Electric vehicles (EVs) are playing an increasingly important role in reducing greenhouse gas (GHG) emissions to address climate change concerns. However, the successful design and deployment of EVs, and EV supply equipment (EVSE) like battery chargers, requires designers to address a wide range of technological challenges. These include overvoltage and overcurrent circuit protection, the suppression of electromagnetic interference (EMI), the design of power supplies with wide input and operating temperature ranges, and the ongoing need to reduce weight to improve EV range.

For example, a battery management system (BMS) and control interface in an EVSE system needs auxiliary AC/DC power supplies that can operate over an input voltage range of 85 to 305 volts AC (VAC), and a temperature range of -40°C to +85°C. To address weight, designers need to consider moving from the venerable and well-established CAN bus to automotive grade Ethernet that can support higher bandwidths with lighter cables.

This article provides a brief overview of the basic levels of EV chargers. It then discusses the different needs of each type related to auxiliary AC/DC power supplies (aux power), provides overvoltage and overcurrent protection options, and looks at how to implement Ethernet connectivity and suppress EMI to avoid distorting high-speed signals. Examples of real-world solutions to address the various design issues will be introduced from providers like Bel Fuse, Signal Transformer, Stewart Connector, and CUI.

Introduction to EV and EVSE charging requirements

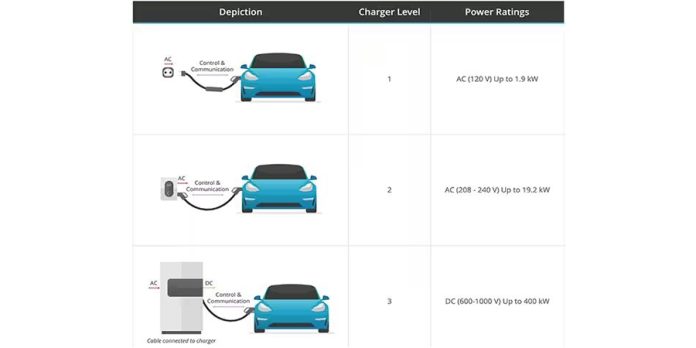

The deployment of large numbers of EVSEs, including battery chargers and charging piles, will be key to widespread EV adoption. Note that EV battery chargers are internal to the EV while charging piles refers to external charging stations. SAE J1772, the North American standard for EV connectors, defines four EV charging levels:

- AC Level 1 uses 120 VAC to deliver up to 16 amperes (A) or 1.9 kilowatts (kW) AC Level 2 uses 208 to 240 VAC to deliver up to 80 A or 19.2 kW

- DC Level 1 uses up to 1,000 VDC to deliver up to 80 A or 80 kW

- DC Level 2 uses up to 1,000 VDC to deliver up to 400 A or 400 kW

While SAE defines the two DC levels separately, they are often lumped together and referred to as Level 3, or DC fast charging. In addition to the different input voltages and power levels, AC charging piles require a separate onboard charger (OBC) in the vehicle to handle the AC/DC conversion and BMS functions needed to safely and efficiently charge the battery pack. In the case of DC fast charging, there is no need for an OBC; the power conversion and BMS functions are in the charging pile. Each level of charging includes communication (signaling) between the vehicle and the charging pile (Figure 1).

Aux power needs

Per SAE J1772 requirements, aux power is needed to support the general operation of the charging pile and the signaling functions when connecting the charging pile controller with the vehicle controller. The signal protocol is designed to ensure efficient and safe charging, utilizing continuous two-way connectivity between the pile and the vehicle.

The basic power requirement calls for an AC/DC power supply that delivers 12 VDC for signaling and has an operating temperature range of −40 to +85°C. Complete solutions need electromagnetic compatibility (EMC) and protection circuitry, and they usually have a separate DC/DC converter to supply a lower voltage to other components, such as 3.3 volts to power a microcontroller unit (MCU).

The exact power needs depend on the design of the charging pile. For example, a Level 1 charger is a simple design with minimal power needs, and aux power that can be supplied with a miniature 5-watt AC/DC power supply mounted on a printed circuit board (pc board). Level 2 charging piles are more complex and need about 50 watts of aux power. Both operate off single-phase AC inputs, but with different input voltage requirements; 120 VAC for Level 1, and 208 to 240 VAC for Level 2.

Things change significantly with Level 3 charging piles. The charging circuitry in the pile operates on three-phase power, often 480 VAC. The aux power supply is fed with single-phase power and needs a wide input voltage range, such as 85 to 305 VAC. The output power is also higher, often 150 watts or more, enabling a wider range of features including additional controls like payment functions, a display, and a BMS. It can have a single output, such as 24 VDC for overall system power. The system will have a series of distributed DC/DC converters to supply the 12 VDC needed for signaling, a separate 12 VDC rail for the BMS, and 3.3 VDC for the MCU and other components. In addition to EMC and standard protection functions, these power solutions require power factor correction (PFC), and protection from high inrush currents when they are turned on.

