Introduction

In tantalum capacitor manufacturing, there is a steam pyrolysis process where tantalum pellets are decomposed by steam. Humidity control in this process is important to maintain product quality and improve yield.

Stable humidity measurement at high temperatures of 200 to 400 °C is required. The ZR802G Zirconia High Temperature Humidity Analyzer is easy to maintain because of direct insertion in process without sampling system and utilizes a long-life sensor with fast response. It is widely used in humidity instrumentation applications and has been well received in the marketplace.

Expected Benefits

- Maintains the quality of the tantalum capacitor manufacturing process

- Ensures stable, continuous humidity measurement

- Reduces operating costs

Process Overview

A tantalum pellet with an electrode plate applied is immersed in a manganese nitrate solution. This dipping process allows the manganese nitrate to penetrate the porous part of the pellet. After dipping, the pellet is forwarded to the pyrolysis process where the manganese nitrate is decomposed under high temperature and humidity conditions to form a manganese dioxide coating by the reaction Mn(NO3)2 -> MnO2 + 2NO2. These steps are repeated until the coating is sufficient. To improve the coating uniformity and yield, the humidity is controlled.

Process conditions

Measurement point: Inside the steam

pyrolysis furnace Temperature: 200 to 400 ℃

Pressure: 10 to 20 Pa

Humidity: 25 to 80 vol%H2O Dust: None

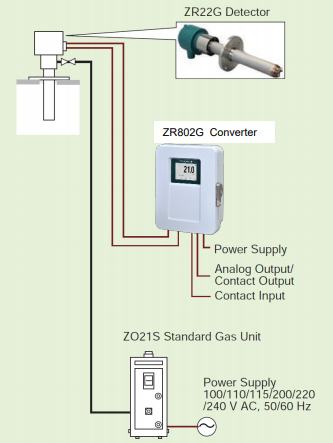

Measurement system

Detector: ZR22G-☐☐☐-S-☐-C-R-☐-E-A /SV Converter: ZR802G-☐-☐-N-N /□

Standard gas unit: ZO21S-☐ -E*A

Utilities

Rated voltage: 100 to 240 V AC Rated frequency: 50/60 Hz

Power consumption: 330 VA (Max. 800 VA)

Notes on Installation

As the sensor inside a pyrolysis furnace is hot, it can be easily damaged if cooler water drips onto it. The sensor should be installed with the probe head pointing downward.