It doesn’t seem difficult to build a basic step-down (buck) DC/DC regulator for low voltages of 10 volts (typical) or less and modest current levels of about 2 to 15 amperes (A). The designer just needs to select a suitable switching regulator IC and add a few passive components using the example circuit on the datasheet or application note. But is the design really done and ready to release to pilot run, or even to production? Probably not.

While the regulator provides the desired DC rail, it still has several potential problems and issues. First, the efficiency may not meet project objectives or regulatory requirements, thereby adding to thermal impact, as well as shorter battery life. Second, additional components may be needed to ensure proper start-up, transient performance, and low ripple, which in turn affects size, time to market, and the overall bill of material (BOM). Finally, and perhaps most challenging, the design may not meet the increasingly stringent limitations on electromagnetic interference (EMI) or radio frequency interference (RFI) as defined by the various regulatory mandates, thus requiring a redesign or further additional components and testing.

This article describes the gap between expectations and performance between a basic DC/DC regulator design and a superior one that meets or exceeds requirements for efficiency, low radiated and ripple noise, and overall integration. The article then introduces Analog Devices’ Silent Switcher µModules and shows how to use them to solve multiple DC/DC buck regulator problems.

ICs make it look easy, at first

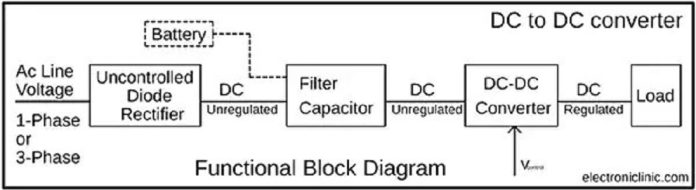

Step-down DC/DC (buck) regulators are widely used to provide DC rails. A typical system may have tens of these providing different rail voltages or physically separated rails at the same voltage. These buck regulators commonly take a higher voltage, typically between 5 and 36 volts DC, and regulate it down to a single-volt value at a few or low double-digit amperes (Figure 1).

There’s good news and bad news when constructing a basic buck regulator. The good news is that building one that provides nominally “good-enough” performance is generally not difficult. There are many switching ICs available to do the bulk of the task that need only a single field effect transistor (FET) (or none at all) and a few passive components to complete the job. The task is made even easier as the datasheet for the regulator IC almost always shows a typical application circuit with a schematic, a board layout, and a BOM that may provide component vendor names and part numbers.

The engineering dilemma is that a “good” level of performance may not be adequate with respect to some non-obvious regulator performance parameters. While the output DC rail may deliver enough current with adequate line/load regulation and transient response, those factors are only the beginning of the story for power rails.

The reality is that in addition to those basic performance criteria, a regulator is also assessed by other factors, some of which are driven by external imperatives. The three critical issues which most regulators must address are not necessarily apparent, solely from the simplistic perspective of a functional block that accepts an unregulated DC input and provides a regulated DC output. They are (Figure 2):

- Cool: High efficiency and associated minimal thermal impact.

- Quiet: Low ripple for error-free system performance, plus low EMI to meet radiated noise standards (non-acoustic).

- Complete: An integrated solution that minimizes size, risk, BOM, time to market, and other “soft” concerns.

Addressing these issues brings a set of challenges, and solving them can become a frustrating experience. This is in line with the “80/20 rule”, where 80% of the effort is devoted to getting the last 20% of the task done. Looking at the three factors in more detail:

Cool: Every designer wants high efficiency, but exactly how high, and at what cost? The answer is the usual one: it depends on the project and its tradeoffs. Higher efficiency is important for three main reasons:

- It translates into a cooler product that enhances reliability, may allow for operation at a higher temperature, may eliminate the need for forced air (fan) cooling, or may simplify setting up effective convection cooling if feasible. At the high end, it may be needed to keep specific components that run particularly hot below their maximum allowed temperature and within their safe operating area.

- Even if these thermal factors are not a concern, efficiency translates to longer run time for battery-operated systems or a reduced burden on the upstream AC-DC converter.

- There are now many regulatory standards mandating specific efficiency levels for each class of end product. While these standards do not call out efficiency for individual rails in a product, the designer’s challenge is to ensure that the overall aggregate efficiency meets the mandate. This is easier when each contributing rail’s DC/DC regulator is more efficient, as that provides for headroom in the summation with the other rails and other sources of loss.