Aux power supplies

The good news for designers is that they don’t have to build aux power supplies from scratch. Instead, there are off-the-shelf solutions for all types of EV charging piles available now from the CUI division of Bel Fuse. For example, the PBO series of 3, 5, 8, and 10-watt board-mounted AC/DC power supplies are suitable for Level 1 chargers. The model PBO-5C-12 delivers 5 watts with a 12 VDC output from an input voltage range of 85 to 305 VAC, and it’s rated for operation over a temperature range of -40°C to +85°C.

Level 2 charging piles require more aux power and can use the PSK series of AC/DC power supplies, like the enclosed 10-watt PSK-10D-12 that delivers 830 milliamperes (mA) at 12 VDC. This supply has the same input voltage range and operating temperature specifications as the PBO-5C-12. Both the PBO and PSK series feature overcurrent and short-circuit protection, but the PSK series adds overvoltage protection.

For Level 3 charging piles, CUI’s VGS series of AC/DC power supplies can deliver up to 350 watts. These supplies have short-circuit, overcurrent, overvoltage, and over-temperature protection, as well as inrush current limiting and active PFC. They meet CISPR/EN55032 Class B for radiated/conducted emissions and IEC 61000-3-2 Class A for harmonics limitations. An example model is the VGS-100W-24. It delivers 108 watts of power with an output voltage of 24 VDC and a typical efficiency of 89.5% (Figure 2).

Overcurrent protection

To provide overcurrent protection for high-voltage rails, Bel Fuse offers fast-acting and rugged ceramic fuses with ratings of 240, 500, and 1,000 volts. They are designed for use in main EV battery packs, junction boxes, charging piles and related applications, and meet the requirements of the JASO D622/ISO 8820-8 fuse standard for road vehicles. The model 0ALEB9100-PD cartridge bolt-mount ceramic fuse is rated for 10 A and 500 volts (Figure 3).

Overtemperature protection

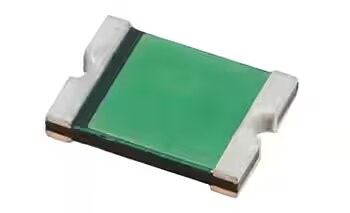

Overtemperature protection is also important in EV charging piles and battery packs. For these applications, Bel Fuse offers the 0ZT series high-temperature resettable fuses. These positive temperature coefficient (PTC) devices have a high operating temperature range of -40°C to +125°C, and provide the required trip and hold currents for robust over-temperature protection. The 0ZTH0020FF2E, for example, is rated for 30 volts with a trip current of 500 mA and a hold current of 200 mA (Figure 4). Like other PTC devices in the OZT series, it is well-suited for operation in high ambient temperature environments.

Connectivity and signal integrity

In addition to aux power and protection functions, EV charging piles require high-speed connectivity and a high degree of signal integrity for reliable operation. These requirements are easily met by automotive Ethernet, based on IEEE 802.3ch with data rates of up to 10 gigabits per second (Gbits/s). Automotive Ethernet is rapidly replacing the traditional CAN bus with its data rate of 1 megabit per second (Mbit/s). This is in part because of automotive Ethernet’s high data rate, but also because it delivers this data over an unshielded, single twisted-pair cable that is designed for both low weight and minimal cost.

The use of Ethernet is expected to continue growing with the scheduled release of IEEE 802.3dh in 2024. This standard will deliver multi-gigabit automotive Ethernet over plastic optical fiber (POF). Some advantages of POF in automotive applications include high elastic strain limits, high fracture toughness, and high flexibility, making it a good choice for replacing twisted pair Ethernet cabling.

Meanwhile, for today’s automotive designs, the Stewart Connector division of Bel Fuse offers automotive grade RJ45 Ethernet modular connectors that comply with the SAE/USCAR2-6 standard for vibration and sealing requirements. They are available in right-angle and vertical mount designs, with multiple LED configurations and an operating temperature range of -40°C to +100°C.

The connectors can accommodate power-over-Ethernet (PoE) at levels up to 100 watts. Since crosstalk and return loss are often challenges with this style of PoE connector, their contact design has been optimized for high performance in high-frequency applications. They are also optimized for a small footprint.

Non-LED versions of the Stewart RJ45, such as the SS-60300-011, are IR reflow compatible, and all devices in the line have contacts selectively plated with 50 micro-inches of gold for improved performance. The SS-60300-011 is designed for horizontal orientation (Figure 5).

To ensure signal integrity, the Signal Transformer division of Bel Fuse offers the SPDL series of surface mount, common-mode chokes for EMI suppression of differential-mode noise. It filters signals over Ethernet and other high-speed interfaces with virtually no signal distortion. These common-mode chokes are rated for currents up to 6.5 A with impedances from 90 to 2200 ohms (Ω), and have an operating temperature range of -40°C to +125°C. For example, model SPDL3225-101-2P-T is rated at 5100 Ω (typical), 50 volts, and 150 mA (Figure 6).

Conclusion

The deployment of EVSE systems like EV charging piles is important to support large-scale EV use and the accompanying reduction in GHGs. A range of EV charging pile types are needed that can support both slow AC charging and DC fast charging. To ensure the successful design and safe deployment of EVs and EVSEs, designers can take advantage of readily available, specialized systems and devices for power conversion and delivery, circuit protection, and EMI mitigation.