stress. It also has the opposite effect – the application of electric voltage produces mechanical strain in the materials. Both of these effects can be measured, making piezoelectric materials effective for sensors.

Lead zirconate titanate (PZT) is a material with piezoelectric properties that has practical industrial applications, but as a ceramic it lacks transparency and flexibility. It also contains lead, so applications are being increasingly limited by directives that restrict the use of hazardous substances in electrical and electronic equipment. Polyvinylidene fluoride (PVDF), a well-known piezoelectric polymer, is sometimes used as a PZT substitute, but its pyroelectricity limits such opportunities.

To date, PLA is yet to be used widely because piezoelectric directionality makes it difficult to adjust the number of layers or to enlarge its size. Kansai University and Teijin jointly developed their flexible piezoelectric film by alternately laminating poly-L-lactide (PLLA) and the optical isomer poly-D-lactide (PDLA) in 2012. They also developed PLA fiber- and carbon-fiber-based piezoelectric fabrics in 2015.