Quiet: There are two broad classes of noise that concern designers. First, the noise and ripple on the output of the DC/DC regulator must be low enough so that it does not adversely affect system performance. This is an increasing concern as rail voltages drop to low single digits in digital circuits, as well as for precision analog circuits where ripple of even a few millivolts can degrade performance.

The other major concern is related to EMI. There are two types of EMI emissions: conducted and radiated. Conducted emissions ride on the wires and traces that connect to a product. Since the noise is localized to a specific terminal or connector in the design, compliance with conducted emissions requirements can often be assured relatively early in the development process with a good layout and filter design.

Radiated emissions, however, are more complicated. Every conductor on a circuit board that carries current radiates an electromagnetic field: every board trace is an antenna, and every copper plane is a mirror. Anything other than a pure sine wave or DC voltage generates a wide signal spectrum.

The difficulty is that even with careful design, a designer never really knows how bad the radiated emissions are going to be until the system gets tested, and radiated emissions testing cannot be formally performed until the design is essentially complete. Filters are used to reduce EMI by attenuating the levels at specific frequencies or over a range of frequencies using various techniques.

Some of the energy radiating through space is attenuated by using sheet metal as a magnetic shield. The lower frequency part that rides on pc board traces (conducted) is controlled using ferrite beads and other filters. Shielding works but brings a new set of problems. It must be well-designed with good electromagnetic integrity (often surprisingly difficult). It adds cost, increases real estate, makes thermal management and testing more difficult, and introduces additional assembly costs.

Another technique is to slow down the switching edges of the regulator. However, this has the undesired effect of reducing the efficiency, increasing minimum on and off times as well as the required dead times, and compromising the current-control-loop speed.

Still another approach is to adjust the regulator design to radiate less EMI by careful selection of the key design parameters. The task of balancing these regulator tradeoffs involves assessing the interaction of parameters such as switching frequency, footprint, efficiency, and resultant EMI.

For example, a lower switching frequency generally reduces switch loss and EMI and improves efficiency, but requires larger components with associated increases in footprint. The quest for greater efficiency is accompanied by low minimum on and off times, resulting in higher harmonic content due to the faster switch transitions. In general, with every doubling of switching frequency, the EMI becomes 6 decibels (dB) worse, assuming all other parameters such as switch capacity and transition times, remain constant. The wideband EMI behaves like a first-order high-pass filter with 20 dB higher emissions when the switching frequency increases by a factor of ten.

To overcome this, experienced pc board designers will make the regulator’s current loops (“hot loops”) small, and use shielding ground layers as close to the active layer as possible. Nevertheless, pinout, package construction, thermal design requirements, and package sizes needed for adequate energy storage in decoupling components dictate a certain minimum hot-loop size.

To make the layout problem even more challenging, the typical planar pc board has magnetic or transformer-style coupling between traces above 30 megahertz (MHz). This coupling will attenuate the filtering efforts since the higher the harmonic frequencies, the more effective unwanted magnetic coupling becomes.

Which standards are relevant?

There is no single guiding standard in the EMI world, as it is largely determined by the application and relevant governing mandates. Among the most cited ones are EN55022, CISPR 22, and CISPR 25. EN 55022 is a modified derivative of CISPR 22 and applies to information technology equipment. The standard is produced by CENELEC, the European Committee for Electrotechnical Standardization, and is responsible for standardization in the electrotechnical engineering field.

These standards are complex and define the test procedures, probes, instrumentation, data analysis, and more. Among the many limits defined by the standard, the Class B radiated emission limit is often of most interest to designers.

Complete: Even when the design situation is fairly well understood, selecting and employing the needed support components in just the right way is a challenge. Slight differences in component placement and specifications, pc board grounds and traces, and other factors can adversely affect performance.

Modeling and simulation are necessary and can help, but it’s very difficult to characterize the parasitics associated with these components, especially if their values shift. Further, a change in vendors (or unannounced change by the preferred vendor) may induce a subtle shift in second- or third-tier parameter values (such as inductor dc resistance (DCR)), which could have significant and unanticipated consequences.

Further, even slight repositioning of the passive components or adding “just one more”, can change the EMI scenario and result in emissions exceeding allowable limits.

