Scientists at Skoltech Center for Energy Science and Technology have developed an enriched and scalable approach for increasing the capacity of a broad range of metal-ion battery cathode materials.

The creation of modern lithium-ion batteries became possible owing to several scientific breakthroughs. Implementation of these materials helped to avoid unsafe anodes, such as lithium metal. However, problems including limited capacity, moderate cycling stability, low charge-discharge rate, issues with environmental friendliness, etc, still had to be solved.

Over the decades, researchers have been putting tremendous effort into developing better battery materials. As a result, various cathode materials with attractive properties have been proposed. However, the batteries that rely on these materials can often reach their full energy density only when they contain unsafe, highly reactive anodes with extractable cations. It is caused by the lack of mobile metal ions in the cathodes. This issue leads to limited capacity and, in many cases, complicates the practical implementation of otherwise appealing materials.

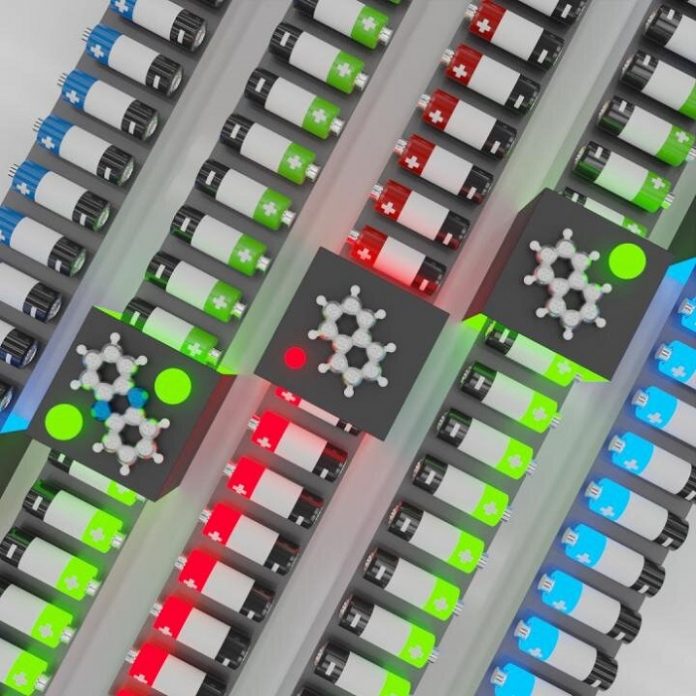

It was proposed to treat the cathodes with solutions of reducing agents, which are alkali metal salts derived from aromatic compounds, for example, naphthalene or phenazine.

An important advantage of the approach is its scalability. The process requires no sophisticated conditions and is relatively safe. Additionally, the reducing agents can be recycled after they react with the cathodes because their redox chemistry is reversible. These features make the method promising for large-scale applications.

This approach is suitable for a broad spectrum of organic and inorganic battery materials. Moreover, it turned out to be applicable not only for lithium-ion batteries but also for sodium- and potassium ion batteries, which are potentially more sustainable and lower-cost energy storage devices. It was possible to control the content of metal ions in the cathodes by adjusting the amount of the reducing agents or their oxidation potentials.

“The approach can serve as a powerful toolkit, which may be used to improve the performance of various battery materials,” says Roman Kapaev. “It is also a straightforward and inexpensive method with recyclable reagents, so we believe that it is suitable for large-scale practical applications.”