Jeff Shepard, Editors, Digi-Key

Chargers for electric vehicles (EVs) come in various voltage and power levels, but all rely upon capacitors to perform functions like DC input filtering, DC linking, AC harmonic filtering, DC output filtering, and in some designs, supercapacitors are used in combination with battery energy storage and solar inverters. As EV chargers are often located outdoors or in other rugged environments, designers are challenged to first determine the capacitor performance profile and then select the appropriate capacitor type to meet demanding reliability characteristics.

Designers need to ensure the capacitor is physically rugged with wide operating temperature ratings and long operational lifetimes. The capacitors need to be compact and able to handle large ripple currents without overheating or suffering performance degradation, and they need to meet the electrical and mechanical requirements of AEC-Q200, as well as the performance requirements of International Electrotechnical Commission (IEC) 61071, and some need to meet ANSI/IEEE Standard 18.

To meet the diverse needs of those circuit applications, designers can turn to a variety of capacitor technologies like power film capacitors, aluminum electrolytic capacitors, and supercapacitors, including low-inductance designs, capacitors with high ripple current ratings, high operating temperatures, self-healing capabilities, AEC-Q200 qualifications that meet IEC 61071, and supercapacitors with low equivalent series resistance (ESR).

This article defines the various charging levels and reviews circuit applications for capacitors in solar power inverters based on these levels. It then presents examples of input filtering, power film DC link, AC harmonic filtering, and output filtering capacitors and supercapacitors from Cornell Dubilier Electronics suited for a variety of EV charger designs, along with package options for integrating these capacitors into printed circuit boards (pc boards), attaching them to busbars, or directly connecting them to insulated gate bipolar transistor (IGBT) modules to ensure a successful design.

EV charging levels and requirements

There are three EV charging levels: Level 1 residential charging provides 120 volts of alternating current (VAC) power; Level 2 residential and public charging provides 208/240 VAC power; and Level 3 commercial and public chargers provide 400 to 900 volts direct current (VDC) power for DC fast charging and supercharging. Some Level 1 and Level 2 chargers are based on solar inverters and battery energy storage.

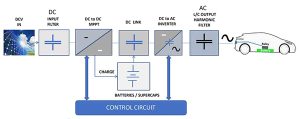

Increasingly common solar-powered Level 1 and Level 2 chargers include a direct current to direct current (DC-DC) converter and a DC to alternating current (DC-AC) inverter. They need a variety of high-performance capacitors that have been designed for use in harsh electrical conditions that meet AEC-Q200 and IEC 61071 standards, including the types shown in Figure 1:

- DC input filter and DC link capacitors: These chargers need low-inductance DC input filter and DC link capacitors that have been optimized for medium-power applications. They can benefit from using capacitors with values up to 1 Farad (F) or more, and low equivalent series resistance (ESR) to minimize internal heating.

- AC output filter capacitors: IGBT-based switched-mode power inverters can produce high harmonic content and total harmonic distortion (THD) that must be filtered using AC output filter capacitors. If not adequately filtered, the harmonics can distort the output AC waveform.

- Supercapacitors: The addition of supercapacitors can be especially beneficial in Level 1 and Level 2 solar-powered chargers to help the system adjust for changes in insolation as clouds obstruct the relatively small solar panels, resulting in peaks and valleys in output power. In these systems, the ratio between peak power and average power can challenge battery-only systems. The combination of supercapacitors and batteries can result in a system with a higher power density.

Figure 1: A variety of capacitors and supercapacitors are needed for solar-powered inverter EV chargers. (Image source: Cornell Dubilier Electronics)

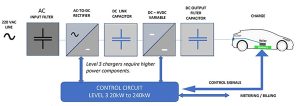

Capacitors are also important in the design of Level 3 DC fast chargers that use AC-DC power conversion. Like Level 1 and Level 2 chargers, DC fast chargers need DC link capacitors. The DC link capacitors in DC fast chargers are higher power devices and usually have higher voltage ratings. In addition, Level 3 chargers need AC input filter capacitors and DC output filter capacitors (Figure 2):

- AC input filter capacitors: To support higher power levels, these capacitors are often packaged differently compared with devices designed for lower power handling. For example, while lower power filtering capacitors in Level 1 and 2 chargers can have snap-in terminations for quick attachment to pc boards or solderable pins, capacitors used in Level 3 DC fast chargers often have screw terminals that attach directly to high-power busbars. The input capacitors for Level 3 chargers can be required to meet ANSI/IEEE Standard 18.

- DC output filter capacitors: These capacitors serve a similar function to the AC harmonic filter capacitors in Level 1 and Level 2 solar-powered chargers. They absorb transients and filter the harmonic currents generated by the DC-DC IGBT switching stage of the charger, smoothing the output voltage. These capacitors need to combine low ESR with high ripple current capability.

Figure 2: Grid-powered Level 3 DC chargers require components that can handle high currents and voltages. (Image source: Cornell Dubilier Electronics)

Capacitors for Level 1 & Level 2 PV EV chargers

DC input filtering: Cornell Dubilier offers designers several aluminum electrolytic capacitor options for DC input filtering on Level 1 and Level 2 EV chargers, including the DCMC screw terminal capacitors, and the 380LX/382LX +85°C and the 381LX/383LX +105°C snap-in capacitors (Figure 3). DCMC capacitors range from 110 µF to 2.7 F, voltages up to 550 volts, an operating temperature range of -40°C to +85°C, and can handle high levels of ripple current. Type 380LX capacitors have a load life of 3,000 hours (hr) at full load at +85°C, while 381XL capacitors have a load life of 3,000 hr at full load at +105°C. The 380LX/382LX and 381LX/383LX capacitors are available with 2, 4, and 5-pin styles to support secure and accurate mounting to pc boards.