SilentSwitcher µModules resolve the issues

Anticipating and managing risk is a normal part of a designer’s job. Reducing the number and intensity of these risks is a standard end-product strategy. A solution is to use a functionally complete DC/DC regulator that, through good design and implementation, is cool, quiet, and complete. Using a known device reduces uncertainty while addressing size, cost, EMI, BOM, and assembly risks. Doing so also accelerates time to market and reduces regulatory compliance angst.

By looking at a complete family of such regulators, such as the Silent Switcher µModules from Analog Devices, designers can choose a DC/DC regulator matched to the needed voltage and current rating, while being assured that EMI mandates will be met, size and cost will be known, and there will be no surprises.

These regulators incorporate much more than innovative schematics and topologies. Among the techniques they use are:

- Technique #1: The switching of the regulator acts as an RF oscillator/source and combines with the bond wires, which act as antennas. This turns the assembly into an RF transmitter with undesired energy that may exceed allowed limits (Figures 3, 4, and 5).

- Technique #2: The use of symmetrical input capacitors bounds EMI by creating balanced, opposing currents (Figure 6).

- Technique #3. Finally, the use of opposite current loops to cancel magnetic fields (Figure 7).

These Silent Switcher µModules represent the evolution of step-down regulator design and packaging from an IC with support components to an LQFN IC with integral capacitors to a µModule with requisite capacitors and inductors (Figure 8).

Broad offering addresses needs, tradeoffs

The Silent Switcher µModules comprise many individual units with different ratings for input voltage range, output voltage rail, and output current. For example, the LTM8003 is a 3.4 to 40-volt input, 3.3-volt output, 3.5 A continuous (6 A peak) µModule that meets CISPR 25 Class 5 limits, yet measures just 9 × 6.25 millimeters (mm) and 3.32 mm high (Figure 9).

It is offered in a pinout which is failure mode effects analysis (FMEA) compliant (LTM8003-3.3), meaning that the output stays at or below the regulation voltage during an adjacent-pin short circuit or if a pin is left floating. The typical quiescent current is just 25 microamperes (µA), and the H-grade version is rated for 150°C operation.

The DC2416A demonstration (demo) board is available for designers to exercise the regulator and assess its performance for their application (Figure 10).

Two nominally similar Silent Switcher µModule family members, the LTM4657 (3.1 to 20-volt input; 0.5 to 5.5 volt @8 A output) and the LTM4626 (3.1 to 20-volt input; 0.6 to 5.5 volt at 12 A output), show the nature of the tradeoffs that the devices offer. The LTM4657 uses a higher value inductor than the LTM4626, allowing it to operate at lower frequencies to decrease switching loss.

The LTM4657 is a better solution for high switching losses and low conduction losses, such as in applications where the load current is low and/or the input voltage is high. Looking at the LTM4626 and LTM4657 operating at the same switching frequency, and with the same 12-volt input and 5-volt output, the superior switching loss of the LTM4657 can be seen (Figure 11). Additionally, its higher-value inductor reduces the output voltage ripple. However, the LTM4626 can supply more load current than the LTM4657.

Users can assess the performance of the LTM4657 using the DC2989A demo board (Figure 12), while for those who need to evaluate the LTM4626, the DC2665A-A board is available (Figure 13).

The Silent Switcher µModules are not restricted to single-output modules. For example, the LTM4628 is a complete, dual 8 A output switching DC/DC regulator that can be easily configured to provide a single 2-phase 16 A output (Figure 14). The module is offered in 15 mm × 15 mm × 4.32 mm LGA and 15 mm × 15 mm × 4.92 mm BGA packages. It includes the switching controller, power FETs, inductor, and all supporting components.

The module operates over an input voltage range of 4.5 to 26.5 volts and supports an output voltage range of 0.6 to 5.5 volts, set by a single external resistor. Users can investigate its performance as a single or dual-output device using the DC1663A demo board (Figure 15).

Conclusion

Designing a functioning DC/DC regulator is fairly easy with available ICs. However, designing a regulator that simultaneously excels in efficiency, is functionally complete, and meets the often various confusing and stringent regulator mandates is not. The Silent Switcher µModules from Analog Devices simplify the design process. They eliminate risk by meeting the goals for cool and efficient operation, EMI emissions below allowed limits, and drop-in completeness.

Authored Article by: