This article explores different aspects of conformal coatings, circumnavigating a plethora of coating topics as comprehensively as possible to ensure you get the most from your coating process. Thoughtful design will always pay huge dividends down the line and the designers among you will have friends for life among your production colleagues if you make their jobs just that little bit easier! Identifying potential production problems at the design stage will always be preferable and far easier than trying to fix problems following finalization of the engineering drawings. So, let us take a closer look at how we can achieve maximum performance for your conformal coatings process.

Choosing a coating: the prime considerations

Firstly, determine the expected operational temperature range for the circuit board – the highs and the lows. If it is greater than 150-160°C, for example, it is almost certainly an application for a silicone rather than an acrylic or polyurethane conformal coating. Also, consider the temperature excursions; if thermal shock or thermal cycling is not taken into consideration it could lead to cracking, severely compromising a coating’s protective capabilities.

Secondly, what degree of chemical resistance is required? Acrylic materials, whilst ideal for rework, are generally highly susceptible to attack by solvents; polyurethane materials, however, provide more chemical resistance but are not as amenable to rework. Assess whether immersion or splash resistance is required and whether the coating may be exposed to heated solutions of potential contaminants, which will increase their ability to act as a solvent.

Thirdly, consider what level of corrosion protection is required. Humidity generally only becomes problematic when condensation occurs, which would require close attention to the thickness and coverage of the coating. But do remember, while a thicker coating might provide superior protection in condensing environments or where salt-spray or corrosive gases are present, anything deeper than the 50 micron target thickness may be prone to cracking under conditions of thermal shock or thermal cycling.

How important is the application method to the reliability of coatings?

This is probably the number one determinant of success. Often a poor material applied well, can be just as good or sometimes better than a material with great properties, that is applied badly. Coating is about getting sufficient coverage of the sharp edges and metal surfaces without applying the material too thickly elsewhere. Of course, some materials ‘apply better’ than others and make this process as easy and foolproof as possible; ultimately, the performance of liquid applied coatings will always be determined by how well they were applied.

Understanding Coating Values

When choosing a conformal coating, designers should be aware that the values listed in a vendor data sheet are generally for ambient conditions for newly cured coatings. Designers need to be aware of how the behaviour of materials will vary with temperature and time. Temperature excursions will also need to be factored in, for instance, if thermal shock or thermal cycling is overlooked, it could lead to cracking.

Simplify board layout

By the ‘simple’ act of placing connectors and components that must not be coated along one edge of the assembly, the conformal coating application process will be simplified. It is also advisable to avoid large arrays of discrete components, which can pose a huge coating challenge due to the high levels of capillary forces present. Similarly, tall components present challenges of their own by the creation of shadowed or hard to reach areas. Splashing is another associated problem. The trick is to avoid placing tall components next to ‘must-coat’ components in order to avoid this eventuality.

Know Your Components

Knowing your components is central to achieving a successful coating process. Simply by being aware of what kinds of components should be coated or should not be coated will provide more flexibility to the coater in assembly operations. When a component will not be coated, it becomes a ‘keep out’ zone. The engineering drawing should not only identify components but identify the tolerance on that keep out zone. It is important to be very specific on tolerance. The manufacturer needs to know exactly where you want coating and where you don’t want coatings. It is best practice to specify the areas that need to be coated and the areas that don’t as well as the ‘don’t care’ areas to help the coating process run as smoothly as possible. Avoid vague statements at all costs in an engineering drawing. This is especially true when specifying coating around connectors.

Be mindful of the processes that can affect the coating

It is important to be aware of what kinds of manufacturing practices may occur following the application and cure of the coating, as other materials such as thermal greases/putties and rework/repair chemicals, can all have an impact on the integrity and overall performance of a coating. When selecting adhesives for assemblies, do ensure that they are compatible with the selected coating materials and processes. Incompatible adhesives can have a detrimental effect on the overall performance of the coating.

The importance of pre-coat cleaning

The overall cleanliness of the substrate or the potential presence of residues on the substrate will have a critical impact on coating performance. If the substrate is not adequately clean, the residues present may interfere with the curing mechanism, lead to poor adhesion of the coating to the substrate and trap conductive/ionic materials under the coating. Without meticulous attention to preparation or pre-coat cleaning regimes, corrosive residues bridging the PCB’s conducting tracks can cause failures over time.

Create a buffer to make coverage easier for production

Conformal coatings are usually liquid when applied and will flow with a combination of gravity and the capillary forces present. Understanding and controlling this behaviour, and its effect on conformal coating coverage, will be key to the performance of coated assemblies operating in harsh environments. So, whether the process specifies masking or a reliance upon the process of selective conformal coating, a production team will be greatly relieved if you leave a buffer of at least 3mm clear between the areas that must be coated. This small buffer will make the production process easier and prevent future issues in production.

Getting Coating Thickness Right

Achieving the correct coating thickness is essential; bear in mind that if the coating is too thick it can lead to entrapment of solvents in areas where the coating does not fully cure. Similarly, it can cause the coating to crack as it cures or as the result of changes in temperature, or due to mechanical shock and vibration. Conformal coatings should not be applied in thicknesses greater than necessary or exceed the thickness they were designed to be applied at.