Figure 3: The 381LX and related capacitors have snap-in pc board connections. (Image source: Cornell Dubilier Electronics)

DC linking: For DC linking, designers can select from type 550C aluminum electrolytics like the 550C562T400DP2B and 947D series metalized film capacitors like the 947D601K901DCRSN. The 550C series has an operating life of over 100,000 hours in typical applications and up to 20,000 hours at +85°C operation. 550C capacitors have ESRs down to 7 milliohms (mΩ) and feature screw terminals for attaching to a pc board or busbar, and can handle high ripple currents.

The 947D series combines high capacitance and very high ripple current capability needed for inverter designs. These capacitors are available with voltage ratings from 900 to 1,300 VDC. They are rated for 7,000 hours of operation at +85°C and have a life expectancy of 350,000 hours at +60°C core temperature and full rated voltage.

AC output harmonic filtering: To provide AC output harmonic filtering in harsh environments, designers can turn to AEC-Q200 qualified type ALH series AC filter capacitors. Compared to standard capacitors, these capacitors have a 50% greater life based on accelerated 85/85 temperature-humidity-bias (THB) testing. They have high root-mean-square (RMS) current ratings that make them suited to handling higher order harmonics in high-frequency IGBT based inverters. Capacitance ranges are from 0.22 to 50 microfarads (µF) at 160 to 450 VAC, 50/60 Hertz (Hz). These self-healing, metalized polypropylene-film capacitors come in a robust board-mount package (Figure 4) and have an operating temperature range of -40°C to +105°C. ALH series capacitors have a life expectancy of 100,000 hours at rated voltage and a hot spot temperature of +70°C.

Figure 4: The ALH series AC filter capacitors provide AC harmonic output filtering in harsh environments, are self-healing, and are designed for through-hole mounting on pc boards. (Image source: Cornell Dubilier Electronics)

Supercapacitors: For designs that need the instantaneous bursts of power that supercapacitors can provide, Cornell Dubilier offers the DGH series and the DSF series. The DGH series includes 21 different value/voltage combinations, ranging in capacitance from 0.5 to 600 F, with voltage ratings from 2.7 to 5.5 working volts DC (WVDC). DSF supercapacitors offer a higher 3.0 WVDC for a single component and a 6.0 WVDC for a dual device (Figure 5). This higher voltage specification results in a 24% higher energy density. The DSF series includes 17 different value/voltage combinations, ranging in capacitance from 1.5 F to 600 F. Both series are rated for 500,000 cycles. They are available with a choice of through-hole leads or snap-in leads for integration into pc boards.

Figure 5: The DSF supercapacitors are available as dual and single devices. (Image source: Cornell Dubilier Electronics)

Capacitors for Level 3 chargers

AC input and harmonic filtering: For the high power levels supported by Level 3 DC chargers, designers can turn to the PFCH series of three-phase series capacitors, like the PFCHX48D20S108T, which is rated for 76.8 µF and 480 VAC and is designed for AC input harmonic filtering. These capacitors consist of three self-healing metalized polypropylene windings that are connected in a delta configuration and enclosed in a cylindrical aluminum case. They have a lifetime rating of 60,000 hr with a 94% survival rate and a failure-in-time (FIT) rating of ≤300 X 109 component hours. They include a pressure interrupter that disengages all three phases in the event of capacitor end-of-life or overload. They meet ANSI/IEEE Standard 18 and have a maximum short circuit current rating of 10 kiloamperes (kA) according to UL 810.

DC linking: DC linking capacitor choices include the BLH DC Link capacitors designed for pc board mounting that are tested for 1,500 hours at +85°C / 85% relative humidity with rated voltage applied, and the 474 series, like the 0.47 µF, 1.2 kilovolts DC (kVDC) 474PMB122KSP2 film capacitor that is designed for direct mounting on IGBT modules to provide DC linking and filtering.

BLH capacitors are rated for operation from -40°C to +105°C with the rated voltage derated above +85°C by 1.35% per °C, and they meet the requirements of IEC 61071 and AEC- Q200. 474 series capacitors like the 474PMB122KSP2 are rated for operation from -40°C to +100°C, with the DC voltage decreased by 1.5% and the AC voltage decreased by 2.5% per °C above +85°C.

DC output filtering: The 944U series of high-current film capacitors includes devices rated for 800, 1000, 1200, and 1400 VDC, with capacitance ratings from 33 µF to 220 µF and RMS current ratings up to 75 A at +55°C. The high ripple capability is a result of the low-inductance internal construction of these metalized polypropylene capacitors. They are packaged in a low-profile UL94V0 flame-retardant case that’s 84.5 millimeters (mm) in diameter, with mounting flanges at the base and M8 threaded stud terminals (Figure 6). Depending on the ratings, case heights are 40 mm, 51 mm, or 64 mm.

Figure 6: The screw connections of 944U film capacitors can be used for pc board or bus bar connections. (Image source: Cornell Dubilier Electronics)

Conclusion

As shown, EV chargers require a wide range of capacitor types to ensure reliable and efficient operation. Cornell Dubilier offers a wide selection of capacitor types and mounting styles to support the design and construction of high-performance chargers for Level 1, 2 and 3 applications.