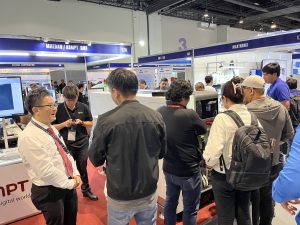

Singapore, July 31, 2024 – At the Philippines Semiconductor and Electronics Convention and Exhibition (PSECE) held from July 24 to 26 in Manila, ASMPT presented its Intelligent Factory concept to customers and interested parties with the help of hardware and software examples. The event created lots of interest and was rated very positively by attendees.

“I had already heard quite a lot about ASMPT’s Intelligent Factory concept,” said one happy attendee, “but this was the first time I could learn how it works in practice directly from ASMPT’s experts.”

“Holistic, data-driven, connected – our concept of the Intelligent Factory, which we first unveiled at the 2023 Productronica trade fair in Munich, is gradually becoming reality on many shop floors around the world,” says Peland Koh, Vice President Customer Relationship Management and Regional Managing Director Rest of Asia at ASMPT. “Being present at trade fairs like the PSECE strengthens our position in the Asian market and is highly appreciated by customers and other interested parties.”

Comprehensive use of data

“In the Intelligent Factory, hardware and software work hand-in-hand across lines and factories,” adds Peland Koh. “It allows users to increase their yields while providing relief for their employees’ workloads.”

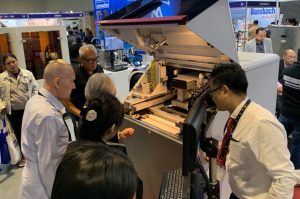

Visitors were able to experience trailblazing hardware and software solutions from ASMPT at the booth. Highlights included:

- DEK TQ: The innovative solder paste printer that sets new standards in cycle time, process stability, and precision.

- SIPLACE TX micron: The high-speed placement machine that processes classic SMDs with maximum accuracy and efficiency as well as highly sensitive dies in advanced packaging applications.

- Factory Equipment Center: The manufacturer-independent software that supports the intelligent tracking and maintenance of all production assets with a special focus on smart nozzles and feeders.

- Virtual Assist: The AI-based assistant on the smartphone that makes all repair and maintenance tasks easier for technicians by allowing them to ask questions in natural language.

- WORKS Monitoring: The intelligent application from the WORKS Software Suite that delivers all KPIs for an SMT shop floor at a glance in real time.

“The Intelligent Factory continues to be on everyone’s mind in the industry,” says Peland Koh. “With innovative and fully networkable hardware and software, we give our customers a clear competitive advantage. The overwhelming success of our presence at the PSECE shows that our strategy delivers exactly what electronics manufacturers need and want today.”