How important is the re-workability characteristic of a coating?

Re-workability of a coating can often be a very important consideration in the selection of a conformal coating, especially when boards are of high value, and have long service life expectancies, e.g. Military and Aerospace assemblies. A coating may display many favourable characteristics that make it superior for assembly protection in the field, but may also make the assembly very difficult to rework or repair in the field. A difficult-to-rework coating will not only make repairs and upgrades time consuming, but will also add cost and complexity to the product.

It’s all about the cure

The cure mechanisms of the main classes of coating materials are drying, oxidative, moisture, heat, chemical and UV. Choice will depend on a variety of factors such as the performance requirements of the application and physical constraints, including the maximum permissible cure temperature and the time allotted for curing. The cure time in particular varies dramatically for each mechanism. For instance, oxidative cure can have a longer cure time, often requiring many hours at 80-90°C to develop optimum properties, whereas, UV curable materials such as Electrolube’s UVCL range, cure extremely rapidly (in seconds) when exposed to UV radiation of a suitable wavelength and intensity. If in any doubt about cure mechanisms, do talk to your coating vendor.

What are the reasons for coating failure?

Coatings fail for any number of reasons – some common and some not so common. The fundamental reasons for failure are generally the result of poor product selection and/or application, or some underlying problem arising from insufficient surface preparation or some chemical activity going on beneath the coating that is entirely unrelated to the coating chemistry. Further potential reasons may also include insufficient cure time, poor coverage or insufficient thickness, an unexpected interaction with another process material or there is something else going on that isn’t directly related to the coating, such as corrosive residues bridging the PCB’s conducting tracks can, over time, cause failures.

Protecting against condensation, immersion and salt-spray

The greatest test of coating performance is posed during power-up under wet conditions, whether this is due to condensation, immersion or salt-spray. Liquid water with soluble impurities is electrically conductive and, finding any weak spots in a coating, will eventually lead to short-circuits at the PCB surface. In order to provide protection in these circumstances, it is essential to achieve 100% defect-free coverage of the PCB’s metal surfaces, and this poses a real challenge for both the material itself and the application process.

A new class of conformal coating materials dubbed ‘2K’ enable a much greater thickness and perfect application coverage to be achieved, resulting in a higher level of protection. Electrolube’s 2K materials have been positively demonstrated in the harshest possible tests, including powered condensation testing and powered immersion testing in salt-water.

Coating Cycle Time

Coating cycle time is clearly very important to the balance of the production line, so what kills coating quality and cycle time on a typical selective coating line?

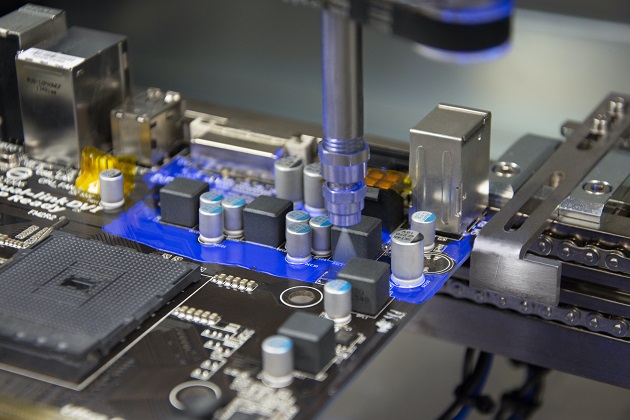

Selective coating machines deposit a stripe of coating material that can be programmed to stop and start on demand. Stripes of coating can be deposited to create a coating pattern, avoiding areas such as switches, connectors and test points, which must not be coated to prevent interference with form, fit or function. The coating stripes are usually in the 8-15mm range. When the area to be coated is less than 8mm in width, then it is necessary to utilise a dispensing step, which is a cycle time killer.

Due to the combination of machine X/Y positional accuracy, material fluid dynamics and component topography, 2-3mm is usually as close to keep out areas as anyone would be comfortable coating for a repeatable process. So must coat and keep-out areas within 2-3 mm of each other present a problem and again dispensing will be required, another process step which kills cycle time.

Test, test and test again

Environmental testing is key to ensuring that coatings are fit for purpose and will stand up to the most rigorous of conditions. Environmental testing includes extremely high and low temperatures; rapid excursions of temperature sufficient to impose thermal shock; salt spray and salt fog; very high humidity or condensing conditions; saturated environments; exposure to fungal growths, corrosive gases and solar radiation, and high and low atmospheric pressures (especially for aeronautical and space equipment). In reality, a coated board will be subjected to a variety of environmental impacts, not just one. The conditions and exposures should be chosen to be representative of what could reasonably be expected in a real life, end-use environment.

When design and production work together, the outcome will nearly always be successful. Having explored the importance of making sound early-stage design decisions, it is important to understand “what effects what” on the surface of the board to ensure successful conformal coating is achieved. Implementing these lessons will prevent potential production disasters not only with conformal coatings, but also in other areas of production as well. In short choose the right material for the protection required, apply it appropriately and cure it well. Check for interactions with other process chemistries, and thoroughly clean and dry the assembly prior to coating, and ultimately you will establish a solid and reliable electronic assembly process.